The Road Performance o A POPULAR Six-wheeled STEAM WAGON

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

A Sentinel Machine Tested Under Difficult Weather Conditions : Low Fuel Consumption Despite High Tractive Resistance

IN heavy-transport circles the desigaation D06 has beaome so well known that the word " Sentinel" in conjunction With it is often considered

unnecessary. For pay-loads of 12-15 tons this machine has proved to be a most economical and reliable unit.

We recently took an opportunity for subjecting to the standard test of The Commercial Motor it DG6 wagon, fully laden and in standard trim. The vehicle was practically new, having covered only a comparatively small mileage in the course of preliminary testing. The engine had first been run for a period of about half an hour to threequarters of an hour without load in order to ease the bearings prior to test. This procedure is adopted in the ease of all new Sentinel engines.

Weather conditions were extremely unfavourable for our test; the morning was very cold and a fog, which persisted until late in the afternoon, made it very difficult to obtain good visibility, whilst the exhaust steam tended to hang around the wagon. It was difficult to see far ahead, but this, of course, showed to advantage the controllability of the machine. Owing -to the damp state of the roads, tractive resistance was high throughout the day's running.

The first task was to carry out a fuel-consumption trial. For this purpose the boiler and water tank were drained so as to ensure a start from normal water tempera ture without any previous preparation. Fifty gallons of water

were fed to the boiler and 230 gallons to the main tank at the rear of the vehicle, whilst a separate tank, carried in the body, held 150 gallons. In this way it was possible to ensure that only a measured quantity of water could be used. The directly available quantity of water (without replenishment) was 380 gallons ; therefore the steaming range could be calculated by measuring the distance at which replenishment became necessary.

Next, eight bags of Windber steam coal were individually weighed and, including sacks, found to total 9 cwt. 2 qrs. 7 lb. Seven of these were stacked in the body of the vehicle and one bag was tipped into the bunker. In all 75 lb. of coal were used to raise steam to the working pressure of 275 lb. per sq. in. Twenty-five minutes after the fire had been lighted steam was registered on the gauge, the reading being 10 lb. at 30 minutes and 275 lb. at 50 minutes.

The Fuel Consumption Test.

In order to ascertain the fuel consumption a straight-out-and-home run was made. The Holyhead road was followed from Shrewsbury ; this has a very undulating contour and may be said to represent average going for mainroad transport purposes. At no point on this route was it necessary to use the lower gear, and, other than traffic stops and one for Water replenishment, there was only a cheek of about three minutes for photographic purposes at the half-way mark. The distance covered was 41.8 miles, and the vehicle was laden with 12 tons of iron blocks and the spare-Water tank.

During the fuel test the maximum speed attained was 27 m.p.h., but the normal cruising speed was in the neigh bourhood of 15-17 m.p.h., rising to 20-22 m.p.h. on slight down grades. The first 2i miles and the last 2i miles, through Shrewsbury and vicinity, involved traffic work. Naturally, the early cut-off position was used so far as possible—with this setting the engine operates most economically. There are three " forward " positions for the camshaft, and these are controlled by the outermost of three levers to the driver's right. In addition there is a neutral position in which all the valves remain open. Finally, there is a reverse position of the lever. On gradients up to about 1 in 10 the wagon pulled steadily with the lever in the second cut-off position, and it was only necessary to employ the late cut-off setting when the gradient became a single-figure one.

Comfort at Good Speeds.

One of the most striking qualifications of the DG6 on the • road was the comfort afforded to persons travelling thereon. Our representative walked amend the body when the vehicle was travelling at all speeds up to 25 m.p.h. and no jolting was experienced. A full sack of coal was used as a seat for about 30 miles ; no jars, such as to make this hard seat in any way an uncomfortable one, were transmitted by the front springs. Looking over the side of the body, the action of the bogie arms showed that the wheels were rising and falling under the influence of roadsurface variations, but the vertical movement of the rear end of the body was particularly small. The bogie pivot is situated so low that the amount of vertical rise of the pivot, occasioned by the wheels of the bogie passing over an obstruction, is unusually small.

Another feature which conduces to ease of riding is the flexibility of the frame, the side-members being designed to permit considerable movement.

After covering 37.4 miles the water in the boiler and main tank required replenishment, i.e., in the distance named the quantity of water consumed was 280 gallons, less, of course, the amount of water remaining in the boiler (about 50 gallons). In order to save time and prevent waste of fuel, the suction hose was fixed into the spare tank in the body and the water drawn into the main tank while the vehicle was travelling. The works were reached again after a journey of 41.8 miles, which occupied 3 hrs. 5 mins., giving an average speed, including the stops for photographs and water replenishment, of 13.6 m.p.h. The total fuel used proved to be 293 lb., from which 75 lb. was subtracted as the allowance for raising steam. This gave 218 lb. of coal for 41.8 miles, or 5.21 lb.

per mile. Assuming the coal to cost LI. 15s. per ton, the fuel cost per vehiclemile works out at .97d., or .08d. per

net ton-mile. Throughout the test steam pressure had been kept to 275 lb. per sq. in.

A separate run was undertaken for acceleration and braking tests, during the course of which a gradient of 1 ill 9 was climbed. The tractive resistance was considerable, on account of the soft nature of the road and the fact that the machine weighed well over 22 tons at the time. It was necessary to use the

late cut-off position on two occasions on the steepest part of the rise, but after a few yards the middle cut-off position was resumed. Near the crest of the hill the road surface changed from a soft one to a good tar-dressed macadam. Immediately the bogie wheels obtained a grip thereon the vehicle accelerated, showing that tractive resistance had been the most serious item in the climb. Top gear was used throughout. On low gear—and taking into account the fact that wheelspin can be precluded by the use of a differential lock—there is very little in the way of surfaces which have to be traversed in commercial practice which can stop the passage of the DG6. It will easily pull itself out of ruts or holes over a foot deep, and the exceedingly low speed at which it will move, when required, proves of great value in such circumstances as dense traffic or manceuvring in docks or quarries. The results of the acceleration test are shown in a graph reproduced on the previous page.

'Braking Capabilities.

The braking test was carried out with only the pedal-controlled steamoperated set. In case of emergency the pull-on hand brake could be used in conjunction with the steam set. The hand brake was used for parking purposes throughout the test, but the pedaloperated set was relied upon as a service brake and proved exceptionally sweet and powerful. A feature of this brake is that the driver can feel definitely what retarding effort he is applying to the wheels. The harder he depresses the pedal the greater resistance does he find. The roads throughout the test were wet and inclined to be slippery, but at no time did the vehicle deviate from its steered course.

'Silence in operation was one of the marked features of the day's runs. When on the level at about 17 m.p.h. the most appreciable sound emanated from the dynamo-driving chain. At speeds over 20 m.p.h. the exhaust was the most noticeable sound to those on the wagon, but when the observer took his seat in a car following the wagon the dynamo chain again became the only audible feature of the machine's run ning,. No vibration was experienced from the engine, except when it required an alteration of the cut-off.

The steam pressure was maintained evenly throughout the test ; the driver's mate attended solely to the stoking, which is effected through a chute passing vertically down the centre of the boiler. The controls are so grouped that the driver has them easily within reach ; the steering is surprisingly light for a machine of the size. This is possibly accounted for by the use of ballthrust bearings in the stub axles.

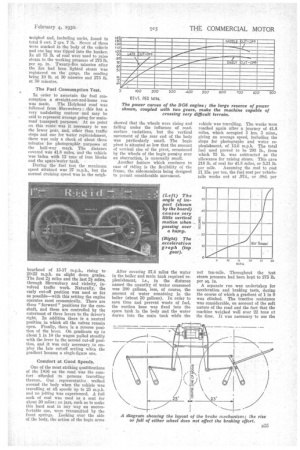

Features of interest in the performance of the wagon may be quoted, as they are particularly informative to those who are not familiar with steam traction. When the late cut-off is used there is 88 b.h.p. available when the engine is doing only 170 r.p.m. ; thus, it will be realized that there is an enormous reserve of latent power, however low the crankshaft speed may be. The maximum power with medium cute off is 120 b.h.p. at 550 r.p.m.

The rear suspension of the DG6 embodies compound springs, which permit easy riding when the vehicle is empty and give adequate support to the frame when the full pay-load is aboard.