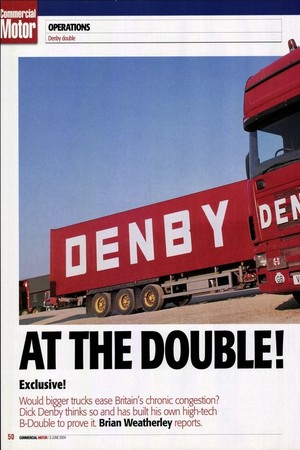

AT THE DOUBLE!

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Exclusive!

Would bigger trucks ease Britain's chronic congestion? Dick Denby thinks so and has built his own high-tech

B-Double to prove it. Brian Weatherley reports.

According to Dick Denby the root problem with congestion is that "we're spending billions of pounds on trunk roads and motorways — and we're not really getting full value for our money". He's got a point. But it's hard for Britain's operators when their trucks are competing for road space with up to 29.3 million cars each day.

According to Dick Denby the root problem with congestion is that "we're spending billions of pounds on trunk roads and motorways — and we're not really getting full value for our money". He's got a point. But it's hard for Britain's operators when their trucks are competing for road space with up to 29.3 million cars each day.

According to Dick Denby the root problem with congestion is that "we're spending billions of pounds on trunk roads and motorways — and we're not really getting full value for our money". He's got a point. But it's hard for Britain's operators when their trucks are competing for road space with up to 29.3 million cars each day. Now the high-profile Lincohishire-based operator is offering a radical solution to the problem: use heavier but, more importantly, longer, top-weight trucks in order to make the best use of the available road space. Specifically,Denby has developed his own prototype "Eco-Link" combination, based on the

Australian B-double concept, but specifically tailored to meet UK conditions, including the need for good manoeuvrability.

An Aussie B-double wouldn't meet the current EU rules, which require a heavy truck to negotiate a "turning corridor" with an inner and outer radius of 5.3m and 12.5m. But Denby's rig does, thanks to an innovative electro hydraulic command-steer system on the shorter "A" trailer's two axles.

An Aussie B-double wouldn't meet the current EU rules, which require a heavy truck to negotiate a "turning corridor" with an inner and outer radius of 5.3m and 12.5m. But Denby's rig does, thanks to an innovative electro hydraulic command-steer system on the shorter "A" trailer's two axles.

An Aussie B-double wouldn't meet the current EU rules, which require a heavy truck to negotiate a "turning corridor" with an inner and outer radius of 5.3m and 12.5m. But Denby's rig does, thanks to an innovative electro hydraulic command-steer system on the shorter "A" trailer's two axles. But why a B-double? "We couldn't go higher or wider because of the existing EU limits," Denby explains."I felt that the only

way we could go was to grow longer and put another bend in it —but we had to make it go around a corner just like a standard vehicle." To achieve that goal Denby looked for an engineer to help him make his dream double a reality. Step forward Jack Goodwins, former chief development engineer at Crane Fruehauf and now a consultant with a wealth of experience on trailer design and tricky P

turning-circle problems. Goodwin's answer was to develop a unique command steered system. Up front the tractor retains a conventional fifth wheel. However, linked to it on the first trailer is a special front coupling mounted on a rotating turntable sitting above the A The steering bogie on the short "A" trailer is capable of handling 18-tonne loads, running on 445/45R 19.5in wheels tractor bogie. Within that second coupling's jaws (and in constant reaches 17° — although further yaw is obtained contact with them) sits a wedge bolted to the beyond 17°, it does not result in any further

rubbing plate. steering at the trailers' axles. As the tractor turns, or "yaws" as Goodwins The upshot is that they track the tractive describes it, the wedge senses the turning unit's turning motion perfectly, keeping the

motion and sends a signal down to the two whole outfit inside the EU turning circle limit. SAF stub steering axles (provided by IMS) At speeds above 40km/h and when reversing

which are operated by rams driven from a hythe steering axles lock dead ahead.

draulic powerpack mounted under the chassis. The front axle steers to a maximum of 24.5° Experimental unit while the trailing axle steers to 32°. As soon as The short "A" trailer currently weighs around the tractor starts to turn both axles follow suit, seven tonnes but Goodwins stresses that it is stopping only when the tractor's yaw angle an experimental unit and that a production Goodwin's answer was to develop a unique command steered system. Up front the tractor retains a conventional fifth wheel. However, linked to it on the first trailer is a special front coupling mounted on a rotating turntable sitting above the A The steering bogie on the short "A" trailer is capable of handling 18-tonne loads, running on 445/45R 19.5in wheels tractor bogie. Within that second coupling's jaws (and in constant reaches 17° — although further yaw is obtained contact with them) sits a wedge bolted to the beyond 17°, it does not result in any further

rubbing plate. steering at the trailers' axles. As the tractor turns, or "yaws" as Goodwins The upshot is that they track the tractive describes it, the wedge senses the turning unit's turning motion perfectly, keeping the

motion and sends a signal down to the two whole outfit inside the EU turning circle limit. SAF stub steering axles (provided by IMS) At speeds above 40km/h and when reversing

which are operated by rams driven from a hythe steering axles lock dead ahead.

The front axle steers to a maximum of 24.5° Experimental unit

The front axle steers to a maximum of 24.5° Experimental unit while the trailing axle steers to 32°. As soon as The short "A" trailer currently weighs around the tractor starts to turn both axles follow suit, seven tonnes but Goodwins stresses that it is stopping only when the tractor's yaw angle an experimental unit and that a production

model would be lighter.The unit itself was built by Slemish Trailer, of Ballymena, and has a 7.0m Boalloy body.

It features a 1,805mm axle spread capable of handling 18-tonne loads running on 445/45R 19.5in wheels and tyres.The overall length of the rig is just over 25m with the second 13.6m "B" trailer connected to the "A" trailer by a conventional fixed fifth wheel over the "A" trailer's steering bogie.

Scania also played a part in creating the Eco-Link unit. Technical manager Clive Burnet says: "Dick started talking to me about this a couple of years ago and we put some drawings together on our computer system looking at possible concepts." Throughout the vehicle's development Burnet has continued to take an interest in the project, advising on suitable power-toweight ratios and tractor specifications.

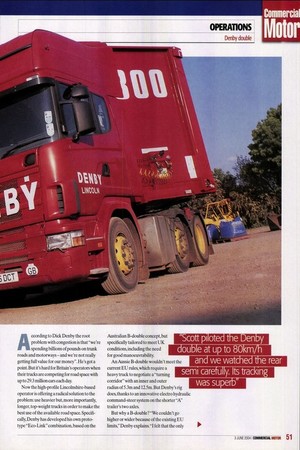

Although the first "official viewing" of Dick Denby's B-double won't be until the forthcoming BTAC trials at MIRA this weekend, Commercial Motor recently had an exclusive first drive of the R124.420 Scania-powered rig at the Qinetiq test track in Chertsey, Surrey, home of the tipper tilt table and the normal venue for CM light van tests. Although unladen, with a kerbweight of around 20 tonnes it provided us with a useful feel. Initially we did a lap in the passenger seat watching while the steering was handled by Angus Scott, one of Denby's senior drivers, who had already driven the B-double."I've

been practising quite a bit on a very restricted area," he told us. "We've got a warehouse on an airfield at Ingham in Lincolnshire where we've been able to get a feel for it."

We were interested to see what Scott, with his 20 years' experience driving artics, made of it. His reply was illuminating: "I was a bit sceptical at first but after having driven it I can't believe it — it's so impressive. You could easily forget the extra trailer the way it follows."

This didn't sound to us like a normal Bdouble. CM has driven them in Australia and Scandinavia and found that the rear trailer can "wag" somewhat, with even the smallest steering input being magnified as it travels down the 25m rig.

Perfect tracking

However, we were in for a surprise. While Scott piloted the Denby double around the track at speeds up to 801un/h we watched the movement of the rear semi carefully in the mirrors. Its tracking was superb. Whether that's down to the bogie position or coupling position on the A-trailer bogie we can't say. Whatever the reason the rear trailer followed the first beautifully and it's worth remembering that above 40km/h the steering bogie is locked in the dead-ahead position.

We then took the wheel.The natural reaction with double-trailer rigs is normally to over-compensate and take enormous wide swings.With the steering bogie on the A-trailer you don't need to, and exiting the track marshalling area through a mini chicane of crash barriers proved no problem. Out on the main circuit the unladen rig accelerated smoothly, but what really stood out was how well it held the line out on the track — hitting the banked section at 801un/h-plus it ran perfectly true with the second "B" trailer, resisting the temptation to drop down off the curve.Then it was time to take it through the "snake" section of the Qinetiq test track

— appropriately named as it has four nasty adverse-camber turns and a vicious hairpin that can bite the unwary as well as a very nasty hill in the middle.

We first watched from the passenger side while Scott took it through the snake. With all those attic years under his belt he clearly wasn't phased by the B-double's extra overall length as he powered the big rig through the twisting section with great aplomb.

Mindful of Denby's undisclosed investment we took it just a little slower! But on both runs we were again impressed by the trailer tracking and handling. Scott told us: "I'd love to get it out on the road — that's the only way to try it." And if he was given that chance? "I'd be off with it like a shot!"

We next moved on to the Qinetiq steering pad, which has a number of concentric circles painted on it, to see just how tight the Denby double could be turned without cutting across the marked lanes. Bit by bit we gradually moved into ever tighter turning corridors with the rearmost trailer following on perfectly, thanks to the turning axles on the short A-trailer. However, what you don't see from the driver's seat as you watch for the trailer cut-in is the "cut-out" of the rear of the first trailer which is hidden from the normal vision of the mirrors.Watching from the outside as the vehicle turned we did rather notice the rear bogie sticking out which makes us think that "Caution this truck makes wide turns" stickers wouldn't be inappropriate on either side. That said, we've no reason to doubt the claims that the whole outfit can meet the current 12.5m (outer) and 53m (inner) turning "corri

dor" required under EU regs for all top-weight trucks. Scania's Burnet says putting cameras on the top front corner of the first trailer to watch that cut-out would be a useful addition and aid the driver by removing the blind spots.

Finally, we had a go reversing the Denby double both in a straight line and around a corner. With only a limited time on the rig Scott seemed nonplussed by it, but after a few shunts he managed both manoeuvres which is more than can be said for CM'S driver! The secret is to get the first trailer to kick over the second, then keep steering wheel movements to a minimum to prevent the outfit kinking — which is easier said than done. However, Scott reckons that with practice it would not present a problem: "I'm sweating but if you did this all the time you'd soon get the hang of it."

Whether the Great British Public will get the hang of a B-double on British roads remains an open question, but Denby stresses that the argument for longer rigs must be based on the potential environmental benefits, not least in terms of the reduced tonne/km emissions argument. He also sees the ability to drop one trailer and proceed into an urban area with a shorter A-trailer as a good route to maximising vehicle flexibility.

Environmental benefits

The bonus for congestion would also be significant:"Based on 40m [separation] between vehicles, two Eco-Link vehicles would take up 130m of highway whereas three current attics take up 170m." Whether the public will buy that is debateable, which is why CM will be reporting on Denby's double over the coming weeks, bringing you reaction to it from operators, politicians and potential customers. Eventually Denby says he'd like to gain a permit to use his double on normal roads: "But that's some way ahead. We've still got to do stability and braking tests as well as driver vision." Meanwhile, if it's going to take a radical solution to solve congestion, Denby is more than happy to champion his cause — at the double.m