OLYMPIA'S MOST UNORTHODOX EXHIBIT

Page 108

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

THE unconventionality of design of the Gilford front-drive oilengined passenger vehicle, which was briefly described in our issue dated October 20th, as contrasted with its simplicity to those who have seen it and understand it, creates a difficulty in conveying to our readers a full explanation of the new product without puzzling them with apparent complications.

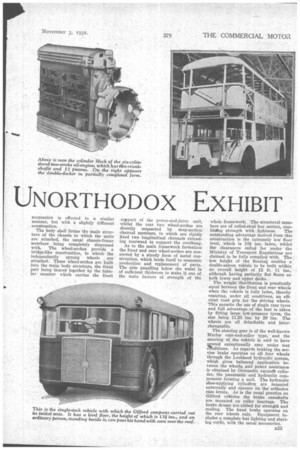

The fundamental features are a sixcylindered compression-ignition engine complete with gearbox, differential unit and final-drive assembly, front-wheel drive, four separately sprung wheels and unit construction of chassis and body frame.

Considering first the engine, the six cylinders have each a bore of 70 mm., and are of the double-piston type, the combined stroke of the two opposed pistons in each cylinder being 210 mm. The engine develops 120 b.h.p. at 2,000 r.p.m. Being of the two-stroke variety it has no valves. It is not an untried product, being the outcome of many years of experience, and arrangements are being made for its manufacture in this country.

The gearbox is located in front of the engine, but is separated from it by the casing containing the differential and worm-drive assembly ; all these components form a complete unit. It might be mentioned here that the gearbox can be separately withdrawn from the unit; this is most important from the point

of view of maintenance. ,

The drive from the engine is taken through a double-plate dutch with divided central driving plate to provide air-cooling. The clutch shaft extends through a hollow worm shaft forward to the gearbox. The drive passes either through the intermediate gears or, by means of a sliding dog, direct from the internal clutch shaft to the splined end

1322 of the tubular worm shaft around it the two then revolving as one.

Special mention should be made of the gearbox, which is of remarkable design. There are four forward speeds, provided through three trains of con stantly meshed gears. Each gear is individually mounted on ball bearings, thus eliminating deflection stresses on the shafts, which are often a source of noise and wear. All the gearwheels are ground, the tooth width of each wheel being 11 in. The teeth are long, the formation being such as to give the maximum number of teeth in contact.

The transmission from the large worm wheel (which, incidentally, is 14-136ins. in diameter) is conveyed through differential gearing of orthodox and robust design by two short shafts flanged at the outer ends. To these flanges are coupled directly two constant-velocity universal joints, which form the inner units of the final drive to the front road wheels. The outer constant-velocity universal joints which work through a considerably larger angle than the inner ones are mounted in line with the pivot pins of the front wheels. Each outer universal joint is connected to the inner driving member of a front-wheel hub. Suspension of the . eiagine-gearboxworm unit is arranged at three points, two of which are located on a largediameter cross-tube, which forms one of the main structural members of the front end of the vehicle, whilst the rear point of support, at the rear of the engine, is braced back to the main bulkhead so as to resist torque.

The entire vehicle is mounted upon independently sprung wheels. In the case of the front wheels Gruss air springs of a large size take the entire load. The driving and braking stresses and braking torque are taken care of by vertical guide bars, thereby relieving the air springs of all loading other than the vertical. These guide bars are attached to the non-pivoting portion of the front-wheel hub housing on each side of the vehicle, and slide through bushes contained in the outer casing of thG Gruss air spring. The rear-wheel suspension is effected in a similar manner, but with a slightly different construction.

The body shell forms the main structure of the chassis to which the units are attached, the usual chassis-frame members being completely dispensed with. The wheel-arches provide a bridge-like construction, to which the independently sprung wheels are attached. These wheel-arches are built into the main body structure, the front pair being braced together by the tubular member which carries the front support of the power-and-drive unit, whilst the rear two wheel-arches are directly connected by deep-section channel members, to which are rigidly fixed two longitudinal channels extending rearward to support the overhang. As to the main framework formation the front and rear wheel-arches are connected by a sturdy form of metal construction, which lends itself to economic production and replacement of parts. The side panelling below the waist is of sufficient thickness to make it one of the main factors of strength of the whole framework. The structural members are of rolled-steel box section, com binEng strength with lightness. The outstanding advantage derived from this construction is the extremely low floor level, which is 13-1 ins, laden, whilst the clearances called for under the Ministry of Transport Regulations are claimed to be fully complied with. The low height of the flooring enables a double-saloon vehicle to be built within an overall height of 12 ft. 11 ins., although having perfectly flat floors on both lower and upper decks.

The weight 'distribution is practically equal between the front and rear wheels when the vehicle is fully laden, thereby ensuring, under all conditions, an efficient road grip for the driving wheels. This permits the use of single rear tyres and full advantage of the fact is taken by fitting large low-pressure tyres, the size being 11.25 ins. by 20 ins. The wheels are all detachable and interchangeable.

The steering gear is of the well-known Marks cam-and-roller type, and the steering of the vehicle is said to have wove d exceptionally easy under test anditions. As regards braking the service brake operates on all four wheels through the Lockheed hydraulic system, which gives balanced application between the wheels, and power assistance is obtained by Dewandre vacuuffr cylinder, the pneumatic and hydraulic components forming a unit. The hydraulic shoe-applying cylinders are mounted externally and operate on the orthodox cam levers. As is the usual practice on Gifford vehicles the brake camshafts are mounted on roller bearings. The brake drums are ribbed for strength and cooling. The hand brake operates on the rear wheels only. Equipment includes a complete bus lighting and starting outfit, with the usual accessories.