Convertible Tip-trailer/Conveyor

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

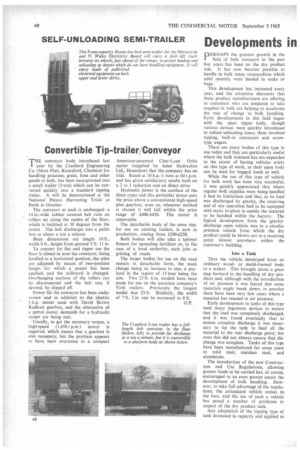

'THE conveyor body introduced last 1 year by the Cranford Engineering Co. (Mere Platt, Knutsford, Cheshire) for handling potatoes, grain, lime and other goods in bulk, has been incorporated into a small trailer (3-ton) which can be converted quickly into a standard tipping trailer. It will be demonstrated at the National Potato Harvesting Trials at Perth in October.

The conveyor as such is unchanged: a 14 in.-wide rubber covered belt runs on rollers set along the centre of the floor, which is inclined at 30 degrees from the centre The belt discharges into a pallet box at about a ton a minute.

Body dimensions are length 10 ft., width 6 ft, height from ground 5 ft. 11 in.

To convert for flat and tipper use the floor is closed in over the conveyor, being levelled to a horizontal position, the sides are adjusted by means of two-position hinges for which a patent has been applied, and the tailboard is changed. Overhanging sections of the rollers can be disconnected and the belt can, if desired, be slipped off.

Power fOr the conveyor has been under review and in addition to the electric I h.p. motor used with David Brown Radicon gearbox, and the alternative of a petrol motor, demands for a hydraulic motor are being met.

Usually, to get the necessary torque, a high-speed (1,450 r.p.m.) motor is required, which means that a gearbox is also necessary, but the problem appears to have been overcome in a compact

American-patented Char-Lynn Orbit motor (supplied by Adan Hydraulics Ltd., Hounslow) that the company has on trial. Rated at 10 h.p. it runs at 60 r.p.m. and has given satisfactory results both on a 2 to 1 reduction and on direct drive.

Hydraulic power is the costliest of the three types and this particular motor puts the price above a conventional high-speed plus gearbox; even so, whatever method is chosen it will fall within the price range of L4004450. The motor is removable.

The detachable body of the same size, for use on existing trailers, is now in production, costing from f200-£250.

Both bodies will also take a spinner fitment for spreading fertilizer or, in the case of a local authority, such jobs as gritting of roads.

The larger bodies for use on the road remain in detachable form, the main change being an increase in size, a payload in the region of 15 tons being the aim. Two 25 ft. 6 in. models have been made for use on the associate company's York trailers. Previously the longest model was 23 ft. Similarly, the width of 7 ft. 2 in. can be increased to 8 ft.