The New Model De Dion Engines.

Page 5

Page 6

If you've noticed an error in this article please click here to report it so we can fix it.

The two latest models of four-cylinder engines made by the famous French makers Messrs. De Dion, Bouton et Cie., are the ish.p. and 3oh.p. sizes. The general design of each is on the same lines, and the two engines differ only with regard to their dimensions. The 15h.p, engine has cylinders 90mm. diameter in the bore, with a piston-stroke of mornm., and the 3oh.p. has cylinders nomm. in diameter with a piston-stroke of 130mm.

The leading points of these engines are e Separate water-cooled cylinders.

Mechanically-operated inlet valves on the same side as the exhaust valves.

Crankshaft with five bearings.

Dual ignition, by dry batteries GI accumulators, and by low-tension magneto-generator, with single coil and distributor.

Automatic lubrication under pressure from a gear pump. The cylinders, although cast separately, are arranged in pairs, in order to allow of the induction-pipes' being as short as possible. The cylinders are designed with separate domes to the water-jackets, and a large-diameter hole through the combustion chamber allows reasonably large supports for the cylinder and water-jacket cores, thus ensur

ing perfectly sound castings, perfectly free from flow. The holes in the combustion chamber are closed by means of plugs whose stems are screwed to receive nuts which clamp down the water-jacket domes. The pistons are each fitted with three rings, and the length of each piston is equal to its diameter. The gudgeon-pins are secured in place by tapered screws, as in former models. The pressed-steel " I " section connecting-rods are fitted at the big-ends with long bushes which are prevented from rotating by means of set screws : the big-end caps are located by dowel pins, and each is bolted up by two steel bolts.

The crankshaft bearings are so arranged in the upper part of the crankcase, thm the lower part of the case may be taken down without disturbing the shaft. Steel thrustwashers are introduced, to take the thrust due to the clutch spring. Both inlet and exhaust valves are on the same side of the cylinder, and are operated from the same camshaft. The valves, as well as the screwed plugs, take the same form as those of the single-cylinder engines, and are interchangeable. A pinion on the crankshaft drives the camshaft and magneto through a train of gear wheels. The cams raise the valves through trip levers which are hinged on a shaft parallel with the camshaft ; this shaft may be moved in the direction of its axis, and by this means brings the trip-lever rollers into a position in which they are actuated by the halfcompression cams forming integral parts of the exhaust cams. The Movement of the trip-lever shaft is effected by a lever acting in a flanged collar secured to the shaft, and is returned to normal position by a strong compression spring.

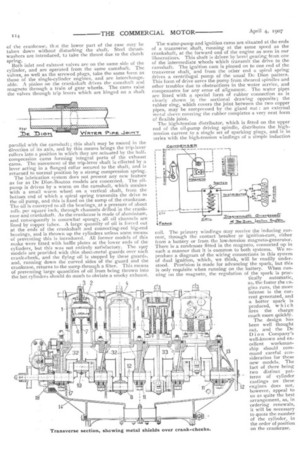

The lubrication system does not present any new feature as far as De Dion-I3outon models are concerned. The oilpump is driven by a worm on the camshaft, which meshes with a small worm wheel on a vertical shaft, from the bottom end of which a spiral spring transmits the drive to the oil pump, and this is fixed on the sump of the crankcase. The oil is conveyed to all the bearings, at a pressure of about Jolb. per square inch, through channels drilled in the crankcase and crankshaft. As the crankcase is made of aluminium, and consequently is somewhat spongy, all oil channels are lined by copper tubes. A large quantity of oil is forced out at the ends of the crankshaft and connecting-rod big-end bearings, and is thrown up the cylinders unless some means of preventing this is introduced. All former models of this make were fitted with baffle plates at the lower ends of the cylinders, but this was not entirely satisfactory. The igo7 models are provided with thin sheet-metal guards over each crank-cheek, and the flying oil is stopped by these guards, and, running down the curved sides of the guard and the crankcase, returns to the sump through a filter. This means of preventing large quantities of oil from being thrown into the hot cylinders should do much to obviate a smoky exhaust. The water-pump and ignition cams are situated at the ends of a transverse shaft, running at the same speed as the crankshaft, at the forward end of the engine as seen in our illustrations. This shaft is driven by bevel gearing from one of the intermediate wheels which transmit the drive to the camshaft. The ignition cam is pinned on to one end of the transverse shaft, and from the other end a spiral spring drives a centrifugal pump of the usual De Dion pattern. This form of drive saves the pump from sheared spindles and other troubles due to obstructions in the water service, and compensates for any error of alignment. The water pipes are fitted with a special form of rubber connection as is clearly shown in the sectional drawing opposite ; the rubber ring, which covers the joint between the two copper pipes, may be compressed by the gland nut : an external metal sleeve covering the rubber completes a very neat form of flexible joint.

The high:tension distributor, which is fitted on the upper end of the oil-pump driving spindle, distributes the hightension current to a single set of sparking plugs, and is in series with the high-tension windings of a simple induction coil. The primary windings may receive the inducing current, through the contact breaker or ignition-cam, either from a battery or from the low-tension magneto-generator. There is a condenser fitted in the magneto, connected up in such a manner that it is common to both systems. We reproduce a diagram of the wiring connections in this system of dual ignition, which, we think, will be readily understood. Provision is made for advancing the spark, but this is only requisite when running on the battery. When running on the magneto, the regulation of the spark is practically automatic, as, the faster the engins runs, the more intense is the current generated, and a hotter spark is produced, which fires the charge much more quickly.

The design has been well thought out, and the De Dion Company's well-known and excellent workmanship should command careful consideration for these new models. The fact of there being two distinct patterns of cylinder castings on these engines does not, however, appeal to us as quite the best arrangement, as, in ordering renewals, it will be necessary to quote the number of the cylinder, in the order of position on the crankcase.