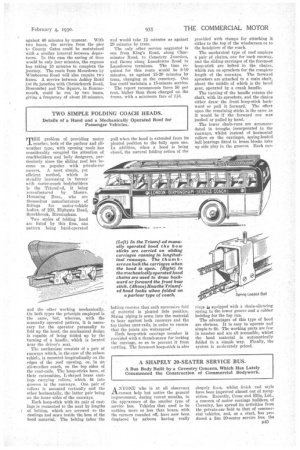

TWO SIMPLE FOLDING COACH HEADS.

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a Hand and a Mechanically Operated Roof for Passenger Vehicles.

T'Eproblem of providing motor coaches, both of the parlour and allweather type, with opening roofs has considerably occupied the attention of coachbuilders and body designers, particularly since the sliding roof has become so popular with private-car owners. A most simple, yet efficient method, which is steadily increasing in favour • with motor-coach bodybuilders is the Triumf-ed, it being manufactured by Messrs. Hemming Bros., who are themselves manufacturers of fittings for motor-vehiele bodies, of 233, Highgate Road, Sparkbrook, Birmingham. Two styles of• folding head are listed by this firm, one pattern being hand-operated and the other working mechanically. On both types the principle employed is the same, but, whereas, with the manually operated pattern, it is necessary for the operator personally to fold up the hood, the mechanical design is capable of being folded up by the turning of a handle, which is located near the driver's seat. The mechanism consists of a pair of runways which, in the case of the saloon vehicle, is mounted longitudinally on the edges of the roof opening, or, in an all-weather coach, on the top sides of the cant-rails. The hoop-sticks have, at their extremities, L-shaped brass castings carrying rollers, which fit into grooves in the runways. One pair of rollers is mounted vertically and the other horizontally, the latter pair being on the inner sides of the runways. Each hoop-stick with its pair of castings is connected to the next by lengths of belting, which are screwed to the castings and sewn inside the hem of the hood material. The belting takes the pull when the hood is extended from its pleated position to the fully open one. In addition, when a hood is being closed, the natural folding action of the belting ensures that each successive fold of material is pleated into position. String piping is sewn into the material to bear against both runways and the top timber cant-rails, in order to ensure that the joints are waterproof. Each hoop-stick carriage member is provided with a thumb-screw for locking the carriage, so as to prevent it from rattling. The foremost hoop-stick is also provided with clamps for attaching it either to the top of the windscreen or to the headpiece of the coach. The mechanical type of roof employs a pair•pf chains, one. for each runway, and the sliding carriages of the foremost hoop-stick are bolted to the chains, which run on sprockets for the complete length of the runways. The forward sprockets are attached to a main shaft, about the middle of which is the bevel gear, operated by a crank handle. The turning of the handle rotates the shaft, with its sprockets, and the chains either draw the front hoop-stick backward or pull it forward. The effect upon the remaining sticks is the $anne as it would be if the forward one was pushed or pulled by hand. chain-runs lower cha-runs are accommodated in troughs incorporated in the runways, whilst instead of horizontal rollers on the carriages, spring-loaded ball bearings fitted in brass blocks take up side play in the grooves. Each car riage is equipped with a chain-silencing spring hi the lower groove and a rubber bedding for the top run. The advantages of this type of hood are obvious. It is easy to operate and simple to fit. The working parts are few in number and are all accessible, whilst the hood material is automatically folded in a simple way. Finally, the system is moderately priced.