BEDFORD VAN SETS NEW CLASS RECORD

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

T1-11S week 'The Commercial Motor" is able to give an exclusive description and road test of the Bedford P.C.V. 10-12-cwt. delivery van. Based on the popular .1C-type chassis, the new van incorporates a synchromesh gearbox and steering-column change-speed-lever which is now standardized on the new range of Vauxhall cars.

Although fitted with a similar engine to its predecessor and employing the same transmission ratios, much may be said for the higher efficiency of the engine carburation when comparing results with tests made with the earlier model before the war. The results of our test constitute a record for vehicles coming in this class, and generally the whole performance of the van was commendable.

It is powered by the Vauxhall 12 h.p. four-cylindered overheadvalve engine and equipped with the six-phase carburetter. Crankcase and cylinder block are an integral casting in alloy cast iron, housing the counterbalanced crankshaft, which revolves in white-metal-lined bearings. A high-pressure lubrication system is employed, embodying a submerged gear-type pump, which_ is driven in tandem with the distributor from the camshaft front spiralgear. A warning signal on the ihstrument panel lights up when the oil pressure falls below 8-10 lb. per sq. in. Oil filtration is by means of a by-pass filter fed with oil under pressure on a by-pass circuit.

The Zenith 30 V1G-5 model downdraught carburetter is equipped with an accelerator pump and a partthrottle economy valve. Easy starting from cold is ensured by the interconnection of throttle and choke contiols, the choke butterfly being designed to prevent excessive richness of mixture.. An A.C. combined air filter, silencer and flame arrester uses oil-damped wool as the filtering medium.

Engine, clutch and gearbox form an integral unit flexibly mounted at three points, one on each side at the fore-end of the engine, the third, consisting of two thick insulator assemblies, being fitted vertically under the gearbox rear cover. The new gearbox has been designed to transmit the torque of a 2.1-litre engine, therefore, as fitted to the van, it should have a comparatively long life before requiring attention.

It has. the Vauxhall-controlled synchromesh on top and second speeds, and it is not possible to clash the gears, no matter how quickly or slowly the gear change is effected. All gears are helically cut for silent operation. A feature of the gearbox design is the extended rear cover which permits the fitting of a short and stiff propeller shaft, ensuring a smooth and vibrationless transfer of power.

The new gear-selector control. attached to the steering-column tube, is located immediately below the rim of the steering wheel. This control has been designed to give a positive handling quality, free from sponginess and uncertainties. The

selector jaws are positioned at the base of the steering column, and from them two separate push-pull rods run to swinging arms on the side of the gearbox. The layout of the rods and intermediate relay levers leaves the mechanism unaffected by engine movement.

An open propeller shaft. with Hardy Spicer needle-roller bearings, conveys the transmission to the semi-floating rear axle, the torque being taken through the springs. The spiral-bevel gears and differential assembly are mounted in a carrier of malleable-cast iron, which is bolted to the front face of the axle housing.

The rear suspension is through semi elliptic underslung springs, assisted by double-acting hydraulic end-to-end-discharge pattern shock absorbers. At the front axle, each wheel is independently mounted on a carrier arm which is in one piece with the stub axle and rocker shaft. Keyed inside the rocker shaft, a torsion bar and tube assembly carry the load elastically and replace the conventional spring. The action of the torsion members is modified by a stiff coil spring and toggle mechanism, which enables the suspension to stiffen progressively as wheel movement increases. This system has already gained a good record.

A Lockheed cylinder of larger diameter than hitherto is now being used at the front wheels, this being a measure of standardization with the new range of cars. The brake master-cylinder is formed integrally with the brake-fluid reservoir. To improve access to the driving seat, the hand brake is inverted and hangs from the scuttle. Both front and rear brake-drums are cast in one piece with their respective wheel hubs, and are ribbed for rigidity and heat dissipation

Other improvements, which have been incorporated over the 1946-7 JC model include a 12-volt positive earth-return electrical system, balanced direct-lift windows in the two front doors, and modifications to the door-locking mechanism. Modifications have also been made to the head• lamps.

Normally, the van is supplied with a driver's 'seat only, the 10 cubic ft. of space by his side representing additional body space, but the manufacturer thoughtfully provided a second seat in the cab for the observer during our test. From the

weight table of the data panel, it will be seen that ballast load carried was 9 cwt.; this should be extended to 11-cwt. payload to compensate for the weight of the observer and seat, which are additional to the normal driving-cab loading and fittings. This has been corrected in calculating payload ton-m.p.g and ratio between payload gross load.

I noticed that in the load distribution, the lion's share of the weight is taken by the rear axle. Although within the recommended tyre loading, care should be taken to maintain the rear tyre pressures at 36 lb. per sq. in. if a 10-12-cwt. payload is to be habitually carried. While on the

weighbridge, the Tapley gradient meter was fitted and set for the day.

Although started from cold, the engine ran smoothly and did not hesitate once in the short journeys round the works This is particularly good when considering the van already had over 26,000 miles to its credit. As far as the road test is concerned, it is a good feature to have a model which is well bedded down to an operating condition.

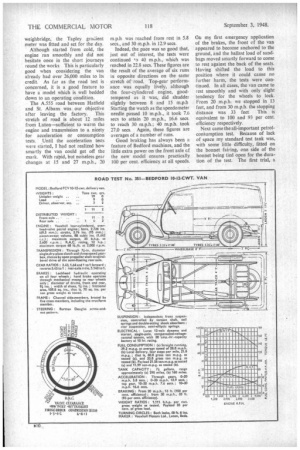

The A.555 road between Hatfield and St. Albans was our objective after leaving the factory. This stretch of road is about 12 miles from Luton—sufficient to warm the engine and transmission to a nicety for acceleration or consumption tests. .Until the acceleration tests were started, I had not realized how smartly the van could get off the mark. With rapid, but noiseless gear changes at 15 and 27 m.p.h., 20 m.p.h was reached from rest in 5.8 secs., and 30 m.p.h. in 12.9 secs,

Indeed, the pace was so good that, just out of interest, the tests were continued to 40 m.p.h., which was reached in 22.8 secs. These figures are the result of the average of six runs in opposite directions on the same stretch ofroad. Top-gear performance was equally lively, although the four-cylindered engine, goodtempered as it was, did shudder slightly between 8 and 15 m.p.h Starting the watch as the speedometer needle passed 10 m.p.h., it took 7.6 secs to attain 20 m.p.h., 16,6 secs. to reach 30 m.p.h.; 40 m.p.h. took 27.0 secs. Again, these figures are averages of a number of runs.

Good braking has always been a feature of Bedford machines, and the little extra power on the front axle cf the new model ensures practically 100 per cent. efficiency at all speeds. 011 my first emergency application of the brakes, the front cf the van appeared to become anchored to the ground, and the ballast load of sandbags moved smartly forward to come to rest against the back of the seats. Having shifted the load to this position where it could cause no further harm, the tests were continued. In all cases, the van came to rest smoothly and with only slight tendency for the wheels to lock. From 20 m.p.h. we stopped in 13 feet, and from 30 m.p.h, the stopping distance was 33 feet. This is equivalent to 100 and 93 per cent. efficiency respectively.

Next came the all-important petrolconsumption test. Because of lack of space my standard test tank was, with some little difficulty, fitted on the bonnet fairing, one side of the bonnet being tied open for the duration of the test. The first trial, a non-stop run, was made over a 12mile give-and-take course observing a maximum speed of 30 m.p.h. This steady running was ideally suited to the Bedford's carburation, and I could see from the quantity used after 6 miles that a record low consumption figure was in the making. Towards the end of the course, we climbed Welwyn Hill, but there was so much reserve engine power that, with slightly more depression of the throttle pedal, the hill was climbed in top gear.

Having measured the distance of the course to a fraction of a mile, fuel was measured into the test tank with equal care. The total consumed for the 12 miles was 0.306 gallons. which is equivalent to 39.2 m.p.g. It took precisely 25 mins. to cover the course, which corresponds to an average speed of 28.8 m.p.h.

A second run, representing local delivery conditions of four stops per mile, was made over the same course. The engine was left idling for 15 secs. at each of the 48 halts and, to make conditions as stringent as possible, the van was braked fiercely at each stop and accelerated sharply away from rest. Even this harsh treatment, which made full use of the carburetter acceleration pump, failed to disprove the economy of the van. At the end of this test, consumption was again carefully measured, r.nd the result of 21.8 m.p.g. recorded. After deducting the 12 minutes standing time, the average running speed for the route was 21.3 m.p.h.

With the large engine fitted to this van, hills present no difficulty, and OfIley Hill, the steepest gradient in the area, was taken in fine style. Stopping and starting on the 1 in 8 section was accomplished, using low speed without abuse to the clutch. With an atmospheric temperature of 52 .degrees F. the radiator top-tank showed 135 degrees F at the foot of the hill and 144 degrees F. at the top.

This, however, cannot be regarded as the operating temperature of the engine because the thermostat fitted in the top-tank cantrols the water temperature in the engine. This is a good feature for a local delivery van, where it is required that the engine should be raised to an operating temperature quickly.

I have always admired the fit and finish of the Bedford door, window and panel pressings. Their accuracy for fit was put to a test when running through a torrential rainstorm; there was no trace of a water leak in the cab or body