WHY SUPERHEATERS ARE NECESSARY.

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

The Advantages Gained by Fitting Superheaters to All Types of Steam Tractors and Over-type and Under-type Steam Wagons.

THE OBJECT of superheating the steam before entering the stop valve chest is to secure dry steam in the cylinder; and the gain by using super. heated steam is due to the complete removal of the loss due to initial condensation which occurs in engines taking steam direct from the boiler.

Superheating is accomplished by supplying the steam generated in the boiler with heat from the waste gases in the smoke-box, which would otherwise ascend the chimney with no useful purpose. Considering the amount of heat in the smoke-box gases (which are at an average temperature of from 700 degrees Fahr. to 800 degrees Fahr.), and the fact that. it is possible to utilize this heat, it is obvious there must he a reduction in the fuel costs if a smoke-box superheater be fitted. .

The temperature of the cylinder walls with saturated steam is below that of the steam entering the cylinder, but when the steam is superheated to 150 degrees Fahr. above the temperature at which it comes from the boiler, it can part with some of its surplus heat, and still retain a certain amount of dryness. Therefore it follows that the drier the steam in at the cut-off the more the work that must be done on the piston per pound of steam, due to the removal of water in the cylinder, thus ensuring a reduced fuel bill and water consumption. It is in the interests of owners of either one tractor or wagon, or a fleet, to run the vehicle or vehicles as economically as possible, and tractors or wagons with superheaters will give as much as 20 per cent. saving on fuel, and 25 per cent. saving on water. Moreover, there will be an increased radius of action, which is appreciable in long-distance journeys. Cheaper running for snore mileage should be the owner's maxim.

Superheaters, as fitted to present-day type road vehicles, are disposed in the smoke-box, and sufficient heating surface can be obtained without any increase of length of a tractor or wagon not fitted with one. It is also possible to provide a superheater which will stilt keep a clear way to clean the boiler tubes. In well. designed superheaters, provision is made whereby the tubes can be cleaned with the ordinary steam. boiler cleaning apparatus. With the use of such a fitting, special attention must be paid to lubrication, but good lubricants for high temperature steam are on the market, and with forced lubrication there is not much fear that the stuffing boxes and pistons will become scored.

Theoretically, there should be a head • of temperature, between the smoke-box gases an the steam, of approximately 370 degrees Fahr. in order that the superheater heating surface may be efficient. Under ordinary conditions, a heat transmission of about. 5 B.T.U. per sq. ft. of heating surface per hour per degree difference of temperature is obtained, the latter being taken as the difference between the mean temperature of the smoke-box gases and of the steam respectively before entering and after leaving the superheater.

For example, assume the temperature of the smoke-box gases to be 800 degrees Fahr. and the superheated steam 532 degrees Fahr. ; that is, raising the steam to

a temperature of 150 degrees Fahr. higher than the saturation temperature with a working pressure of 200 lb. per sq. in. Therefore, each sq. ft. of heating surface in the superheater will transmit 5 x (800 — 532) = 1340 B.T.U. per hour. Assuming a 20 b.h.p. tractor and a steam consumption of 20 lb. per b.h.p. hour, the steam generated would equal 400 lb. The heat required will be, taking the specific heat of superheated steam as 0.475, 400 x150 x0.475=28,500 B.T.U. per hour.

As each sq. ft, of heating surface with this difference of temperatures transmits 1,340 B.T.U. per hour, the total heating surface required to superheat to 150 degrees Fahr. will be 28500÷1340, or approximately 21 sq. ft.

The following figures give a fair idea of the gain by superheating.

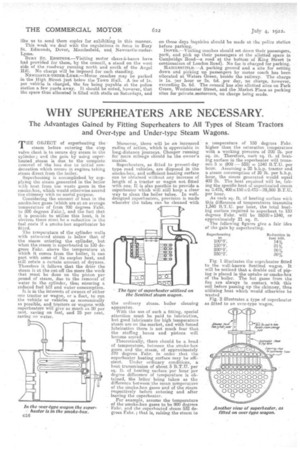

Fig. 1 illustrates the superheater fitted to the well-known Sentinel wagon. It will be noticed that a double coil of piping is placed in the uptake or smoke-box of the boiler. The hot gases from the fire are always in contact with this coil before passing up the chimney, thus utilizing heat which would otherwise be wasted Fig. 2 illustrates a type of superheater as fitted to an over type wagon.