Converted Chassis—

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Economic Coal Haulage

by P. A. C. Brockington,

REDUCING unladen weight to a minimum, using a suitable chassis frame, accurate alignment of tippinggear mechanism and correct weight distribution are considered essential to economic coal transport by A. Fletcher and Co., Ltd., Ibstock, Leicester. In accordance with these principles, most of their vehicles are fitted with all-aluminium tipping bodies produced in the company's Workshops and the vehicles used are, in the main, based on Sentinel chassis, converted by Transport Vehicles (Warrington), Ltd. Particular attention is given to installation of the tipping gears. It is relevant that drivers receive strict

instructions to avoid tipping on site with the vehicle standing on uneven ground.

The concern is one of three in a group of companies which includes Coal Deliveries (East Midlands) Co., Ltd., of Mansfield, and R. E. Mason Transport Co., Ltd., Kilsby, near Rugby. Long-distance coal deliveries, as well as local work, are undertaken by the three companies and the same vehicle policy is generally applicable.

c14

In the case of the Fletcher company, the fli comprises 20 vehicles; and in the main the coll■ tion-and-delivery service offered covers an at extending from Bolton in Lancashire to Land and southern counties. Whilst routine rnaintenar and some overhauls are performed in the woi shop of.each company individually, the rep; facilities of the Mayfair Garage, in Fazeley, m Tamworth (a member of the group) are availal if needed.

In the opinion of Mr. R. Johnston, managi director of the Fletcher company, the frame a typical multiwheel chassis is either too we or too robust for coal--tipper applications (reinfol ..ing with flitch plates is not favoured) and 1 Wheelbase is too long or too short for good weig

distribution. Given that the construction of t body and sub-frame and the layout of the tippir gear matches the construction of a suitable chas it is considered, however, that valuable weig reductions can be made without impairing the ti ping characteristics of the vehicle. In recent ye improvements in loading facilities at coal mix have enabled tippers with higher sides to employed, and vehicles have been modified exploit this advantage in the interests of undo] weight distribution.

Representing the largest number of one type vehicle, five T.V.W.-converted Sentinel six-wheel tippers are normal-control vehicles of 15-ft. whe base equipped with Leyland 0.350 oil engines place of the Sentinel underfloor units, and povs is transmitted through an Albion six-speed-gearb Lo the Kirkstall single-drive axle of the original bogie.

Unladen weight of the vehicle (with a light-alloy body) around 6 tons 8 cwt., and when laden the driving a.] supports 54 per cent, of the total bogie load. Three of 1 chassis are fitted with an Eaton 18500 two-speed as which increases the maximum speed potential of the vehi from 48 m.p.h. to 65 m.p.h.

All T.V.W. vehicles are supplied with a Bowyer Br( plastics cab mounted on a light-alloy framework, the fi of which has been in service since March, 1959. Featu include a floor frame of steel, a roof reinforced w nded-in plastics members and glass-fibre mudguards. Tording an appreciable saving in weight, the cabs have tisfactorily withstood particularly arduous service.

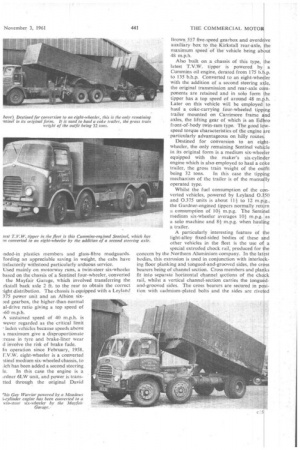

Used mainly on motorway runs, a twin-steer six-wheeler based on the chassis of a Sentinel four-wheeler, converted the Mayfair Garage, which involved transferring the rkstall back axle 2 ft. to the rear to obtain the correct ight distribution. The chassis is equipped with a Leyland 375 power unit and an Albion six.:ed gearbox, the higher-than-normal al-drive ratio giving a top speed of -60 m.p.h.

A sustained speed of 40 m.p.h. is wever regarded as the critical limit laden vehicles because speeds above s maximum give a disproportionate ;rease in tyre and brake-liner wear d involve the risk of brake fade.

ln operation since February, 1958, F.V.W. eight-wheeler is a converted rtinel medium six-wheeled chassis, to ich has been added a second steering le. In this case the engine is a irdner 6LW unit, and power is transtted through the original David 13rown 55,7 five-speed gearbox and overd 've auxiliary box to the Kirkstall rear-axle, he maximum speed of the' vehicle being ab ut 48 m.p.h.

Also built on a chassis of this type, he latest T.V.W. tipper is powered by a Cummins oil engine, derated from 175 b. .p. to 135 b.h.p. Converted to an eight-whe ler with the addition of a second steering a e, the original transmission and rear-axle c ponents are retained and in solo form he tipper has a top speed of around 48 m. .h. Later on this vehicle will be employed to haul a coke-carrying four-wheeled tipp ng trailer mounted on Carrirnore frame nd axles, the lifting gear of which is an Ed ro front-of-body twin-ram type. The good 1 speed torque characteristics of the engine re particularly advantageous on hilly routes Destined for conversion to an ei twheeler, the only remaining Sentinel vehi le in its original form is a medium six-whe er equipped with the maker's six-cylin er engine which is also employed to haul a coke trailer, the gross train weight of the ou t being 32 tons. In this case the tipp ng mechanism of the trailer is of the manu lly operated type.

Whilst the fuel consumption of the c nverted vehicles, powered by Leyland 0. 50 and 0.375 units is about 111 to 12 m.p g., the Gardner-engined tippers normally ret rn a consumption of 10+ m.p.g. The Senti el medium six-wheeler averages 104m.p.g. as a solo machine and 81 m.p.g. when haul g a trailer.

A particularly interesting feature of he light-alloy fixed-sided bodies of these a d other vehicles in the fleet is the use ou a special extruded chock rail, produced for e concern by the Northern Aluminium company. In the lat st bodies, this extrusion is used in conjunction with interlo king floor planking and tongued-and-grooved sides, the cross bearers being of channel section. Cross members and pla ks fit into separate horizontal channel sections of the ch a k rail, whilst a vertical channel-section carries the tongu and-grooved sides. The cross bearers are secured in p sttion with cadmium-plated bolts and the sides are rive ed

with Tucker and Eyelets pop rivets. Four rivets are

employed at each joint of the side sections for attachment to the chock rail, two on the inside and two on the outside. The capping rail is of channel section with a lip extension On the inside, the lip being added to increase the stiffness of the rail.

Although the form of construction employed was evolved to provide adequate torsional strength and to withstand "belling" of the load, the body provides a weight saving (in conjunction with a steel sub-frame with a single crossmember) of 15 to 20 cwt. as fitted to the sixand eightwheelers, compared with a steel body. The body of the eight-wheeler has an approximate length externally of 20 ft. and a width of 8 ft., whilst the height of the sides is 4 ft. 9 in., the bodies of the six-wheelers having a slightly reduced length. Unladen weight of the six-wheelers equipped with Leyland 0.350 engines is approximately 6 tons 8 cwt. and the twin-steer six-wheeler, powered by the Leyland 0.375 unit, has a tare weight of about 5 tons 13 cwt.

Other tippers in the fleet include two Guy Warriors fitted with Meadows four-cylinder engines, which were converted by the Mayfair Garage to twin-steer six-wheelers and also have an unladen weight of around 5 tons 13 cwt. Standard tipping vehicles include two Guy Invincible eight

wheelers fitted with Gardner 6LX engines and ZF six-spei gearboxes, the unladen weight of which is 8 tons 18 cwt.

One of these is equipped with a Neville light-alli U-shaped sectioned body, mounted on a steel sub-f rana particular advantage of the shape being that the radius corners obviate sticking of the material and thus provi easier discharge. A number of these bodies is employ by the Mason company for the transport of cement f which they are particularly suitable because of t " clinging " property of the material. The bodies are cl. externally with aluminium sheet to prevent adhesion of t material to the ribbed sides.

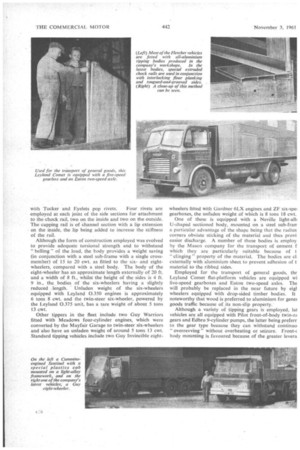

Employed for the transport of general goods, thr Leyland Comet flat-platform vehicles are equipped wi five-speed gearboxes and Eaton two-speed axles. The will probably be replaced in the near future by eigl wheelers equipped with drop-sided timber bodies. It noteworthy that wood is preferred to aluminium for genei goods traffic because of ,its non-slip property: Although a variety of tipping gears is employed, lat vehicles are all equipped with Pilot front-of-body twin-ra gears and Edbro 9-cylinder pumps, the latter being preferr to the gear type because they can withstand continuo overrevving" without overheating or seizure. Frontbody mounting is favoured because of the greater levera

Dbtained and because the open position of the rams facilitates repair when the body is fully laden. Apart from the z.41) wings, the mudguards are attached to the body subframe so that they do not obstruct repair of the chassis when the body is lifted.

Stabiliers are not considered necessary, given accurate fitting of the sub-frame, hinge pins and lifting gears, and, is already mentioned, only one cross member is fitted (at :he front) to the sub-frame. The lifting operation is regularly tested to verify that no differential stressing has been introAwed by excessive strain of the body structure or rams. It is emphasized that loosening of the body or distortion of the assembly will inevitably result in uneven ram action and this would obviously lead to further distortion of the body structure.

Although sufficient traction is provided by the si gledrive axles for normal operations, any simple mean of increasing traction is exploited. Michelin tyres. have 'een found to improve tracffon by an appreciable margin and for this reason they are employed throughout the eel. Their mileage life is satisfactory.

As a footnote, it is pertinent to mention that a Sen inel six-wheeler awaiting conversion has covered over 700.000 miles with the original Fletcher light-alloy body. The I' test aluminium bodies should possess even more favour ble wearing properties.