A Breakaway mbul ance Design

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

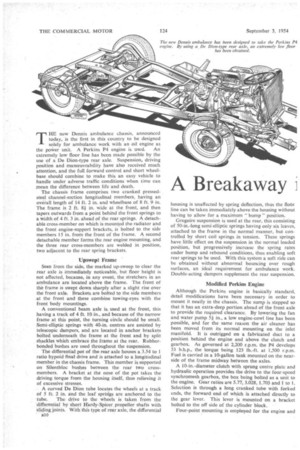

— and a New Underfloor-engined Passenger Chassis, Both from Dennis: Perkins Engine in Ambulance Chassis THE new Dennis ambulance chassis, announced today, is the first in this country to be designed solely for ambulance work with an oil engine as

the power unit. A Perkins P4 engine is used. An extremely low floor line has been made possible by the use of a De Dion-type rear axle. Suspension, driving position and manceuvrability have also received much attention, and the full forward control and short wheelbase should combine to make this an easy vehicle to handle under adverse traffic conditions when time can mean the difference between life and death.

The chassis frame comprises two cranked pressedsteel channel-section longitudinal members, having an overall length of 14 ft. 2 in, and wheelbase of 8 ft. 9 in. The frame is 2 ft. 84 in. wide at the front, and then tapers outwards from a point behind the front springs to a width of 4 ft. 3 in. ahead of the rear springs. A detachable cross-member on which is mounted the radiator and the front engine-support brackets, is bolted to the side members 15 in. from the front of the frame. A second detachable member forms the rear engine mounting, and the three rear cross-members are welded in position, two adjacent to the rear spring brackets.

Upswept Frame ' Seen from the side, the marked up-sweep to clear the rear axle is immediately noticeable, but floor height is not affected, because, in any event, the stretchers in an ambulance are located above the frame. The front of the frame is swept down sharply after a slight rise over the front axle. Brackets are bolted to the side members at the front and these combine towing-eyes with the front body mountings.

A conventional beam axle is, used at the front, this having a track of 4 ft. 10. in., and because of the narrow frame at this point, the turning circle should be small. Semi-elliptic springs with 40-in. centres are assisted by telescopic dampers, and are located in anchor brackets bolted underneath the frame at the front and by split shackles which embrace the frame at the rear. Rubberbonded bushes are used throughout the suspension.

The differential pot of the rear axle houses a 3.54 to 1 ratio hypoid fine drive and is attached to a longitudinal member in the chassis frame. This member is supported on Silentbloc bushes between the rear two crossmembers. A bracket at the nose of the pot takes the driving torque from the housing itself, thus relieving it of excessive stresses.

A curved De Dion tube locates the wheels at a track of 5 ft; 2 in. and the leaf spriiigs are anchored to the

'tube. The drive to the wheels is taken from the differential .by short Hardy-Spicer propeller shafts with sliding joints. With this type of rear axle, the differential i310

housing is unaffected by spring deflection, thus the floor line can be taken immediately above the housing without having to allow for a maximum `, bump " position.

Gregoire suspension is used at the rear, this consisting of 50-in.-long semi-elliptic springs having only six leaves, attached to the frame in the normal manner, but controlled by short coil springs in tension. These springs have little effect on the suspension in the normal loaded position, but progressively increase the spring rates under bump and rebound conditions, thus enabling soft rear springs to be used. With this system a soft ride can be obtained without abnormal bouncing over rough surfaces, an ideal requirement for ambulance work. Double-acting dampers supplement the rear suspension.

Modified Perkins Engine Although the Perkins engine is basically standard, detail modifications have been necessary in order to mount it neatly in the chassis. The sump is stepped so that it has an extra-deep portion ahead of the front axle to provide the required clearance. By lowering the fan and water pump in., a low engine-cowl line has been possible, and for the same reason the air cleaner has been moved from its normal mounting on the inlet manifold. It is outrigged on a fabricated duct to a position behind the engine and above the clutch and gearbox. As governed at 2,200 r.p.m. the P4 develops 53 bh.p., the torque being 123 lb.-ft. at 1,500 r.p.m. Fuel is carried in a Ill-gallon tank mounted on. the nearside of the frame midway between the axles.

A 10-in.-diameter clutch with sprung centre plate and hydraulic operation provides the drive to the four-speed synchromesh gearbox, the box being bolted as a unit to the engine. Gear ratios are 5.77, 3,028, 1.703 and 1 to I. Selection is. through a long cranked tube with forked ends, the forward end of which is attached directly to the gear lever. This lever is mounted on a bracket bolted to the off side of the cylinder block.

Four-point mounting is employed for the engine and

gearbox unit, with Metalastik sandwich rubbers in compression and shear at the front. These are arranged between two V-shaped members, the upper one bolted directly to the engine brackets and the lower one to extension pieces from the front cross-member. The rear mounting employs Metacone units, the linkage to these being similar to those on the Dennis Stork. Instead of being on the clutch housing, the rear mounting brackets are bolted to the rear of the gearbox casing. This has been done to offset the engine 14 in. from the chassis centre line, thereby increasing the space available. for the driver.

Similarly, by mounting the engine well back in the frame, not only is the transmission line shortened, but the driver has access to his seat from each side. Ample clearance is afforded between the front of the cowling over the radiator and the front of the vehicle; A shallow duct leads from the low-set air-intake grille to the pressurized radiator and engine cowl, but this does not cause obstruction to movement between the near-side doorway and the driver's seat. The absence of a radiator in the front of the chassis would enable a body to be constructed with a windscreen within about 3 ft. of ground level.

Braking is by Girling hydraulic gear, with twoleading-shoe units on the front axle. On both axles the brake drums are 12 in. in diameter and 24 in. wide, and the hand brake acts on the rear wheels through a cable and rod linkage.

Pedals and master cylinders for both clutch and brake operation, the accelerator pedal and the steering box are mounted on a tubular bracket outrigged from the off side of the frame, and thus form a complete interchangeable sub-assembly. The two master cylinders are also interchangeable. Burman recirculatory-ball steering gear is used, having a high efficiency rating, and Thompson self-adjusting joints are fitted to drag-link and track-rod ends.

The dash assembly, as supplied with the chassis, is built as a unit around two pressed-steel channels and is mounted on rubber at four points on the frame. It consists of the two box-shaped front wings, on which are mounted the seats, the floor plates, bonnet and cowling, front panel and grille, and the air duct. The bonnet is hinged centrally, the near side opening along the full length of the engine and the off side opening for the rear half only. This is because the gear lever projects through the front of the side cowling nearer to the driver. Two 6-v. batteries with a total capacity of 121 amp.-hours, are located behind the driver's seat.

Disc wheels, with chromium-plated hub caps, carry 7.00-16-in. 8-ply light truck-type tyres. The unladen chassis weight is 1 ton 34 cwt. and with ambulance body and seven passengers and equipment the gross weight is estimated at 2 tons 171 cwt. The body length of 10 ft. 2 in. allows two stretchers or one and seats for five.

Another entirely new Dennis vehicle is a lightweight bus or coach chassis powered by a 54-litre horizontal underfloor oil engine. This unit, which develops 87 b.h.p. gt 2,000 r.p.M., is a development of the Dennis vertical engine of the same capacity. The chassis is of orthodox construction, but provision has been made for a low front or rear entrance by the use of dropped extension members. Forward visibility for the passengers is improved by arranging the driving platform below frame height.

The dropped extension members can be arranged either at the front or rear on the near side, or at the rear on the off side. Gross vehicle weight is just over 9 tons.

A single-dry-plate clutch of 134 in. diameter takes the drive to a five-speed gearbox having constant-mesh gears on third, fourth and fifth speeds. The rear axle has spiral-bevel gears. Two-leading-shoe servo brakes have 16-in. by 3-in, drums at the front and 154-in. by 5-in, drums at the rear.

The 10-stud wheels carry 9.00 by 20-in. 10-ply tyres. The wheelbase is 16 ft. 4 in.