Advanced Methods in Cesspool Emptying

Page 132

Page 133

If you've noticed an error in this article please click here to report it so we can fix it.

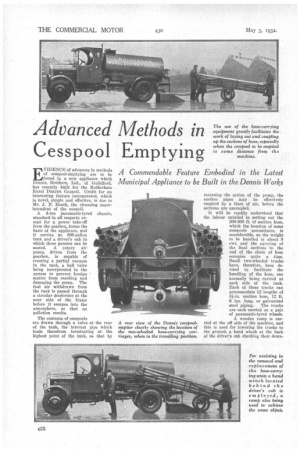

EVIDENCE of advances in methods of cesspool-emptying are to be found in a new appliance which Dennis Brothers, Ltd., of Guildford, has recently built for the Rotherham Rural District Council. Credit for an interesting feature incorporated, which is novel, simple and effective, is due to Mr. J. F. Heath, the cleansing superintendent of the council.

A 4-ton pueumatic-tyred chassis, standard in all respects except for a power take-off from the gearbox, forms the basis of the appliance, and it carries an 800-gallon tank and a driver's cab in which three persons can be seated. A rotary air pump, driven from the gearbox, is capable of creating a partial vacuum in the tank, a ball valve being incorporated in the system to prevent foreign matter from reaching and damaging the pump. The foul air withdrawn from the tank is passed through a circular deodorizer at the near side of the frame before it escapes into the atmosphere, so that no pollution results.

The contents of cesspools are drawn through a valve at the rear of the tank, the internal pipe which leads therefrom terminating at the highest point of the tank, so that by reversing the action of the pump, the suction pipes may be effectively emptied by a blast of air, before the sections aro uncoupled.

It will be readily understood that the labour entailed in setting out the 200-300 ft. of suction hose, which the location of some cesspools necessitates, is considerable, as the weight to be handled is about 8 cwt. and the carrying of the final sections to the end of the chain of hose occupies quite a time. Small two-wheeled trucks have, therefore, been devised to facilitate the handling of the hose, one normally being carried at each side of the tank. Each of these trucks can accommodate 12 lengths of 3i-in. suction hose, 12 ft. 6 ins, long, or galvanized

steel piping. The trucks are each carried on a pair of pneumatic-tyred wheels.

A wooden ramp is carried at the off side of the machine, and this is used for lowering the trucks to the ground, a hand winch at the back of the driver's cab checking their down

ward travel and assisting-in-their replacement. The undercarriage of each truck is attached to its superstructure in such a way that it is free to slide, and the rearward position of the wheels during transportation on the vehicle enables the equipment to be compactly disposed.

At Rotherham, a routine ensures periodical attention to every cesspool in

rotation and, consequently, it frequently happens that two or more adjoining properties have to be visited in succession. The capacities of cesspools vary considerably, but on an average they approximate 750 gallons apiece ; that is to say, the contents of each will provide nearly a full load for the Dennis machine, and this must be discharged before the next cesspool can be dealt with. With the assistance of the suction carriages it is an easy matter for two men to pack up the hose on one property and to deposit it at the site next to be visited while the appliance proceeds to the tip to evacuate the contents of the tank. Upon its return to the scene of operations, the vehicle can once again resume its emptying duties with a minimum loss of time.