The Latest Chieftain Promise ell

Page 68

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

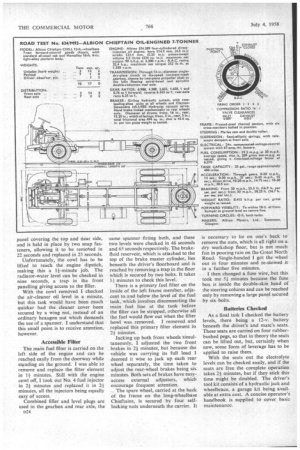

Carrying 7 Tons, New Albion Chieftain Gives 19.2 m.p.g. at 30 m.p.h. Average Speed: Acceleration and Handling Good: Cab Comfort Reaches High Standard By John F. Moon,

NY OT only is the new Albion Chieftain, announced today, much more comfortable to drive than i s predecessor, but its performance and design also reflect considerable research into the provision of even better overall operating economy. This is no small feat in view of ,the reputation of the earlier model for low-cost haulage. Its low price is a further important advantage.

Running over an undulating 10-mile. course and loaded to 10 tons 17 cwt. gross, it returned 19.2 m.p.g. at an average speed of 30 m.p.h., giving the exceptionally good time-load-mileage factor of 6,270. The economy of the new Chieftain does not end there, however, as the chassis has been designed to give long trouble-free life.

Evidence of this purpose is found in the use of a new design of heavy-duty front axle, a new double-reduction rear axle, larger brakes and a de-rated 100 b.h.p. engine. Thus, even allowing for inevitable overloading, the vehicle will be working well within its design limits.

Fully described on pages 760-763, the Chieftain range comprises four models of varying wheelbases. The 12-ft. wheelbase version was offered for test. This was equipped with the standard all-steel cab and Homalloy 16-ft. 6-in, light-alloy platform body, the kerb weight of the complete vehicle being 3 tons 124: cwt.

A test load of 7 tons 1 cwt. had been added and this, together with myself an'd Albion driver aboard, brought the gross running weight to 13 cwt. more than the figure officially recommended by the manufacturers for standard tyres. Despite this overload, the chassis performance was appreciably better than that normally experienced with vehicles in the 6-7-ton payload class.

D22 For the first series of tests the Chieftain was headed north from Glasgow and at Ruchlyvie, on the ,GlasgowStirling Road, it was stopped and the fuel test tank connected. From this point a fast 10-mile run was made in the direction of Stirling, the driver keeping the speed around the 35 m.p.h. mark wherever possible and making full use of the overdrive top, gear, an optional extra fitted to the test chassis.

At the end of the run the amount of fuel used was measured, giving an overall consumption figure of 19.2 m.p.g., the distance having been covered in exactly 20 minutes. The route was a reasonably easy .one, although traffic encountered during the run tended to impede our progress, and on normal trunk work with a fully run-in vehicle, figures of this order might be expected.

Two sets of comparative figures were then taken to assess the effect of the overdrive ratio-on fuel economy. This showed that, when engaged on normal give-and-take operation, an improvement of approximately 7 per cent, could be expected by the addition of the-extra ratio.

The standard chassis, with directtop drive would give about 17-18 m.p.g. in service, with an improvement of about 1 m.p.g. if the speed were not increased, when the overdrive . was fitted and used for economy. The advantage of the overdrive ratio does not end there, however, as it also ensures a lower engine speed at the same road speed, with subsequent , wear reduction, and quieter running.

Another worthwhile point is that the maximum speed of the chassis with the standard 6.25-to-1 rear axle •is raised from 39 m.p.h. with direct drive to 52 m.p.h. with overdrive. .

Braking and acceleration tests were carried out along the level Stirling Straight. Although, because of rearwheel locking, the braking figures were no better than those obtained five years ago with the previous version of the Chieftain, the system employed on the new chassis gives the same retardation at lower pedal pressures, in addition to possessing distinctly better anti-fade characteristics. The hand brake was extremely, effective in an emergency, an average Tapley meter reading of 311 per cent. being obtained from 20 m.p.h.

Lively Acceleration Good acceleration figures were obtained both through the gears and in direct drive. For the standing-start tests all the gearbox ratios except bottom were employed, whilst for the direct-drive runs fifth gear was used,. the engine and transmission turning. perfectly smoothly in this ratio from 8 m.p.h.l upwards.

Gleniffer Braes, Paisley, a 1.2-mile climb with an average gradient of 1 in 13, was used for testing engine power. and coOling; and brake" fade. The_ ambient temperature at the time of the ascent Was 66 F. and the engine' coolant temperature at the header tank was 166° F. The climb took seven minutes and the speed for the most part was 10-12 m.p.h. in third and fourth gears; the lowest ratio engaged was second, this being necessary for only 11 seconds.

At the top of the hill a check showed that the coolant temperature had risen by only 2° F. This small increase is partly attributable to a slight headwind, because the engine was turning at low revolutions for much of the ascent.

The rear-axle oil was at 126° F., which is very low for a climb of this nature, and serves to substantiate the claim of the manufacturers that this new double-reduction unit has ample capacity for continuous full-torque transmission. As this torque is divided between the bevel gearing and the hub gears, none of the component parts is likely to be overstressed, even on tipper work..

After turning the chassis in a narrow gateway—a manceuvre made easy by the good steering lock, which gives a turning circle of only 45 ft.—the chassis was coasted down the hill in neutral, the foot brake being used to restrict the speed to 20 m.p.h. This descent lasted four minutes and a full-pressure stop from 20 m.p.h. showed that the braking efficiency had been reduced by only 0.25 g., indicating good fade resistance in view of the severity of the test.

• A stOp-and-start was made on the 1-in-6 gradient of Gardner. Street, in the centre of Glasgow. The hand brake held it safely without assistance from the foot brake, after which a smooth first-gear re-start was made with neither clutch slip. nor transmission roughness.

At no time during either this test or the ascent of Gleniffer Braes was any smoke noticed at the exhaust outlet, showing the wisdom of de-rating this unit from the maximum of 100 b.h.p., so that it can operate in the Chieftain at 90 b.h.p. without being stressed to its maximum.

In general handling, the new Chief-. tam n is one of the best 7-tonners I have tested. The driving position is firstclass, as is the general all-round visibility, and the driving seat is adjustable vertically, horizontally and for rake. Access to the cab would delight any operator of delivery vehicles; the wide door opens through more than 90° and there are only two steps up, each one being about 19 in.

The layout of the controls is good, the pedals being well spaced. Similarly, the gear lever, the travel of which is Short, is cranked so that it lies close to the driver's left hand, whilst the handbrake position is such that a really powerful purchase can be obtained on it.

Good Cornering

The use of 54-in.-long front springs and telescopic dampers ensures a high standard of ride and good cornering characteristics, and the light, selfcentering steering combines to allow the Chieftain to be taken through sharp corners more in the style of a sports car.

Engine noise is reasonable, although there is no disguising the fact that the power unit is a big "four," and the cab was commendably free from vibration and rattles. All the instruments, except the speedometer, are electrically operated and have British and metric calibrations. Good ventilation is provided and standard fittings include a cab interior light and twin self-parking electric windscreen wipers.

Maintenance tests revealed a generally high standard of accessibility. The engine cowl has a large detachable panel covering the top and near side, and is held in place by two snap fasteners, allowing it to be remeetred in 22 seconds and replaced in 25 seconds.

Unfortunately, the cowl has to be lifted to reach the engine dipstick, making this a 1+-minute job. The radiator-water level can be checked in nine seconds, a trap in the front panelling giving access to the filler.

With the cowl removed I checked the air-cleaner oil level in a minute, but this task would have been much quicker had the cleaner cover been secured by a wing nut, instead of an ordinary hexagon nut which demands the use of a spanner. I understand that this small point is to receive attention, however.

Accessible Filter The main fuel filter is carried on the left side of the engine and can be reached easily from the doorway while standing on the ground, I was able to remove and replace the filter element in 14. minutes. Still with fife engine cowl off, I took out No. 4 fuel injector in 24, minutes and replaced it in 21 minutes, all the injectors being equally easy of access.

Combined filler and level plugs are used in the gearbox and rear axle, the D24 same spanner fitting both, and these two levels were checked in 46 seconds and 65 seconds respectively. The brakefluid reservoir, which is attached to the top of the brake master cylinder, lies beneath the driver's floorboard and is reached by removing a trap in the floor which is secured by two bolts. It takes 14 minutes to check this level.

There is a primary fuel filter on the inside of the left frame member, adjacent to and below the level of the fuel tank, which involves disconnecting the main fuel line at the tank before the filter can be stripped, otherwise all the fuel would flow out when the filter bowl was removed. I removed and replaced this primary filter element in 24 minutes.

Jacking up both front wheels simultaneously, I adjusted the two front brakes in 2+ minutes, but because the vehicle was carrying its full load I deemed it wise to jack up each rear wheel separately, the time taken to adjust the rear-wheel brakes being six minutes. Both sets of brakes have easyaccess external adjusters, which encourage frequent attention.

The spare wheel, carried at the back of the frame on the long-wheelbase Chieftains, is secured by four selflocking nuts underneath the carrier. It is necessary to lie on one's back to remove the nuts, which is all right on a dry workshop floor, but is not much fun in pouring ram on the Great North Road. Single-handed I got the wheel out in four minutes and re-stowed it in a further five minutes.

I then changed a fuse wire, but this took me 51 minutes because the fuse box is inside the double-skin head of the steering column and can be reached only by removing a large panel secured by six bolts.

Batteries Checked As a final task I checked the battery levels, there being a 12-v. battery beneath the driver's and mate's seats. These seats are carried on four rubberbushed pegs, so that in theory the seats can be lifted out, but, certainly when new, some form of leverage has to be applied to raise them.

With the seats out the electrolyte levels can be checked easily, and if the seats are free the complete operation takes 21 minutes, but if they stick this time might be doubled. The driver's tool kit consists of a hydraulic jack and wheelbrace, a garage kit being available at extra cost. A concise operator's handbook is supplied to cover basic maintenance.