Carrimore's Latest Products,

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

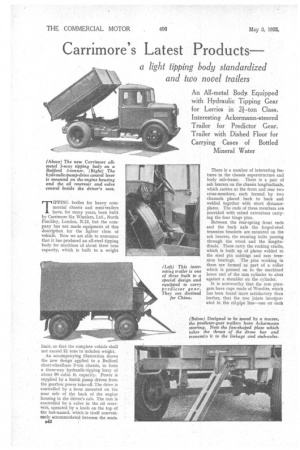

TIPPING bodies for heavy commercial chassis and semi-trailers have, for many years, been built by Carrimore Six Wheelers, Ltd., North Finchley, London, N.12, but the company has not made equipment of this description for the lighter class of vehicle. Now we are able to announce that it has produced an all-steel tipping body for machines of about three tons capacity, which is built to a weight limit, so that the complete vehicle shall not exceed 21 tons in unladen weight.

An accompanying illustration shows the new design applied to a Bedford short-wheelbase 3-ton chassis, to form a three-way hydraulic-tipping lorry of about 90 cubic ft. capacity. Power is supplied by a Smith pump driven from the gearbox power take-off. The drive is controlled by a lever mounted on the near side of the back of the engine housing in the driver's cab. The ram is controlled by a valve in the oil reservoir, operated by a knob on the top of the last-named, which,is itself conveniently accommodated between the seats.

1142

There is a number of interesting features in the chassis superstructure and body sub-frame. There is a pair of ash bearers on the chassis longitudinals, which carries at the front and rear two cross-members, each formed by two channels placed back to back and welded together with short distanceplates. The ends of these members are provided with raised extensions carrying the four hinge pins.

Between the rear-spring front ends and the back axle the forged-steel trunnion brackets are mounted on the ash bearers, the securing bolts passing through the wood and the longitudinals. These carry the rocking cradle, which is built up of plates welded to the steel pin castings and ram trunnion bearings. The pins working in these are formed as part of a collar which is pressed on to the machined lower end of the ram cylinder to abut against a shoulder on the cylinder.

It is noteworthy that the ram plungers have cups made of Woodite, which has been found more satisfactory than leather, that the two joints incorporated in the oil-pipe line—one on each trunnion axis—are Flextile joints, products of W. H. Dorman and Co., Ltd., Stafford, and that all connections in the line are made with Simple-fix unions. All trunnions are provided with greasers.

Two light " fish-bellied " pressings, of box-section for the greater part af their length but channel at their tapered ends, form the longitudivals of the body sub-frame. Attached to these are two short cross-channels to which the upper end of the ram plunger is universally jointed, and two pairs of channels forming body cross-members and having the tipping-hinges at their ends. These hinges are hollow steel castings, and rest upon the hinge pins, referred to earlier, each having a detachable securing pin.

The body is of standard Carrimore construction, electrically welded throughout and provided with dropsides aria a tailboard hinged at both top and bottom. The dimensions are approximately 8 ft. long, 6 ft. 6 ins. wide and 1 ft. 9 ins. high. The weight with tipping gear, etc., as illustrated, is less than 17 cwt.

We inspected this machine a few days ago, and were also shown in the Carrirnore works two interesting trailers, photographs of which are reproduced. The first is one of three built to the order of a well-known armament engineer, and is, we understand, to be exported to China, for carrying predictor gear, which includes a small petrol-engined electric generating plant, large coils of cable and various field apparatus.

Perhaps its most interesting feature is the use of Ackermann steering. This is simply arranged in the following manner. The forked end of the hinged I-section drawbar embraces a large vertical fan-shaped extension on a swivelling lug. To this quadrant-plate the turning moment (about a vertical axis) is imparted by the drawbar. Thence it is transmitted to the stub-axles by a steering arm, ball-jointed link and track rod an the usual manner. The front axle bed is square and of 55-ton high-tensile steel, with the high-tensile forged jaw-ends pressed and welded on.

Designed to carry loads up to 4 tons, the trailer is equipped with a sturdy Oak tilt body, fitted with cupboards, benches, and mountings for the special appliances, etc. The box seat at the front gives it R rather odd appearance, and its object is not obvious in view of the fact that the machine is, we are informed, to be towed exclusively by a tractor.

Details worthy of mention are the employment of sheet-metal roof corners, joining the appropriate wood-filleted channel-steel longitudinals, carried by the angle-iron roof sticks, the extension of the floor beyond the sides of the body to form external recesses for the accommodation of certain items of the predictor equipment, and the neat rear step which folds, when out of use, into a hole in the tailboard.

The other interesting Carrirnore trailer is a 2-3-tonner, of the platform type, built for the Direct Supply Aerated Water Co., Ltd., for carrying boxes of bottled mineral water. Its outstanding feature is the dished floor, the object, of course, being to provide that the boxes placed near the sides lean inwards against those along the centre of the platform.

This vehicle has a fixed rear board, it being normally loaded from the sides, and unloaded from the sides and front. Mechanical points of interest arc the unusually wide track and the Carrimore pinless turntable.