Safety on

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

oard

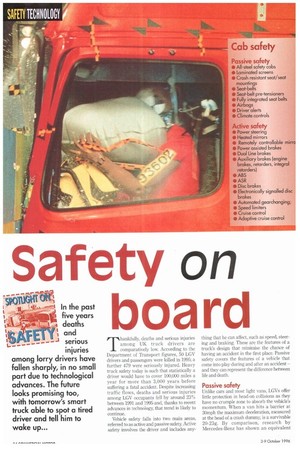

Thankfully, deaths and serious injuries among UK truck drivers are comparatively low. According to the Department of Transport figures, 50 LGV drivers and passengers were killed in 1995; a further 479 were seriously injured. Heavy truck safety today is such that statistically a driver would have to cover 100,000 miles a year for more than 3,000 years before suffering a fatal accident. Despite increasing traffic flows, deaths and serious injuries among LGV occupants fell by around 23% between 1991 and 1995 and, thanks to recent advances in technology, that trend is likely to continue.

Vehicle safety falls into two main areas, referred to as active and passive safety. Active safety involves the driver and includes any

thing that he can affect, such as speed, steering and braking. These are the features of a truck's design that minimise the chance of having an accident in the first place. Passive safety covers the features of a vehicle that come into play during and after an accident — and they can represent the difference between life and death.

Passive safety

Unlike cars and most light vans, LGVs offer little protection in head-on collisions as they have no crumple zone to absorb the vehicle's momentum. When a van hits a barrier at 30mph the maximum deceleration, measured at the head of a crash dummy, is a survivable 20-23g. By comparison, research by Mercedes-Benz has shown an equivalent figure for a flat fronted truck can reach 90g, which is way above the normal survival level.

Put bluntly, Mercedes-Benz says it is impossible to design a conventional truck in which the driver could expect to survive a barrierstyle test of more than 15km/h (9.3mph).

Modern CAD analysis has allowed cab designers to build in strength where it is most needed. For example, Renault's new Premium truck has a bonded windscreen as the engineers found it added valuable strength. The new Mercedes-Benz Actros has a floor assembly and seat mountings designed to absorb forces of up to 95g. The Actros doors are also designed to maximise longitudinal buckling strength in a typical head-to-tail crash.

With the Gib having such a limited effect in reducing the impact of a crash, the seat belt plays an important safety role. Volvo research shows that one in eight unbelted drivers are thrown from their cabs in an accident: it introduced seat belts as long ago as 1979.

However, many drivers still baulk at wearing them, even in the UK, where it is a requirement to do so if they are fitted.

Truck seatbelts can be uncomfortable, particularly when used with suspension seats, but new vehicles such as Scania's 4-Series, Renault's Premium and M-B's Actros feature belts which are integral with the seat frame, making them much more user friendly. The 4Series and the Actros also offer seat belt pre tensioners which take up to 100mm of slack in the belt in the event of a crash, restraining the driver more effectively to further minimise injury.

In 1995 Volvo became the first truck manufacturer to fit airbags: they are now available in its Fl-1 range, as well as the 4-Series and the Actros. An airbag can help reduce injuries to eyes, nose and teeth, but is of secondary importance to the seat belt and does not help at all if the driver is not strapped in.

Active safety systems cannot help a driver avoid a crash if he is too tired to concentrate, but the boundary between passive and active safety is becoming blurred; systems such as the Vigilence being researched by Renault are designed to detect the onset of fatigue and sound a warning.

In the case of the Vigilence system an infrared camera films the driver's face and his eyelid movements are analysed and compared with a pre-determined vigilance level. If his awareness is low a synthesised voice warns him and the system turns on the radio and/or air conditioning. It can even slow the vehicle down after an appropriate warning.

Scania's Driver Alert system is not as sophisticated but it's already available: it generates random sounds which sleepy drivers find hard to ignore.

Active safety

Because of the difficulty in building an acceptable level of passive safety into LG Vs, most of the major advances have come under the heading of active safety. Brake technology is a good example, with advances such as power assistance in the fifties, dual circuits, automatic slack adjusters and spring parking brakes in the sixties, load sensing valves in the seventies and anti-lock brakes in the eighties.

The nineties have brought a number of improved engine brakes and integral hydraulic retarders which have improved the safety of top-weight trucks by saving wear on the service brakes. Scania, for example, says its integral retarder reduces the use of the service brakes by up to 80% while allowing downhill running at constant speed with no risk of fade.

Anti-lock brakes are now common: thanks to electronics the latest systems can be equipped with traction control at little if any extra cost.

Disc brakes are lighter and cheaper to maintain than drums; they have been used on front axles for some time and the latest models from Scania and Mercedes-Benz feature disc brakes all round, controlled electronically rather than by air pressure. A conventional braking system takes around 0.6sec to reach maximum operating pressure after the driver's foot hits the brake pedal -this delay is halved by using electronic signalling. At 80km/h that 0.3sec equates to 16.7m, which could easily be the difference between a near miss and a collision.

In the future engineers should be able to reduce the stopping distance further by using the full potential of the discs themselves, but the big advances will need a change in the braking regulations.

In the meantime Renault has put much development into a carbon-carbon disc material called Sepcarb which is a quarter of the weight of steel and actually gets tougher as the temperature increases beyond 2,0000 C. In theory, an electronically signalled, disc-braked vehicle with ABS could stop as quickly and as safely as a medium van.

Speed limiters and cruise control have become extremely refined with advances in electronic engine control; we can look forward to "intelligent" systems that think for the driver and improve safety still further. MAN has already demonstrated its Adaptive Cruise Control (ACC), which is able to reduce the vehicle speed in order to maintain a safe stopping distance from a vehicle ahead of it. ACC has been demonstrated on a coach using a Telma retarder but could easily be adapted to trucks once electronically managed engines become the norm.

I— by Gibb Grace