GREEN CLEAN EAN MACHINE

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Engineers at Navistar in the USA have redesigned the familiar D-466 diesel engine to meet the new US particulate emission level set for 1994. But it will have to use low-sulphur fuel.

• "File sulphur content of diesel fuel will have to be slashed from 0.3% to just 0.06% if exhaust gas particulate levels are to comply with the American 0.1g/hp-hr limit scheduled levels for 1994.

That is the view of diesel engineers at Navistar, (formerly International Harvester), the largest US truck manufacturer above six tonnes. They have revamped the 7.6-litre in-line six cylinder D-466 engine, which was used for several years in Seddon Atkinson's 300 Series chassis. Prototypes of the new engine, designated NGD-466, meet the 1994 target when fitted with catalytic converters — but only running on low-sulphur-content fuel.

Running on standard diesel fuel and without a converter the NGD-466 has a particulate level of 0.17glip-hr. Great attention has been paid to oil control as partially-burned lubrication oil has been found to contribute substantially to particulates. Redesigned piston rings are used, and each valve guide incorporates a new non-metallic seal to prevent oil seeping into the combustion space.

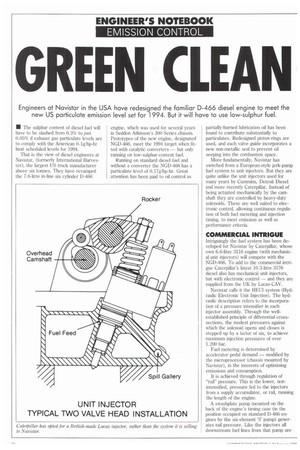

More fundamentally, Navistar has switched from a European-style jerk-pump fuel system to unit injectors. But they are quite unlike the unit injectors used for many years by Cummins, Detroit Diesel and more recently Caterpillar. Instead of being actuated mechanically by the camshaft they are controlled by heavy-duty solenoids. These are well suited to electronic control, allowing continuous regulation of both fuel metering and injection timing, to meet emission as well as performance criteria.

COMMERCIAL INTRIGUE

Intriguingly the fuel system has been developed for Navistar by Caterpillar, whose own 6.6-litre 3116 engine (with mechanical unit injectors) will compete with the NGD-466. To add to the commercial intrigue Caterpillar's latest 10.3-litre 3176 diesel also has mechanical unit injectors, but with electronic control — and they are supplied from the UK by Lucas-CA V.

Navistar calls it the HEUI system (Hydraulic Electronic Unit Injection). The hydraulic description refers to the incorporation of a pressure intensifier in each injector assembly. Through the wellestablished principle of differential crosssections, the modest pressures against which the solenoid opens and closes is stepped up by a factor of six, to achieve maximum injection pressures of over 1.200 bar.

Fuel metering is determined by accelerator pedal demand — modified by the microprocessor (chassis mounted by Navistar), in the interests of optimising emissions and consumption.

It is achieved through regulation of "rail" pressure. This is the lower, nonintensified, pressure fed to the injectors from a supply accumulator, or rail, running the length of the engine.

A swashplate pump mounted on the back of the engine's timing case (in the position occupied on standard 0-466 engines by the six-element 'fi' pump) generates rail pressure. Like the injectors all downstream fuel lines from that pump are enclosed within the engine, many of them as drillings, and as such are hidden from view, making for an exceptionally clean installation.

Because metering and timing are mechanically independent of the engine — a magnetic pickup on the flywheel provides a liming datum --fuelling characteristics can be programmed in the electronic 'black box without the constraints of varying engine speed imposed, as in all previous diesel fuel systems, on pressure and timing. In particular Navistar is able to tailor the NGD-466's torque output precisely. That full injection pressure of over 12,000 bar is available at only half speed.

Surprisingly, a standard Garrett turbocharger is employed with fixed geometry. Variable geometry could come later, says technical director John Horne, if emission legislation gets tighter.

Research by Navistar on combustion chamber shape has led to the latest engine's re-entrant chamber being nicknamed the 'golf-ball'. It is said to reduce visible smoke and particulates at a constant nitrogen oxides (N0x) level. Also, the top lip of the chamber in the Zolner pistion is claimed to he more resistant to cracking over a long life.

Outputs of up to 224kW (300hp) are planned for the NGD-466 engine, which Navistar intends to launch in its truck chassis in 1992. Above 157kW (210hp) they will feature air-to-air charge-cooling.

Computer-aided design of the cylinder block and head has removed a good deal of weight from the original D-466. Together with the fuel system changes, it has cut weight by some 90kg, to 545kg.

DIFFERENT SYSTEM

It remains a mystery why Caterpillar should have developed and used the HEUI fuel system, only to supply it to Navistar, while at the same time using a quite different system bought in from Lucas in the UK for its own new 10.3-litre 3176 diesel.

Lucas Diesel Systems engineers who have worked closely with Cat through the 1980s say they suspect the HEUI or accumulator system proved too complicated and too costly for Caterpillar to use in its own engines.

There was also thought to be a question mark against the durability of the solenoid actuation of the injectors and the resistance to leaks of the long galleries and connections held at relatively-high "rail" pressure. LDS's chief engineer, George Frankl, says accumulator operation was pursued experimentally in the early eighties by the company when it became apparent that higher injection pressures would be called for, under more precise control, to meet

upcoming emission and fuel economy demands. But, says Frankl, it was eventually dismissed in favour of the mechanicallyactuated electronically-controlled EUI system, eventually adopted by Cat. 111 by Alan Bunting