A New Suction-type Tipping Gear

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

The Clayton-Gauthier Poweroperated Mechanism Dispenses with All Mechanical Connection from the Engine

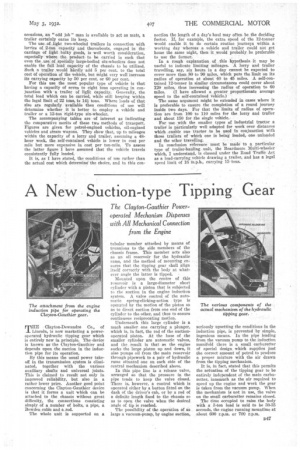

THEClayton-Dewandm Co., of ;Lincoln is now marketing a poweroperated hydraulic tipping gear which is entirely new in principle. The•device is known asthe Clayton-Gauthier and depends upon the suction in the induction pipe for its operation.

By this means the usual power takeoff in the transmission system is eliminated, together with the various auxiliary shafts and universal joints. This is claimed to result not only in improved reliability, but also in a rather lower price. Another good point concerning the Clayton-Gauthier device is that it forms a unit which can be attached to the chassis without great difficulty, the connections consisting simply of a number of bolts, •a pipe, a Bowden cable and a-rod.

The whole unit is supported on a

tubular member attached by means of trunnions to the side members of the chassis frame. This member acts also as an oil reservoir for the hydraulic

rams, and the method of mounting-ensures that the tipping gear shall align

itself correctly with the body at whatever angle the latter is tipped.

Mounted upon the centre of this reservoir is a large-diameter short cylinder with a piston that is subjected to the suction in the engine induction system. A valve control of the automatic spring-clicking-action type is operated by the motion of the piston so as to divert suction from one end of the cylinder to the other, and thus to ensure continuous reciprocating motion.

"Underneath this large cylinder is a much smaller one carrying a plunger, which is, in fact, the rod of the suction' operated piston. At the base of the smaller cylinder are automatic valves, and the result is that as the engine sucks the large piston up and down, it also pumps oil from the main reservoir through pipework to a pair of hydraulic rams situated one on each side of the central mechanism described above.

In this pipe line is a release valve, arranged so that the pressure in the pipe tends to keep the valve closed. There is, however, a control which is operated either by a button fitted on the dash of the driver's cab, or by a rod of a definite length fixed to the chassis so as to open the valve when the desired angle of tip is reachod.

The possibility of the operation of so large a vacuum-pump, by engine suction, seriously upsetting the conditions in the induction pipe, is prevented by simple, ingenious means. In the pipe leading from the vacuum pump to the induction manifold there is a small carburetter of special design which supplies just the correct amount of petrol to produce a proper mixture with the air drawn from the tipping mechanism.

It is, in fact, stated that this permits the actuation of the tipping gear to be entirely independent of the main carburetter, inasmuch as the air required to speed up the engine and work the gear is taken from the vacuum pump. When the mechanism is not in use, the valve on the small carburetter remains closed.

The time occupied to raise the body with a 3-ton load is said to be 20-35 seconds, the engine running meantime at about 600 r.p.m. or 700 r.p.m.