Slowly does it Until now many hauliers have regarded retarders

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

as an expensive piece of kit although there are important safety aspects. But now EC legislation will force a change of heart—Scania is ready for them.

British truck operators have never really taken to retarders. Maybe the manufacturers tried too hard to sell them on the grounds of safety Most hauliers are motivated less by safety than by money and £4,000 is a lot to pay for a heavy lump of metal just for some extra braking.

Show them wear savings on linings and drums, and faster journey times through hilly terrain, and you're talking their language.

But now EC legislation looks set to force UK hauliers, or at least those carrying hazardous goods on international routes, to re-consider the retarder option.

HAZARDOUS More significantly, the DOT is committed to harmonising the regulations by 1 January 1995, meaning that new hazardous goods vehicles running within the UK will also require endurance braking systems. Older vehicles will have to be retrofitted by 1 January 2000.

These rules may have prompted Scania to produce its own hydraulic retarder, which was shown last October at the Maastricht Bus Show and launched on trucks at the Brussels Show (CM21-27 Jan). According to Scania (Great Britain)'s product marketing manager David Burke: "We always want to be ahead of legislative deadlines, that's why we had Euro-1 engines last year, well before the October deadline this year."

The hydrodynamic retarder was developed for the GR900 and GRS900 nine and 16-speed Scania transmissions. Like ZF"s Intarder, it's built into the rear of the box and driven via a gear train from the output shaft with a ratio of 2:1. Retardation is provided by a hydrodynamic vane. The level of braking is dependent on the amount of hydraulic fluid in the circuit but a pressurised hydraulic accumulator allows the vane to be charged extremely quickly.

Like the Voith retarder the Scania secondary brake has a hydraulic fluid/coolant heat exchanger which is part of the truck's cooling system, although the retarder has its own lubrication system separate from the gearbox. Duplicate valves are used throughout the system so if a valve fails the retarder can be disengaged. Heat is a by-product of any retarder. Unlike device which reduces the braking power before overheating can occur.

Depending on coolant flow the Swedish retarder can deliver up to 650kW of braking power. The average operator will be nitre interested in Scania's claim that brake lining life is extended by up to 600%. Brake drum wear is also said to be "significantly reduced".

As an in-house device the Scania retarder runs with standard prop-shafts but it can't be specified on a twin-steer tractor as there isn't enough room to fit it around the. second steering axle.

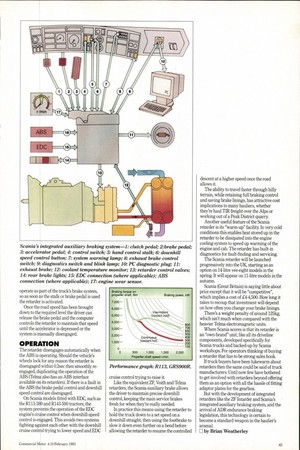

IMPRESSIVE Perhaps the most impressive aspect of the Scania retarder is the level of braking control which it offers to the driver. It is operated by a five-position lever on the dashboard or, on ABS-equipped trucks,via the brake-pedal. The exhaust brake is integrated into the system and the microprocessor control unit controlling the whole shooting match is also linked into the ABS and EDC (electronic diesel control) functions to co-ordinate their functions.

Like the more sophisticated Voith units it has a downhill speed control feature which is activated when a button on. the end of the dashboard lever is pressed at a set speed, or when the vehicle is braked using the foot brake. The retarder then maintains the desired speed as the vehicle runs downhill. Pressing the throttle pedal disengages the downhill speed control but when the clutch pedal is depressed the retarder stays in operation to hold the speed down during downshifts.

A switch in the dashboard allows brake-pedal speed control via the retarder and the conventional exhaust brake. The brake pedal operation of the downhill speed control allows the retarder to operate as part of the truck's brake system, so as soon as the stalk or brake pedal is used the retarder is activated.

Once the road speed has been brought down to the required level the driver can release the brake pedal and the computer controls thEi retarder to maintain that speed until the accelerator is depressed or the system is manually disengaged.

OPERATION The retarder disengages automatically when the ABS is operating. Should the vehicle's wheels lock for any reason the retarder is disengaged within 0.2sec then smoothly reengaged, duplicating the operation of the ABS (Telma also has an ABS interface available on its retarders). If there is a fault in the ABS the brake pedal control and downhill speed control are disengaged.

On Scania models fitted with EDC, such as the R113-380 and R143-500 tractors, the system prevents the operation of the EDC engine's cr 'se control when downhill-speed control is e gaged. This avoids two systems fighting ag4inst each other with the downhill cruise contrl trying to lower speed and EDC cruise control trying to raise it.

Like the equivalent ZF, Voith and Telma retarders, the Scania auxiliary brake allows the driver to maintain precise downhill control, keeping the main service brakes fresh for when they're really needed.

In practice this means using the retarder to hold the truck down to a set speed on a downhill straight, then using the footbrake to slow it down even further on a bend before allowing the retarder to resume the controlled descent at a higher speed once the road allows it.

The ability to travel faster through hilly terrain, while retaining full braking control and saving brake linings, has attractive cost implications to many hauliers, whether they're haul TIR freight over the Alps or working out of a Peak District quarry.

Another useful feature of the Scania retarder is its "warm-up" facility. In very cold conditions this enables heat stored up in the retarder to be dissipated into the engine cooling system to speed up warming of the engine and cab. The retarder has built-in diagnostics for fault-finding and servicing.

The Scania retarder will be launched progressively into the UK, starting as an option on 14-litre vee-eight models in the spring. It will appear on 11-litre models in the autumn. • Scania (Great Britain) is saying little about price except that it will be "competitive", which implies a cost of £44,500. How long it takes to recoup that investment will depend on how often you change your brake linings.

There's a weight penalty of around 125kg, which isn't much when compared with the heavier Tehna electromagnetic units.

Where Scania scores is that its retarder is an "own-brand" unit, like all its driveline components, developed specifically for Scania trucks and backed-up by Scania workshops. For operators thinking of buying a retarder that has to be strong sales hook.

If truck buyers have been lukewarm about retarders then the same could be said of truck manufacturers. Until now few have bothered to get involved with retarders beyond offering them as an option with all the hassle of fitting adaptor plates for the gearbox.

But with the development of integrated retarders like the ZF Intarder and Scania's • integrated auxiliary braking system, and the arrival of ADR endurance braking legislation, this technology is certain to become a standard weapon in the haulier's arsenal.

D by Brian Weatherley