Revolutio Trail€

Page 102

Page 103

Page 104

If you've noticed an error in this article please click here to report it so we can fix it.

Lithe

ndustry

Air Suspension to the Fore in Trailers and Semi-trailers : Disc Brakes Shown by: One Manufacturer : Improved Automatic couplings

By Anthony Ellis

-1vNTITI-I a few notable exceptions, such as the Crane trailing-arm bogie and the British Trailer Company's Four-in-line layout, design of both trailer and semi-trailer chassis frames and running gear had, until about 12 months ago, almost stood still for 20 years. During this period there had, of course, been a multitude of detail modifications, but the basic twoor four-leaf-spring bogie had reigned supreme.

Now radical changes are occurring in the trailer industry, mainly because of the rapid acceptance of air suspension since the component parts for this equipment became readily available in this country.

The new method of suspension has several advantages to offer to trailer manufacturers. Probably the most important of these is that because of its constant

periodicity characteristics, an air-sprung trailer is equally well suspended whether laden or unladen, Thus, the air-sprung trailer will not tend to jar itself to destruction when towed at high speed unladen.

Even though the tandem-axle airsuspehded bogies offered at the moment may add £200 or more to the cost of a 15-ton semi-trailer, it is money well spent if maintenance of both the bodywork and running gear is reduced. When the body is a £3,000 tank the additional cost is negligible if the tank life is doubled, as some authorities suggest.

For both vehicles and their trailers the cry is for increased payloads and with present legislation in this country this can be achieved only by a reduction in unladen weight. Up to 10 cwt. can be saved on a tandem-axle bogie when four leaf springs are replaced by two air pillows, this being a further justification for the increased initial cost of air springing.

Dyson were the first to offer an airsprung semi-trailer in this country last year. Since that time they have sold more than 50 vehicles incorporating their Aeroride suspension. This simple tandemaxle layout employing two 66-in.-long air pillows mounted above surge tanks to which the axles are clamped is shown as part of a 15-17-ton platform semitrailer on stand 101.

Another pioneer development on this model is the use of Girling singlecalliper disc brakes on all wheels. The brakes are operated by direct air pressure through a single diaphragm air cylinder, situated at the centre of each axle, with a mechanical linkage to the operating levers for the callipers. The hand brake operates on the discs of the forward axle through the same linkage.

The only air-sprung four-wheeled trailer in the Show is also exhibited by Dyson. This has Dunlop two-convolution air bellows as the suspension medium for each axle. Trailing radius arms with rubber-bushed forward mountings locate the axle and telescopic shock absorbers are fitted at the end of each arm.

Total deflection of the suspension is about 3 in., this being controlled by rebound rods with rubber snubbers. A levelling valve is fitted at each side of the rear axle, with a similar unit in the centre of the front axle.

This 8-ton trailer also employs calliper disc brakes, in this case of Dunlop manufacture, operated hydraulically with airpressure assistance. The hand brake actuates a separate set of callipers on the rear-axle discs through a mechanical linkage.

Whereas Dyson, Eagle and York each use a single two-convolution air pillow at each side of the bogie in a similar layout, Carrimore Six-Wheelers, Ltd. employ four 29-in.-long pillows for their air suspension (Stand 120). This dispenses with the need for a surge tank, because air can pass freely between the two pillows on each side as the axles move relatively to

each other. Axle location is by eight leading-and-trailing radius arms and two Panhard rods, all these linkages being rubber-bushed to eliminate maintenance.

On Stand 106, Cranes (Dereharn), Ltd.. show their Airtrail air-sprung bogie. This is the most original design of any exhibited. Four stub axles are carried on box-section trailing arms with two Firestone Airide two-convolution air bellows mounted on extensions of the rear trailing arms, abutting at their upper ends • on the forward arms. Thus one air bellows unit suffices for the tandem wheels on each side of the bogie, damping being by two mid-mountedtelescopic shack absorbers.

Bellows and canister air springs have an advantage over the pillow design: Not only .do they take .up less space, but their shape makes it possible to mount them behind the rear wheels • and, if required, they can be outrigged from the chassis frame to give a wide spring base and thus minimize roll. Pillows, on the other hand, must normally be mounted in the position otherwise taken by conventional leaf springs.

Outrigged bellows are used on a 2,100-gal. semi-trailer exhibited by Thompson Bros. (Bilston), Ltd,, on Stand 107. The running gear is made up of a single axle carried on trailing radius arms which are box-section members drilled for lightness. Pivoting in rubber bushes at their forward ends, the arms are joined. at the rear by a channel section cross member which forms a tray to carry the suspension units

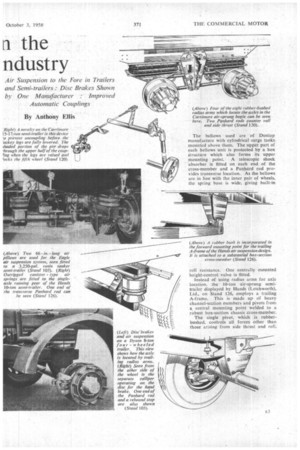

The bellows used are of Dunlop manufacture with cylindrical surge tanks mounted above them. The upper part of each bellows unit is protected by a box structure which also forms its upper mounting point. A telescopic shock absorber is fitted on each end of the cross-member and a Panhard rod provides transverse location. As the bellows are in line with the inner pair of wheels, the spring base is wide, giving built-in roll resistance. One centrally mounted height-control valve is fitted.

Instead of using radius arms for axle location, the 10-ton air-sprung semitrailer displayed by Hands (Letchworth), Ltd., on Stand 126, employs a trailing A-frame. This is made up of heavy channel-section members and pivots from a central mounting point welded to a robust box-section chassis cross-member.

The single pivot, which is rubberbushed, controls all forces other than those arising from side thrust and roll, these being contained by a transverse Panhard rod at the rear of the frame. The two metal-gaitered canister-type air springs are outrigged behind the wheels on a cross-member at the rear of the A-frame and abut at their upper ends on a top-hat-section cross-member. Two telescopic shock absorbers and two height-control and levelling valves are fitted on each side of the axle.

Rubber-bushed linkages are now. almost standard practice for trailer design, having an obvious advantage in reducing maintenance. Thus, the 16-18-ton semitrailer chassis shown by Hands with all rubber suspension is of great interest. The tandem-axle • bogie is a Hendrickson design and employs four rubber cushions as the suspenSion medium.

Two walking beams are used, the ends of them being pivoted on the bottom of the axles. Leading-andtrailing radius arms run from a central chassis cross-member to brackets on top of each axle. The bogie is said to have fine riding characteristics and allows good articulation. It probably requires even less maintenance than air-suspension designs and has the advantage of being self-contained and not dependent on a separate unit for an air supply.

Unique at present in this country is the 15-ton side-by-side twin-axled semitrailer with air suspension on Stand 104Taskers of Andover (1932). Ltd. Each of the axles is carried on a trailing tubular beam which is extended rearwards to carry canister-type air springs and twin telescopic shock absorbers. Each beam is. located at its forward end by a T-piece mounted in rubber-bushed brackets.

This trailer is interesting also in being the only one in the Show fitted with the Bendix-Westinghouse • electro-pneumatic tractor-trailer braking system. This apparatus reduces delay in applying the semi-trailer brakes, and allows a greater degree of braking synchronization between the two units of the outfit than has hitherto been possible.

Yet another novelty 'in Taskers' display is their P.V. rear-steering semi-trailer. This also has twin side-by-side axles, the supports for each axle being mounted on a ball-bearing turntable with a track rod connecting the two turntables. A spring-loaded wedge fitted to the upper half of the fifth-wheel coupling engages with the V-shaped slot in the fifth wheel itself and is turned by angular changes between the tractor and semi-trailer.

Movement of the wedge is transferred by linkages to a steering arm on top of the near-side turntable, thus steering the trailer wheels. The geometry of this layout is such that almost perfect tracking by the semi-trailer wheels is achieved in all manceuvres which can be carried out at normal speeds. The unit does not cut corners and is thought to have many applications for operation in confined spaces.

Articulated buses are uncommon an( such vehicles with air suspension art even rarer. Thus the 60-seat articulate( bus shown in the demonstration park by the British Trailer Co., Ltd., is of grew interest.

The single axle of the semi-trailer it carried on trailing radius arms which art extended rearwards and joined behinc the wheels by a cross-member on which two triple-convolution air bellows art mounted. A delay-type levelling valve is fitted beside each bellows and two telescopic shock absorbers are used.

On Stand 112 the British -Trailer Co. show a typical trailer axle fitted with Dunlop disc brakes.

A revival of interest in automatic interchangeable couplings 'appears to be taking place. All the larger manufacturers of this type of equipment are showing recently introduced modified versions of their gear.

Scammell Lorries, Ltd., Tolpits Lane,

Watford, were the first to produce a coupling of this type and now offer a Mark II gear for four-wheeled tractors. Examples of this coupling may be seen in the demonstration park.

Hands have their 0-type coupling on display. It is rated for 12-ton semitrailers and permits the use of tyres up to 9M020 in. on the rear wheels of the tractor unit.

The Taskers D.-S. coupling, which may be inspected on their stand in a full-scale working demonstration, is notable for positive clamping of t h e semi-trailer forecarriage and the safety features that it incorporates. It is shown fitted to a B.M.C. tractor unit.

On Stand 68, J. Brockhouse and Co., Ltd., 25 Hanover -Square, London, W.1, show their new Mark IV coupling which, by using a Hydrovac to actuate the semi-trailer brakes, gives minimum delay in the braking system and has produced excellent braking figures on test (The Commercial Motor, September 5).