Sidewinder's rapid ratchet

Page 154

Page 155

If you've noticed an error in this article please click here to report it so we can fix it.

Air tools are convenient but not always available. We look at an alternative.

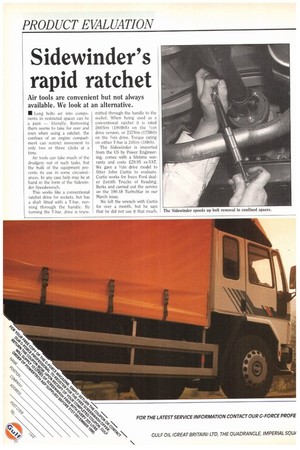

• Long bolts set into components in restricted spaces can he a pain — literally. Removing them seems to take for ever and even when using a ratchet, the confines of an engine compartment can restrict movement to only two or three clicks at a time.

Air tools can take much of the drudgery out of such tasks, but the bulk of the equipment prevents its use in some circumstances. In any case help may he at hand in the form of the Sidewinder Speedwrench.

This works like a conventional ratchet drive for sockets, but has a shaft fitted with a 1-bar, running through the handle. By turning the 1-bar, drive is trans

mitted through the handle to the socket. When being used as a conventional ratchet it is rated 260Nm (1901bft) on the 1/2in drive version, or 237Nm 1175111ft) on the 'Vain drive. Torque rating on either 1-bar is 24Nm (18Ibft).

The Sidewinder is imported from the US by Power Engineering, comes with a lifetime warranty and costs £29.95 ex-VAT. We gave a 1/2in drive model to fitter John Curtis to evaluate. Curtis works for lveco Ford dealer Zenith Trucks of Reading. Berks and carried out the service on the 190.48 TurboStar in our March issue.

We left the wrench with Curtis for over a month, but he says that he did not use it that much. The problem is that when using it as a conventional ratchet, the 1-bar keeps turning and catches your wrist," he explains. If the 1-bar could be disengaged or was replaced with a knurled nut, he says the problem would be cured.

With a torque rating of just 24Nm on the 1-bar it is clear that it is not meant for undoing tight bolts, so maybe his suggestion is not without merit.

One aspect of the wrench he does like is that the ratchet direction switch is set on the underside of the head. So if you undo a bolt and find that it has not cleared the hole before the back of the wrench hits an obstruction, you can switch the ratchet direction and wind the bolt back in again. Obviously with the switch set on the back of the ratchet this becomes extremely difficult — a fault Curtis finds on some air tool designs.

Starter motor

Curtis will not be buying a-Sidewinder himself, but feels that those who are repeatedly handling jobs where access is restricted or where airlines are not available would find the tool very useful. One such job that he did come across was the top bolt securing the starter motor on a Ford vee-six engine. Having loosened the bolt using the Sidewinder in its conventional ratchet mode he was able to "spin the bolt out using the 1-bar.

Even where room allows, air tools are undesirable for some jobs, such as fitting or removing a spark plug. With the Sidewinder, says Curtis, you keep the "feel" of the job and should detect cross-threading or other problems before too much damage is done.

There is also the need to exhaust air from pneumaticallydriven tools. lithe truck is very dusty (say a tipper working on site during a dry spell) the exhaust may blow the dust all over the unfortunate fitter and some asbestos friction linings are still in use.

Curtis feels that there is a place for the Sidewinder, but mainly for those who do not have the facilities available at Zenith or those who repeatedly need to remove and retighten bolts in areas too restricted for air tools.