TRIAL

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

and ERROR

IHAVE recently dealt with an interesting problem on behalf of a C-licensee concerning how the haulage of 100 tons of cereals from the docks each day to a mill over a distance of 30 miles could best be done. The route was fairly easy; 25 miles of the 30 were on a good open highway, the remaining five miles through congested streets of a city and possibly the difficult ways to the docks.

I was told that, under present conditions, six men could transfer the 100 tons per day from the dock warehouses to the lorries and I assumed that the same number was required to unload vehicles at the mill. It seemed likely that mechanical means for handling were available in order to enable these men to do that work in the time.

At the unloading end, there appeared to be no limit as to the hours during which the work of unloading could proceed: I was told that the men there worked in shifts from 6 a.m. to 2 p.m., from 2 p.m. to 10 p.m., and if necessary, from 10 p.m. to 6 a.m., which relieved me of any anxiety as to the times at which vehicles should arrive with their loads at that end of the journey.

At the dockside, matters were not so convenient. Loading could take place only between the hours of 8 a.m, and noon, and 1 p.m. and 5 p.m. On Saturdays. loading took place from 8 a.m. until noon.

I was given free choic. as to the type and capacity of vehicle to be employed. The inquirer mentioned trailers in his letter, but if he thought of trailers used in conjunction with ordinary loaded lorries I do not see any point in employing them. I was requested to make provision in my estimate for the cost of a spare vehicle, as it was thought that continuity of traffic was so important as to make that essential. I was further told that the wages of the loading and unloading crew were £4 10s. per week per man.

When i first read the letter containing this data, the problem seemed to be

simple. I jumped to the conclusion that four maximum-load six-wheelers, each carrying a 121-ton load, would suffice, and assuming that they could do two journeys per day, they would carry 100 tons exactly, and I went into the proposition on that basis. In doing so, however, I was wrong.

Each vehicle would, I reckoned, running two journeys per day, cover 120 miles daily from Monday to Friday and. allowing for a further 60 on Saturday, that would give a total of 660 miles per week per vehicle.

1 worked out the cost on the basis of one vehicle only. The cost per mile of t-22 an oil-engincd vehicle, according tc present-day figures, is is. 24d. I assumed that a mate would be carried, and allowing an approximate figure of £5 per week on his account, that is equivalent to another lid, per mile. I reckoned on overheads, a further E5 per week, which gives me another 14d. per mile.

As regards loading and unloading, I made the dssumption that the driver and mate would help in this work at each end of the journey. If that be the case, then I need make allowance for only four labourers at the mill and four at the docks. Allowing E5 per week each for them (allowance being made for general insurance and holiday pay in addition to the £4 10s. already mentioned) there is in that a total of £40 per week, which is equivalent to another Is. 2.1d. per mile.

Finally, I had to make allowance for the cost of keeping a spare vehicle, and I took that also to be £5 per week. which is a further lid, per mile.

The total of the above items is 2s. 10d. per mile, so that the cost of one journey of 60 miles is £8 10s., approximately 13s. 6d. per ton. That, according to the inferences I have drawn from the letter, is a little more than the cost was expected to be.

I then checked the possibility of making two trips a day. For a 30-mile journey under the conditions named, from 11 to 2 hrs. would be. necessary. Taking the round figure of 2.hrs., I have then a total of 4 hrs. for travelling, 2 hrs, for loading and 1 hr. for unloading. Obviously, therefore, two journeys per day are impracticable.

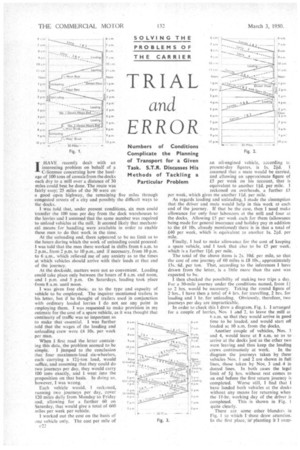

In order to check this I drew a diagram. Fig. 1. 1 arranged for a couple of lorries, Nos 1 and 2, to leave the mill at 6 a.m, so that they would arrive in good time to be loaded, and would start off a.:n loaded at 10 a.m, from the docks.

Another couple of vehicles, Nos. 3 and 4, would leave at 8 a.m. so as to arrive at the docks just' as the other two were leaving and thus keep the loading crews continuously at work. In the diagram the journeys taken by these vehicles Nos. 1 and 2 are shown in full lines, those taken by Nos, 3 and 4 in dotted lines. In both cases the legal limit of 51 hrs. without rest comes to an end before the first return journey is completed. Worse still, I find that I have landed both vehicles at the docks without any means for returning when the II-hr. working day of the driver is completed. This • is Shownin Fig. 1 quite clearly.

There are some other, blunders in Fig. 1 to which I Must draw attention. In the first place, in' planning it'I'Over

looked the fact that the docks dose at 5 pin. Secondly, I left a big gap between the dose of the dinner hour at the docks at 1 p.m. and the arrival of the next vehicle for unloading at 3.30 p.m. I realized, too, on scrutinizing this diagram, that I had wasted half an hour of each vehicle's time by providing for the drivei to take his half hour of rest on the journey instead of letting him take it at the docks whilst the vehicle was being loaded.

To straighten this difficulty I thought that I could perhaps make some of the lorries run a second journey with a spare driver. There would be no mate, but an extra man on the loading and unloading gangs. That brought about the conditions I haw set out in Fig. 2.

Two vehicles, Nos. I and 2, leave the mill at 6 a.m, to arrive at the docks at 8 a.m, when loading commences. Another, No. 3, starts from the mill at 7 a.m, and another follows at 8 a.m. In that way I will be getting over my diffieulty of giving each driver half-an-hour's rest at the docks without unduly upsetting the arrangements for loading.

At 11 a.m. another couple of lorries are sent out from the mill, Nos. 5 and 6, and these arrive at the docks at 1 p.m., when work starts after the dinner hour.

Vehicles Nos. I, 2, 3 and 4 get hack to the mill with their loads about noon, 1 p.m. and 2 p.m., so that Nos. 1 and 2

ought to be unloaded and ready for another journey by 1 p.m. I put a spare driver on each of these two vehicles and send them off in time to reach the docks at 3 p.m., to be unloaded by 5 p.m. when the docks close. They get back to the mill at 7 p.m. and there is, of course, no difficulty in unloading them there. Now I have managed to have the 100 tons a day carried using six vehicles with a couple of spare drivers for two of them.

For the sake of simplicity in ascertaining the cost of his transport, I will leave out the Saturday work andconfine myself to the five full days from Monday to Friday inclusive. Lorries Nos. 1 and 2 each do two journeys per day, that is 120 miles, or 600 miles per week. The cost per week according to "The. Commercial Motor" Tables of Operating Costs is approximitely £32 each, £64 for both.

The other four vehicles do only one journey per day each, which is 60 miles, so that their weekly mileage is only 300 per vehicle and the cost per week, according to the same authority, is £23, giving £92 for the four.

Principal Objection

Next I must make allowance for the wages of the two spare drivers, a further 112 per week. I allow £20 per week for overheads and £5 per week on account of the expense of keeping a spare vehicle.

On the assumption that the drivers help with the loading and unloading, I need only 10 men, five at each end to cope with this 100 tons per day. Allowing £5 per week each, that is £50, and my total is £243 per week, which is nearly 9s. 9d. per ton.

The principal objection to this plan is, of course, the need for six vehicles whereas it would seem that four would be sufficient. Possibly the more extensive use of spare drivers

would help, but there is the difficulty that each driver would be employed for only 7 hrs., per day and although, of course, he would be paid for the full 8 hrs., even that rate of pay is not looked upon with favour by lorry drivers to-day.

I next turned to search for vehicles alternative to the maximum-load six-wheelers. The alternative is perhaps obvious articulated six-wheelers with detachable trailers having the same capacity as the maximum-load six-wheelers, namely; 121 tons. It seemed to me that it might be able to carry 100 tons per day using only four of these outfits, and in the upshot I found that practicable, although again not without the use of spare drivers. I have attempted to 'show how this scheme worked in Fig. 3. Tractors Nos. I and 2 with Nos. 1 and 2 trailers leave the mill at 6 a.m. and arrive at the docks a few minates before 8 a.m., giving time to put the trailers in position for loading The Nos. I and 2 tractors then leave to arrive at the mill at 10 a.m. in time to pick up two more empty trailers.

Two more tractors, Nos. 3 and 4 with Nos. 3 and 4 trailers, leave the mill at 8 a.m. and arrive at the docks just before 10 a.m. where they pick up full trailers Nos. 1 and 2, leaving empty trailers Nos. 3 and 4 behind for loading.

Meantime, tractors Nos. 1 and 2 have picked up two additional trailers. Nos. 5 and 6, empty at the mill. They do not leave until Ii a.m. as there is no point in their starting their journey before that because if they did they would arrive at the docks while the dinner hour was in progress. These two tractots, Nos. 1 and 2, pick up Nos. 3 and 4 trailers, now fully loaded, and bring them back to the mill. They drop them there and pick up two more trailers, Nos. 7 and 8. As the drivers of Nos. I and 2 tractors have by 3 pan. completed 81-hours' work and cannot make another journey out and home without exceeding the 1i-hour maximum, we have to put two spare drivers on to these machines in order to do this last jeurney of the day:

Extra Driver The rest of the story can, I think, be appreciated without further exp'anation, by reference to Fig. 3. Tractors Nos. 1 and 2 make three round trips per day, which is 180 miles., so that in five days each of them covers 900 miles. In order to do that, however, we have to hear the cost of -an extra driver on each of these machines for half a day. Tractors Nos. 3 and 4 do only two journeys each day, which is 120 miles or 600 per week.

The cost of operating tractors Nos. 1 and 2 for 900 miles per week, including some provision for the additional cost of the spare trailers, will approximate to £38 per week, that is £76 for the two. Allowing a further £6 for the pay of the spare drivers, tractors Nos. 3 and 4 will cover the 600 miles per week each at a cost of £32, that is £64 for the two. I allow £5 for the cost of maintairkirg a spare vehicle, £20 for overheads, and £60 for the pay of 12 labourers. (Obviously no assistance from titsdrivers can be expected as they are continuously driving.) The total is £231, which is approximately 9s. 3d. per ton.

There are many alternative ways of doing the work and I should appreciate readers' suggestions.—S.T.R.