An Electrically Controlled Gearbox

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

L'OR some time past an interesting type of epicyclic gear.I.box has been available in France and has been tested by many makers of commercial vehicles and private cars. A policy of steady development has been pursued by those responsible, and this mechanism, which is known as the Cotal transmission, has reached a highly practical stage in design and construction.

Quite recently. the Cotal Chaclburn Co., Ltd., 9, Cloak Lane, Cannon Street., London, E.C.4, was formed to develop the Cotal transmission in England, this concern having the power to grant licences to manufacturers of vehicles. Additionally, Bean Industries, Ltd., a concern which is a subsidiary of Hadfields, Ltd., is manufacturing the Cotal gearbox for those wishing to test it or to buy it in quantities as a component.

The outstanding feature of the mechanism is the use of electro-magnets, in place of brakes operated by springs or hydraulic pressure, for the control of the various elements in the epicyclic mechanism. Consequently, the gear lever is merely used to operate a simple switch, whereby current li diverted to the electro-magnets required.

The gear lever, which can be arranged in any one of many ways, provides a neutral position and four gear posi tions. Additionally, there is another lever which gives direct control of the coupling mechanism employed for ferward and reverse. Normally, this auxiliary lever is left in the forward-speed position, the vehicle -being driven by means of the electric-switch lever and an ordinary clutch and clutch pedal.

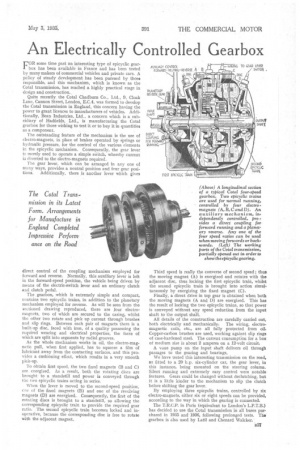

The gearbox, which is extremely simple and compact, contains two epicyclic trains, in additionto the planetary mechanism employed for reverse. As will be seen from the sectioned drawing reproduced, there are lour electromagnets, two of which are secured to the casing, whilst the other two rotate and pick up current through brushes and slip rings. Between each pair of magnets there is a built-up disc, faced with iron, of a quality possessing the required wearing and electrical properties, the faces of which are split into segments by radial grooves.

As the whole mechanism works in oil, the electro-magnetic pull, when first applied, has to squeeze a film of lubricant away from the contacting surfaces, and this provides a cushioning effect, which results in a very smooth pick-up.

To obtain first speed, the two fixed magnets (B and C) are energized. As a result, both the rotating discs are brought to a standstill and power is conveyed through the two epicyclic trains acting in series.

When the lever is moved to the second-speed position, one of the fixed magnets (B) and one of the revolving magnets (D) are energized. Consequently, the first of the rotating discs is brought to a standstill, so allowing the corresponding epicyclic train to provide the required gear ratio. The second epicyclic train becomes locked and inoperative, because the corresponding disc is free to rotate with the adjacent magnet.

Third speed is really the converse of second speed ; thus the moving magnet (A) is energized and rotates with the adjacent disc, thus locking the first epicyclic train, whilst the second epicyclic train is brought into action simultaneously by energizing the fixed magnet (C).

Finally, a direct drive in top gear is obtained when both the moving magnets (A and D) are energized. This has the result of locking the two epicyclic trains, so that power is conveyed without any speed reduction from the input shaft to the output shaft.

All details of the construction are carefully carried out, both electrically and mechanically. The wiring, electromagnetic coils, etc., are all fully protected from oil. Copper-carbon brushes are used, working against slip rings of case-hardened steel. The current consumption for a box of medium size is about 2 amperes on a 12-volt circuit.

A vane pump on the input shaft delivers oil through passages to the gearing and bearings.

We have tested this interesting transmission on the road, as fitted to a 20 h.p. six-cylinder car, the gear lever, in this instance, being mounted on the steering column. Silent running and extremely easy control were notable features. Gears could be changed without declutching, but it is a little kinder to the mechanism to slip the clutch before shifting the gear lever.

By employing three epicyclic trains, controlled by six electro-magnets, either six or eight speeds can be provided, according to the way in which the gearing is connected.

The T.R.C.P. in Paris (equivalent to London's L.P.T.B.) has decided to use the Cotal transmission in all buses purchased in 1985 and 1936, following prolonged tests. The gearbox is also used by Latil and Chenard Walcker.