CHASSIS FEATURES

Page 88

Page 89

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

that make for

ECONOMIES

IF a consensus of opinion On road transport were taken from all operators in the world—both large and small—they would as one voice express a desire for low-priced vehicles which are economical to TIM and to maintain. Chassis manufacturers, of course, virtually say in reply that the vehicles produced now are priced as low as possible, and they represent the highest efficiency that existing knowledge -will allow them to produce ; it must be admitted that, in the great majority of cases, they are right.

Until a further stage in development occurs, then, one might be tempted to argue that everything is as good as it can be, and, therefore, why worry about it? This, however, is not by any means the whole story, and it will be our object in this article to show how a wise choice of vehicles can make all the difference between a good balance-sheet and a bad one at the end of the financial year.

What is Economy ?

It Would seem to be desirable first of all to examine the exact meaning of economy, as applied to road vehicles. In a few words this may be taken as identifying low cost per load-mile or ton-mile, and so every phase of the transport industry is taken into account, purchase price, running cost, frequency of and expensiveness of overhauls, and the life of the vehicle all being intimately connected.

One can, for example, easily make a misguided purchase of a low-priced vehicle only to find that it is not ideally suited to the requirements which an operator has in view. We are not now referring to the size of a platform for certain loads—that is obvious—but to the more subtle dissemination of performance facts and figures which, during the life of a vehicle, have such a large bearing on the total cost of operation.

In the academic sense the size, the strength and wearing qualities of a chassis should be so balanced that everything falls at one time, i.e., the engine cylinders should be so worn that regrinding and fitting new pistons is impossible, the crankshaft journals should be irreparably worn, all the gearbox components, pinions, shafts, bearings, etc., together with propeller shaft and rear-axle components, brakes, etc., should, at the same time, become worn beyond the possibility of replacing the parts. Then the life of every component would be of exactly the same duration.

This is, of course, utterly impossible of attainment, but one has to recognize that chassis will not last for ever, so that an economic limit, which involves the factors of " cost" and "life," has to be determined.

Points to Consider.

It can here be said that, in general, most discriminating operators can pick out chassis suitable for their requirements merely by making a detailed examination of the sizes and the disposition of the components used for the working parts, but it is doubtful whether many prospective purchasers examine the power and fuel-consumption curves of an engine and by correlating these characteristics to the required road performance arrive at the best selection.

Take a hypothetical case depicted in the lower left-hand graph. The performance curves shown are fairly representative of a large six-cyliudered engine, and the r.p.m. and m.p.h. figures have been correlated in a simple manner so that comparison is easy. The lower curve shows the fuel consumption taken over the whole range of speed ; admittedly this is for the full-throttle position, but it bears some relation to the consumption when the throttle is eased to a small extent.

Now, suppose that an operator requires a vehicle to run at 20 m.p.h. to 25 m.p.h. for the major portion of its life and will require about 40 b.h.p. to maintain such a speed. It might, at first sight, appear that an engine with characteristics such as those shown in graph 2 is too large and that a unit which develops 60 b.h.p. at, say 2,500 tr.p.m. could, when suitably geared, be employed. These characteristics are seen in the upper graph on the preceding page.

The fuel-consumption curve should again be noted, for assuming that from 40 b.h.p. to 60 b.h.p. would be required such a power unit would be operating at about its maximum output and revolution speed all the time the vehicle is running, and the fuel consumption would be at the rate of 0.8 pint per b.h.p.-hour instead of, say, 0.6 pint per b.h.p.-hour as in the former engine. Now, taking an average speed of 20 m.p.h. and an average power of 40 b.h.p., this difference represents 2,500 gallons of fuel over a mileage of 50,000—or £125 taking fuel at 1s. per gallon. This figure may be slightly high, but it should represent at least f100. It would, therefore, pay well to incorporate the larger engine, although an extra charge of, say, £50 has to be allowed for.

Suitability of Engine.

Again, one should weigh up the suitability of a power unit for the particular work to which it will be put. Suppose, for example, it is desired to run a fleet of vehicles in which relatively high speed and good acceleration are of paramount importance. It would be futile to purchase a low powered machine where the engine will be " worked to death" by being run for relatively long periods all out " on the indirect gears—a practice which not only is wasteful of power, but is calculated to give a high fuel consumption as well as heavy stressing of the working compon ents. This is another case where a larger engine working well within its capacity would be an advantage.

On the other hand, there are many uses for which a small-powered vehicle is ideally suited. Delivery work in fiat districts (such as the Fenlands where stopping places are a relatively long distance apart) is a case in point ; the speed of delivery would not be greatly affected and the cost of operation would, of course, be much lower than by employing a high-powered machine with consequent heavy stresses which require additional strength and weight in both chassis and bodywork.

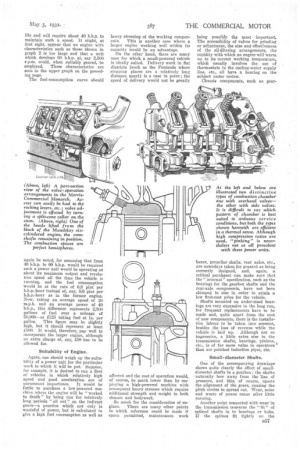

So much for the consideration of engines. There are many other points to which reference could be made if space permitted, maintenance work being possibly the most important. The accessibility of valves for grinding or adjustment, the size and effectiveness of the oil-filtering arrangements, the rapidity with which an engine will warm up to its correct working temperature, which usually involves the use of thermostats in the cooling-water supply line, etc., all have a bearing on the subject under review.

Chassis components, such as gear boxes, propeller shafts, rear axles, etc., are nowadays taken for granted as being correctly designed, and, again, a critical purchaser can make sure that the" internal" specification, such as the bearings for the gearbox shafts and the rear-axle components, have not been skimped in size in order to attain a low first-cost price for the vehicle.

Shafts mounted on under-sized bearings are very expensive in the long run, for frequent replacements have to be made and, quite apart from the cost of new components, there is the installation labour to be taken into account, besides the loss of revenue while the vehicle is laid up. Although not so impressive, a little extra size in the transmission shafts, bearings, pinions, etc., is of far more value to operators s than are polished induction pipes, etc.

Small-diameter Shafts.

One of the accompanying drawings shows quite clearly the effect of smalldiameter shafts in a gearbox ; the shafts -naturally bow away from the line of pressure, and this, of course, upsets the alignment of the gears, causing the pitch circles to spread out. Wear, noise and waste of power ensue after little running.

Another point connected with wear in the transmission concerns the " fit " of splined shafts in to bearings or hubs. If the splines fit tightly on the diameters, with slight clearances between the driving faces, wear will take place rapidly. As everyone knows, this is a malady which develops rapidly, soon calling for replacement of parts. It is obvious, therefore, that (expressed in, engineering parlance) the diameters should be clear and the driving faces given a tight rotational fit so as to obtain long life and freedom from trouble.

It is known that to overload bearings to such an extent that the oil film be destroyed is literally asking for trouble, yet, in many cases, although the road-spring shackle pins are known to be of rather meagre dimensions, even knowledgeable operators fail to attend regularly to lubrication. This is often due to the grease nipples being rather

difficult to get at. It is desirable, however, that shackle pins and bushes with large surfaces should be employed and their lubrication attended to regularly. One of the accompanying drawings shows how the loading per square inch very rapidly decreases by reason of a slight increase in diameter for the pins.

Braking Effort.

Finally, a word concerning brakes may not be out of place. Nowadays, the retarding mechanism of most vehicles is extremely efficient, and, with the help of servo motors, the effort required to be exerted by the driver to effect an emergency stop of even a heavily laden vehicle is quite moderate. Consequently, one is apt to forget the enormous amount of mechanical effort which is exerted when the brake pedal is fully depressed.

The importance of diameter of the drums and shoes is most marked. Broadly speaking, the contacting pressure between the drums and the shoes varies inversely as the diameter, which means to say that all the components in a brake linkage in which largediameter drums are employed are lightly loaded, whilst with small-diameter drums they are proportionately more heavily stressed.

From the foregoing brief analysis it will be seen that economic operation is "built into a vehicle," and operators should, when considering the purchase of chassis, go carefully into the specification of all components.