"ROUGHIN( " with a Four-whee /e Tractor

Page 18

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

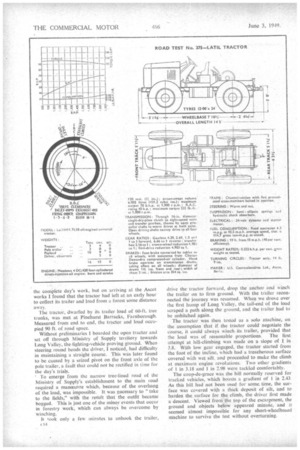

THERE were many occasions when the Latil fourwheel-drive tractor was ploughing through mud and water, above axle level, while I tested it over the Tank proving ground at Farnborough. During these tests it climbed a loose-surfaced gradient of 1 in, 2.43, forded ditches which were filled with liquid mud, and winched its loaded trailer from soft ground.

I had arranged for the tractor to haul its load over the quagmire, but, on seeing the 38-ft. . overhang of timber on the trailer, I decided that it would be impossible to take the complete unit through the ditches The payload consisted of six newly felled Scotch fir tree trunks, the longest of which was 60 ft. Altogether theve were 390 cubic ft. of timber on the trailer, each cubic foot weighing approximately 60 lb.

Meadows Oil Engine As manufactured in this country, the Latil is equipped with a Meadows four-cylindered direct-injection engine, which, with a " square " bore and stroke of 130 mm., develops 75 b.b.p. at its governed speed. It is derated to 70 h.p. when fitted to the tractor. Like other power units of the Meadows DC range, the four-cylindered version employs toroidal-cavity pistons, precisionfinished thin-shell bearings and C.A.V. four-spray injec

tors. Timing gears are arranged at the rear of the cast-iron crankcase and cylinder block. injector timing is controlled by a Meadows automatic-advance governor.

Straight-toothed gears are employed in the eight-speed main and transfer gearbox, the ratios providing a speed range from li m.p.h. to 244 m.p.h. Each end of the gearbox output shaft is connected to the front or rear axle, the tractor being permanently engaged in fourwheel drive.

Simple load-carrying beams are used for both axles. Drive from the gearbox is transmitted through overhead differentials secured to the chassis frame, and independent mechanically jointed tubular shafts to straighttoothed pinions, engaging in internal hub assemblies. at the wheels. This arrangement gives double-reduction gearing to both axles. Levers in the cab are connected to the differential assemblies to lock the drive as required.

Air Brakes

A Clayton-Dewandre engine-driven two-cylindered 10-cubic-ft. compressor supplies air to a reservoir, which.

in turn, is piped to the foot-brake control valve. A single air-pressure operating cylinder, connected to a cross-shaft, operates the brakes at all four wheels. The hand brake is linked to internal-expanding shoes in an enclosed brake drum attached to the rear propeller'shaft and takes effect on all wheels.

In forestry work, and occasionally in road operation. manoevrability is a vital factor. In the Latil tractor it is increased by a four-wheel-steering arrangement. The steering drop arm is connected to the stub assemblies of both axles, and the tractor has a turning circle of 15 ft. The rear stub axles are locked in position for normal driving.

The conventional semi-elliptic springs have fixed and sliding ends to give progressive action when operating over rough ground. Rotary hydraulic shock absorbers are fitted to both axles.

Serving the dual role of road or cross-country prime mover, the Latil is also equipped with a winch for forestry operation. The winch, driven from the rear of the gearbox, may be operated in any of the eight ratios of the gearbox. Reduction gearing for the winch is self-contained on the unit, and a maximum pull of 11,000 lb. in bottom gear is available. _ .

l had intended to make a fuel-consumption trial over c12 the complete day's work, but on arriving at the Ascot works I found that the tractor had left at an early hour to collect its trailer and load from a forest some distance away.

The tractor, dwarfed by its trailer load of 60-ft. tree trunks, was met at Pinehurst Barracks, Farnborough. Measured from end to end, the tractor and load occupied 90 ft. of road space.

Without preliminaries 1 boarded the open tractor and set off through Ministry of Supply territory towards Long Valley, the-fighting-vehicle proving ground. When steering round bends the driver, I noticed, had difficulty in maintaining a straight course. This was later found to be caused by a seized pivot on the front axle of the pole trailer, a,fault that could not he rectified in time for the day's trials.

' To emerge from the narrow tree-lined road of the Ministry of Supply's establishment to the main road required a manceuvre which, because of the overhang of the load, was impossible. It was necessary to "take to the fields," with the reSult that the outfit became bogged. This is just one of the minor events that occur in forestry work, which can always be overcome by winching.

Ii took only a few minutes to unhook the trailer,

drive the tractor forward, drop the anchor and winch the trailer on to firm ground. With the trailer reconnected the journey was resumed. When we drove over the first hump of Long Valley, the tail-end of the load. scraped a path along the ground, and the trailer had to be unhitched again.

The tractor was then tested as a solo machine, on the assumption that if the tractor could negotiate the course, it could always winch its trailer, provided that

the load was of reasonable proportions. The first attempt at hill-climbing was made on a slope of I in 3.8. With low gear engaged, the tractor started from the foot of the incline, which had a treacherous surface covered with wet silt, and proceeded to make the climb. at maximum engine revolutions. Two other gradients of 1 in 3.18 and 1 in 2.98 were tackled comfortably.

The coup-de-grace-was the hill normally reserved for tracked vehicles, which boasts a gradient of I in 2.43. As this hill had not been used for some, time, the surface was covered with a thick deposit of silt, and to harden the surface for the climb, the driver first made a descent. Viewed from the top of the escarpment, the ground and objects below appeared minute,and it seemed almost impossible for any short-whcelbased

machine to survive the test without overturning. •

With low gear engaged, and brakes lightly applied, the descent was made unhurriedly. To retain my balance I braced both feet against the top of the scuttle, whilst the driver pushed with determination against the steering wheel. Keeping a straight course, the Latil eventually reached the foot of the gradient without incident.

Then came the task of climbing back to the top. Again with low gear engaged, maximum engine revolutions were reached at the base of the slope, and I prepared to lock both,differentials at the first sign of wheel spin. The engine revolutions fell slightly, but there was plenty of reserve power and the tractor continued to climb steadily and without wheel spin. Nevertheless, after reaching the top and descending the hill, I was relieved to be on level ground again.

Driving Over Gullies The next part of the trials comprised a short run over rough ground, with numerous gullies, to test the steering and suspension. Despite rough treatment, the Latil survived the course without breakage.

I then took the tractor over the Tank proving ground which, at the time, was a sea of mud covering the deep furrows and craters hidden below. Throwing up showers of mud and water from all wheels, the Latil ploughed through the quagmire, the axles frequently being below the level of the liquid. It was an arduous test for the machine—and the crew. We emerged after a stiff 20-minute battle, covered with mud but otherwise undamaged.

When the trailer had been connected to the tractor, the unit was driven to the adjoining main road for an immediate test of the brakes. Considering the nature of the load and the amount of mud and water that could. have entered the brake equipment, the stopping distance of 19 ft. from 15 m.p.h. without wheel locking shows that the system was amply efficient

A fuel test was made after the small supply tank had been connected to the fuel-injection pump. Having set the stop watch, I drove from Farnborough towards Bagshot and Ascot. When descending inclines, I found that a light pressure on the brake pedal applied the brakes on the trailer and prevented the load from over-running the prime mover. The trailer brakes are operated in the initial movement of the pedal and further depression brings the tractor brakes into use This is a safety measure which ensures that a unit will not jackknife when braking.

On level ground, the tractor and load could be driven at a steady 15-16 m.p.h. without wandering and this speed was maintained for The major part of the course. Uphill gradients brought the speed down to 8-12 m.p.h., according to their severity. Gears were changed silently by double-declutching, with only a brief pause in neutral.

Fuel Consumption 6.2 m.p.g.

At the end of six miles, the fuel in the tank was almost exhausted, and the test was concluded at this point to check the consumption and average speed. The consumption rate was 6.2 m.p.g. and the average speed, 10.5 m.p.h. The radiator temperature remained at 152 degrees F. throughout the test, ambient being 50 degrees F. There was no evidence of overheating during any part of the day's trials.

A sharp turn into the timber yard at the end of the trials required the use of the four-wheel steering to manceuvre the load through the entrance and under a crane. I left the Latil convinced that four-wheel steering in a forestry tractor' is not a luxury. but almost a necessity.