MORE FOR LESS

Page 62

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

Every tipperman knows exactly what he wants from his vehicles: TipCon offers manufacturers the chance to show how close they can come to meeting these impossible demands.

• If a tipper operator were asked to write his own vehicle specification, the resulting truck would weigh next to nothing. It would run on air, need no servicing and last for ever. Sorry, none of the exhibits at next week's RHA TipCon exhibition will meet that ideal, but there are a number which go some way towards improving overall productivity and reducing running costs.

One of the lightest three-axle rigids around is ERF's ES8 6x4 tipper, launched at the end of 1989. Based on the E8 chassis, its powertrain consists of a Cummins 6CTAA (air-to-air) chargecooled engine rated at 183kW (245hp) installed; an Eaton 6109 nine-speed synchromesh gearbox and Rockwell S160 double-drive bogie. The composite-cabbed E8 weighs in at 6.74 tonnes but the ES8, with a slightly longer 4.3m wheelbase and equipped with the small steel Steyr cab, is around 200kg lighter. ERF has priced it at slightly below its stablemate, but with a bigger payload potential it is a rare example of getting more for less.

Even the ES8 can't match the low chassis weight of Seddon Atkinson's latest six-wheeler. It uses the same engine and gearbox but, specified with Norde rubber suspension and its own RA-472 axles on a 4.3m wheelbase 3-11 chassis-cab has an unladen weight of 6,370kg.

This represents a gain of 300kg compared with the equivalent Cummins L10-250 powered 3-11.

As exclusively reported in Commercial Motor, Seddon Atkinson plans to phase

out the RA-475 axles in favour of the Rockwell SRHD bogie which incorporates both inter-axle and cross-axle difflocks as standard. Seddon Atkinson does not plan to replace the MP cab on this lightweight chassis with day or sleeper versions of the Strato cab as will be done with other 3-11 rigids.

Down a class in weight, and from down the road at Sandbach, Foden's new 17tonner offers an extemely competitive body payload allowance of 12.3 tonnes. It also conforms to the Cummins/Eaton/ Rockwell driveline but uses the B Series engine, which offers an output of 134kW (180hp), and a six-speed 4106 gearbox. Again it is the cab that makes the difference. Like the ERF E8 and E8 17tonners, the 2000 Series employs a composite cab. Front and rear loading compatability should be satisfied by its 7.1-tonne front-axle rating, allowing a tolerance of 600kg.

With a full tank of fuel, MercedesBenz's 1733S 4x2 day cab tractive unit weighs in at just over six tonnes. No other unit with a power-to-weight ratio as high as 6.53kW/tonne (8.9hp/ton) offers such payload potential. Its compact 11litre vee-six air-to-air charge-cooled engine, developing 249kW (338hp) at 2,100rpm and 1,365Nm (1,00Mb/ft) of torque from 1,000 to 1,600rpm, is matched to Mercedes-Benz's own 16speed, range-change/splitter, synchromesh gearbox incorporating EPS (electronic power shift).

It is equipped with automatic lubrication and service intervals have been set at 45,000km (28,0000 miles) for long haul, and at 30,000km (19,000 miles) for multidrop operations. Manual greasing is eliminated except for the prop-shaft bearings, which have been designed to accept the longer service intervals.

Coupling to one of Don-Bur's new allaluminium tipping trailers would seem a sure way to maximise payload capacity. The company's Paylowda design is available with capacities of up to 43m3 (56yd3). Both body and chassis are

manufactured from high-strength N8 alloy. Its aluminium taper frame saves over 400kg compared to an equivalent steel chassis, and even when fitted with air suspension it offers a whopping potential 26.5 tonnes of payload.

Tipping stability is always a problem so any improvement in semi-trailer design that can improve matters must be welcome. York's new 2000 Series tipping trailers are said to provide a much higher standard of basic equipment at no extra cost. The specification includes Tecair suspension, antilock braking, premium tyres, premium front-end hoist and spring park brakes. But the principal benefit comes from increasing the frame centres to l,4(X)mm and indirectly widening the spring base. Combined with a stiff chassis construction this is said to improve its resistance to roll by almost 40%.

POPULAR

Twin and triple-ram underfloor tipping gear from Harsh has grown in popularity over recent years. The company claims a 52% sales increase over last year, even though the multi-axle rigid vehicle market is running at 30% below 1989 levels. Market acceptance is credited to the stability of the Harsh scissor lifting mechanism. Unlike front-end hoists, where a single ram has to provide both lift and lateral stability: the Harsh system uses the rams in a purely lifting capacity, leaving the main frame assembly to prevent any sideways movement.

Wilcox Seadyke's Ejectaload system, the latest addition to the company's range of aluminium alloy, bodies, provides a safe alternative to the discharge of low-density waste. The 70M example on show at Harrogate offers up to a tonne more payload than an equivalent steel-bodied semi-trailer. The ejection head is powered by an Edbro hard-chromed ram, for smooth and durable operation.

Durability and access are two features built into the first alloy body to be

marketed by Crane Fruehauf for rigid tipping chassis. Originating from sister company Benalu in France, the 19.8m3 (26y13) body is representative of the product range available through Crane Fruehauf's Continental operation. The show model has an internal length of 6.6m, is 2.3m wide and 1.3m deep, constructed with an 8mm-thick floor and 6mm sides. The rear 2.2m of the floor section is fitted with a replaceable 4mm overlay.

Unplanned servicing due to premature brake wear can be reduced significantly by auxiliary braking. The Telma electromagnetic retarder's new rotor design gives an improved weight-toperformance ratio. Installed in the drive line of a tractive unit or multi-axle rigid it can provide up to 80% of braking requirements, ensuring that the foundation brakes remain cool. Less brake wear reduces overall maintenance costs and Lime off the road: the pay-back time is claimed to be as little as 12 months.

An alternative solution is offered by IMS with the SAF-Vorth hydrodynamic retarder for semi-trailers. The braking action causes no wear to its components and generated heat is dissipated through an integral cooling system. The main disadvantage of either system is that they add to the vehicle's unladen weight.

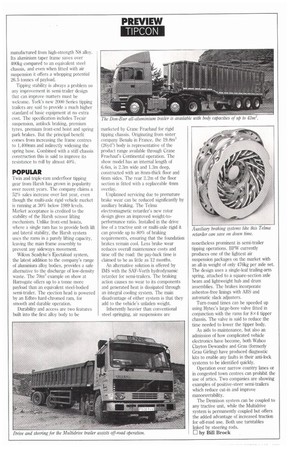

Inherently heavier than conventional steel springing, air suspensions are nonetheless prominent in semi-trailer tipping operations. BPW currently produces one of the lightest air suspension packages on the market with an all-in weight of only 476kg per axle set The design uses a single-leaf trailing-arm spring, attached to a square-section axle beam and lightweight hub and drum assemblies. The brakes incorporate asbestos-free linings with ABS and automatic slack adjusters.

Turn-round times can be speeded up using Hytec's large-bore valve fitted in conjunction with the rams for 8x 4 tipper chassis. The valve is said to reduce the time needed to lower the tipper body.

As aids to maintenance, but also an admission of how complicated vehicle electronics have become, both Wabco Clayton Dewandre and Grau (formerly Grau Girling) have produced diagnostic kits to enable any faults in their anti-lock systems to be identified quickly.

Operation over narrow country lanes or in congested town centres can prohibit the use of artics. Two companies are showing examples of positive-steer semi-trailers which reduce cut-in and improve manoeuvrability.

The Dennison system can be coupled to any tractive unit, while the Multidrive system is permanently coupled but offers the added advantage of increased traction for off-road use. Both use turntables linked by steering rods.

by Bill Brock