ENGINE EFFICIENCY ENS] SUSTAINED TRANSOORT.

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

HE engine is the heart of the commercial motor chassis ; if it be kept in good order .many of the circumstances that lead to lass of vehicle service will be avoided. There are numerous owners and drivers of commercial vehicles who have very little more than a vague idea of the causes of engine troubles (mostly bearing troubles), whilst, even when some of the causes are known and partly understood, the knowledge which would lead to their removal is lacking. • A curious fact is that, although the power unit of a motor vehicle is realized as being its very heart, it is often sadly neglected, little attention being paid to it beyond the more or less regular supply of lubricant, the occasional grindingin of the valves and the adjustment of sparking-plug points. The consequence is that bearing troubles are rife, and it is with a view to assisting those connected with the running of petrol engines to eliminate

A typical white-metalled big-end bearing troubles, bearing, in which, in the case of so far as is reaoil shortage, the white metal will sonable, that "run," thus avoiding the worse this article has evil of seizing of the bearing, been written.

To day most Internal-combustion engines have .white-metal liners fitted to both Main and big-end crankshaft bearings to lessen the wear on the crankshaft journals, as well as to eliminate the possibility of a complete seizure of ri bearing, as would be the case were all gunmetal bearings to be fitted and run short of oil. Crankshafts can, of course, be reground on both main and big-end journals; but, if a considerable amount of wear has taken place, the crankshaft could, in all probability, only be reground twice during its useful life, as otherwise a further regrinding would reduce the diameter of the journals to below the safe limit. However, even with white-metal-lined bearings, which are, of course, much softer than gunmetal, it is surprising how much wear really takes place on the crankshaft journals, and on the bearing face of the bearings themselves. •

A white-metal-lined bearing gives out almost immediately the oil film between the white metal and the steel crankshaft journal has broken down and has allowed sufficient heat to develop to melt the white metal—which happens at a comparatively low temperature. The heat is created as the result of friction being set up between the bearing and the crankshaft journal in the absence of the oil film.

To understand lubrication one should look upon oil in a bearing as being a series of minute balls, which are practically frictionless and which arrange themselves between bearing and journal. Immediately the oil film fails, the metals come into direct contact and then considerable heat is developed.

Even with perfect bearing lubrication a certain amount of heat is always created, this being partially carried away by the oil; most of which returns to the crankcase sump after passing through the bearings. This applies to both main and big-end bearings. A certain amount of heat is also retained in the bearings and their housings. The remainder is either radiated through the adjacent metal or passes away through the breathers provided for the purpose of allowing crankcase gases, generated by the heating up of the oil, to escape.

Having explained the function of oil In the bearings it is necessary to give the various causes for the absence of sufficient oil in the main and bigend bearings. In the first place, there may be a general shortage of oil in the engine, due (1) to lack of proper replenishment when necessary, (2) to a leakage from a worn or loose drain plug, cock or joint, or (3) to a defective oil level indicator incorrectly registering a short quantity and thus deceiving the driver.

Secondly, a stoppage may take place in the oil circulation, due to foreign matter having collected

and formed an obstruction to the free passage of oil in the supply pipes. This, as a matter of fact, is the most frequent cause for a bearing giving out.

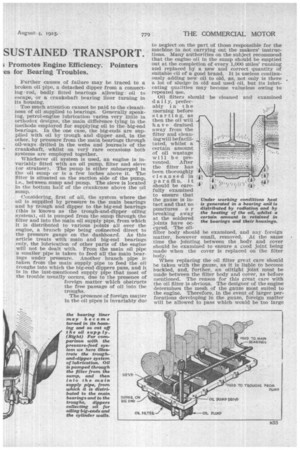

(Left) Oilways drilled through the crankshaft and webs to the crankpins, the oil being fed under pressure to the three main bearings and being carried into the shaft oilways as the shaft rotates. The presence of foreign matter in a supply pipe is a frequent cause of trouble. (Right) A few causes of failure in the lubrication system. A pipe may be broken, an oil scoop may become detached from a big-end cap, oil may leak past a badly fitting bearing, or

Further causes of failure may be traced to a broken oil pipe, a detached dipper from a connecting •rod, badly fitted bearings allowing oil to escape, or a crankshaft bearing liner turning in its housing.

Too much attention cannot be paid to the cleanliness of oil supplied to bearings. Generally speaking, petrol-engine lubrication varies very little in orthodox designs. the main difference lying in the methods employed for supplying oil to the big-end bearings. In the one case, the big-ends are supplied with oil by trough and dipper and, in the other, by pressure from the main bearings through oil-ways drilled in the webs and journals of the crankshaft, whilst on veil, rare occasions both systems are employed together.

Whichever ell system is used, an engine is invariably fitted with an oil pump, filter and sieve (or strainer). The pump is either submerged in the oil sump or is a few Inches above it. The filter is situated on the suction side of the pump, i.e., between sump and pump. The sieve is located in the bottom half of the crankcase above the oil sump.

Considering, first of all, the system where the oil is supplied by pressure to the main bearings and by trough and dipper to the big-end bearings (this is known as the trough-and-dipper oiling system), oil is pumped from the sump through the Biter and into the main oil supply pipe, from which it is distributed to various points all over the engine, a branch pipe being connected direct to the pressure gauge on the dashboard. As this article treats with main and big-end bearings • only, the lubrication of other parts of the engine will not be dealt with. From the main oil pipe a smaller pipe is taken to feed all the main bearings under pressure. Another branch pipe is taken from the main supply pipe to feed the oil troughs into which the big-end dippers pass, and it is in the last-mentioned supply pipe that most of the trouble usually occurs, due to the presence of foreign matter which obstructs the free passage of oil into the • troughs.

The presence of foreign matter in the oil pipes Is invariably due to neglect on the part of those responsible for the machine in not carrying out the makers' instructions. Many authorities on the subject recommend that the engine oil in the sump should be emptied out at the completion of every 1,000 miles' running and replaced by a new and correct quantity of suitable oil of a good brand. It is useless continuously adding new oil to old, as, not only is there a lot of sludge in old and used oil, but its lubricating qualities may become valueless owing to repeated use.

Oil filters should be cleaned and examined daily, preferably in the morning before starting, as then the oil will have drained away from the filter and cleaning will befacilitoted, whilst a certain amount of oil wastage will be prevented. After the filter has been thoroughly cleansed in paraffin, it should be carefully examined to ensure that the gauze is intact and that no punctures o r breaking away at the soldered joints have occured. The oilfilter body should be examined, and any foreign matter, however small, removed. At the same time the Jointing between the body and cover should be examined to ensure a good joint being made when the cover is replaced on the filter body. When replacing the oil filter great care should be taken with the gauze, as it is liable to become buckled, and, further, an oiltight joint must be made between the filter body and cover, as before mentioned. The reason for this great care with the oil filter is obvious. The designer of the engine determines the mesh of the gauze most suited to the engine. Therefore, in the event of larger perforations developing in the gauze, foreign matter will be allowed to pass which would be too large

olli

III 1117(11 //M.

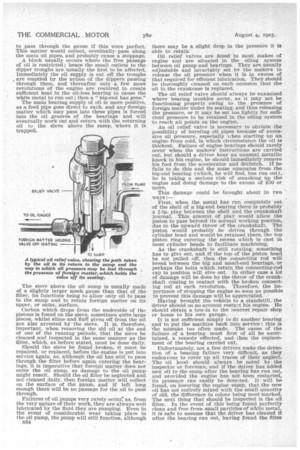

Under working conditions heat • is generated in a bearing and is distributed by radiation and by the heating of the oil, whilst a certain amount is retained in the bearings and their housings. to pass through the gauze if this were perfect. This matter would collect, eventually pass along the main oil pipes, and probably cause a stoppage.

A block usually occurs where the free passage of oil is restricted ; hence the small outlets to the dipper troughs are usually the first to be affected. Immediately the oil supply is cut off the troughs are emptied by the action of the dippers passing through them, and thereafter only a few more revolutions of the engine are required to create sufficient heat In the oil-less bearing to cause the white metal to run out ; then a "big-end has gone."

The main bearing supply of oil is more positive, as a feed pipe goes direct to each, and any foreign matter which may pass into these pipes is forced into the oil grooves of the bearings and will eventually work out and return with the returning oil to the sieve above the sump, where it is trapped.

The sieve above the oil sump is usually made of a slightly larger mesh gauze than that of the filter, its functions being to allow only oil to pass to the sump and to retain foreign matter on Its upper, or outer, surface.

Carbon which drops from the underside of the pistons is found on the sieve, sometimes quite large pieces, whilst slime and fluff given off from the oil are also arrested by the sieve. It is, therefore, important. when removing the old oil at the end of one of the running periods, that the sieve be cleaned and inspected in the same manner as the filter, which, as before stated, must be done daily. Should the sieve be found broken, it must be repaired, or replaced, before the engine is put into service again, as, although the oil has still to pass through the filter before again entering the bearings, it is imperative that foreign matter does not enter the oil sump, as damage to the oil pump might result. Should the oil filter be neglected and not cleaned daily, then foreign matter will collect on the surface of the gauze, and if left long enough there will be no passage for the oil to pass through.

Failures of oil pumps very rarely occur, as, from the very nature of their work, they are always well lubricated by the fluid they are pumping. Even in the event of considerable wear taking place in the oil pump, the pump will still function, although 1334 there may be a slight drop in the pressure it is able to retain.

Oil relief valves are fitted to most makes of engine and are situated in the oiling system between oil pump and bearings. They are usually adjustable and invariably set by the makers to release the oil pressure when it is •in excess of that required for efficient lubrication. They should be thoroughly cleaned on each occasion that the oil in the crankcase is replaced.

The oil relief valve should always be examined where bearing troubles occur, as it may not be functioning properly owing to the presence of foreign matter under its seating, and thus releasing the pressure, or it may be set too lightly for sufficient pressure to be retained in the oiling system to reach all points on the engine.

An oil relief valve is necessary to obviate the possibility of bursting oil pipes because of excessive oil pressure, especially when starting up an engine from cold, in which circumstance the oil is thickest. Failure of engine bearings should rarely occur when the makers' instructions are carried out, but should a driver hear an unusual metallic knock in his engine, he should immediately remove his foot from the accelerator and declutch. If he fails to do this and the noise emanates from the big-end bearing (which, he will find, has run out), he is taking a serious risk of smashing up the engine and doing damage to the extent of £50 or more.

This damage could be brought about In two ways :— • First. when the metal has run completely out of the shell of a big-end bearing there is probably

a play between the shell and the crankshaft journal. This amount of play would allow the piston to pass beyond its normal working position, due to the upward throw of the crankshaft. The piston would probably be driven through the cylinder head and would be retained there, the top piston ring entering the recess which is cast in most cylinder heads to facilitate machining, • As the crankshaft is still rotating, something has to give out, and if the top of the piston head be not pulled off, then the connecting rod will break between the big and small-end bearings, or perhaps the bolts which retain the connecting-rod cap in position will give out. In either case a lot of damage will be done by the throw of the crankshaft coming in contact with the broken connecting rod at each revolution. Therefore, the importance of stopping the engine so soon as possible to prevent this damage will be appreciated.

Having brought the vehicle to a standstill, the driver should on no account restart his engine. He should obtain a tow-in to the nearest repair shop or home to his own garage.

It is not sufficient simply to fit another bearing and to put the machine back into service : this is the mistake too often made. The cause of the failure of a bearing must first of all be ascertained, a remedy effected, and -L-hen the replacement of the bearing carried out.

Unfortunately, not a few drivers make the detection of a bearing failure very difficult, as they endeavour to cover up all traces of their neglect. The oil level should always be noted by the inspector or foreman, and if the driver has added new oil to the sump after the bearing has run out, and provided the engine has not been restarted, its presence can easily be detected. It will be found, on lowering the engine sump, that the new oil has not entirely mixed with the small quantity of old, the difference in colour being most marked. The next thing that should be inspected is the oil filter. In the event of this being found perfectly clean and free from small particles of white metal,, it Is safe to assume that the driver has cleaned it after the bearing ran out, having found the filter

was "made Up," thus restricting the free passage of oil through it, and therefore cutting off the oil supply. Invariably, in an instance of this nature, the filter gauze will be found to be distorted badly, owing to the high pressure of the oil.

It is very unfortunate that one has to write about and point out such deceitful actions, but this sort of thing does occur daily. The owner is ptit to a big expense in having the machine towed in and rendered unserviceable, and the repairer's cost may be heavier than it would be in the ordinary way, for the repairer would spend a lot cf time looking for a cause of failure which did not exist when the machine was banded over to him for repairs. Engines fitted with pressurefed big-end bearings are dependent upon the main bearings for the supply of oil. On a fourcylinder engine, having three main bearings, No. 1 big-end would be fed from the front main bearing, Nos. 2 and 3 big-ends from the middle main bearing, and No. 4 from the rear main bearing.

The chief cause for bearing failures on this type of engine is a _main bearing liner turning in Its housing and thus cutting off the supply of oil, not only to itself, but also to the big-ends, tIO latter usually running out before the main bearing ; although this main bearing would partially run out also.

Main bearings usually turn in their 'housings owing to the absence of a dowel, or the breaking away of one defectively fitted. Stoppages of oil supply to the big-end bearings, due to foreign matter collecting in the oil-ways drilled in the crankshaft, are very rare, because these ways are usually of ample diameter.

All the conditions previously mentioned in the trough-and-dipper type engine obtain in this instance, with the exception of the remarks upon dippers and troughs and the stoppage of oil supply to them. The detachment of a dipper is not a very prevalent cause for a big-end failure. Perhaps it would not be out of place to explain here the action of-the dipper, after which the result of the absence of the dipper will be more clearly understood.

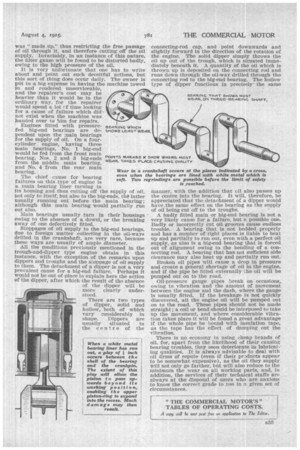

sEARANC WkLCH

sr-lows Le.cisT There are two types of dipper, solid and hollow, both of which vary considerably in shape. Dippers are usually situated in the centre of the connecting-rod cap, and point downwards and slightly forward in the direction of the rotation of the engine. The solid dipper simply throws the oil up out of the trough, which is situated immediately beneath it. A quantity of the oil which is thrown up is deposited on the connecting rod and runs down through the oil-way drilled through the connecting rod to the big-end bearing. The hollow type of dipper functions in precisely the same manner, with the addition that oil also passes up the centre into the bearing. It will, therefore, be appreciated that the detachment of a dipper would have the same effect on the bearing as the supply of oil being cut off to the troughs.

A badly fitted main or big-end bearing is not a very likely cause for a failure, but a possible one. Badly or incorrectly cut cal grooves cause endless trouble. A bearing, that is .not bedded properly and has a number of tight places is liable to heat up and partially to run out, even with a perfect oil supply, as also is a big-end bearing that Is forced out of alignment owing to the bending of a connecting rod. A bearing that has.not sufficient side clearance may also heat up and partially run out.

Broken oil pipes will cause a drop in pressure and create a general shortage of oil in the engine, and if the pipe be fitted externally the -oil will be pumped out on to the road.

Oil-pressure gauge pipes break on occasions,. owing to vibration and the amount of movement between the engine and the dash, where the gauge is usually fitted. If the breakage is not quickly discovered, all the engine oil will be pumped out on to the road. These pipes should not be made straight ; a coil or bend should be interposed to take up the movement, and where considerable vibration takes' place it will be found a great advantage if the whole pipe be bound with insulation tape, as the tape has the effect of damping out the -vibration.

There is no economy in using cheap brands of oil, for, apart from the likelihood of their causing bearing troubles, they soon deteriorate in lubricating qualities. It is always advisable to deal with oil firms of repute (even-if their praducts appear to be somewhat 'expensive), as the oil they supply will not only go farther, but will also reduce to the minimum the wear on all working parts, and, in addition, the services of their technical staffs are always atthe disposal of users who are anxious to know tiie correct grade to use in a given set of circumstances.