HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

525.—Improving the Clutch Centre Cap on a Tylor Engine.

A suggestion for improving the clutch centre cap on a Tylor engine, which has already been put into practice with successful results, is forwarded to us by a correspondent. He points out that there has often been a considerable amount of inconvenience as well as delay with this cap when removing it, and in some cases it has worked loose on the drive shaft, The present design has a grub screw, and when an attempt is made to unscrew this, in many cases, the top breaks away, and the only method of removing the screw then is to drill it out. In order to avoid such trouble the grub screw may be replaced by a hexagon-headed setscrew, that portion of the cap in which the setscrew is fitted being filed or otherwise cut down so that the head of the screw does not protrude above the level of the remainder of the cap. When necessary this screw can easily be removed by the use of a spanner.

526.—Replacing a Worn Commutator.

If a dynamo has been neglected for any considerable period it will probably be found that the commutator is black and scored in places. To repair the damage it will be necessary to re-turn it. To effect this the armature should be removed and the spindle carefully centred so that the journals run perfectly true.

The truing of the commutator is done in the following manner. A high speed should be employed and light cuts taken with a turning tool which has no lip. Sand-paper may then be applied for obtaining a good finish.

Sometimes it is also necessary to renew the dynamo brushes. It is important that they should bed properly on the commutator. Therefore, when renewing them, they should be filed on the wearing surfabe to approximately the same radius as the commutator, and after being placed in the holders and the springs adjusted to give light pressure, a strip of medium glass-paper can be introduced between them and the commutator, this paper being pulled backwards and forwards with the rough side against the brushes, so that the exact radius is given to their faces. B44 Care should also be taken to see that the brushes are quite free in their holders, as neglect of this simple precaution may result in severe sparking, and, of course, all grit should be carefully cleaned off.

527.—Removing the Brake-shoe Pins of the 15-ter Fiat.

We were recently asked to give advice as to a method of removing the transmission brake-shoe pins on the model 15-ter Fiat, and as we ourselves were not cognizant with the method, Fiat Motors, Ltd., have kindly recommended the following procedure.

First disconnect the foot-brake rod, then unbolt the brakes on the gearbox which support the brake cross-shaft. Lift off the brakes and cross-shaft complete. Remove the nuts from the brake pins and draw off the brake bands, and the brake pins may then be easily removed.,

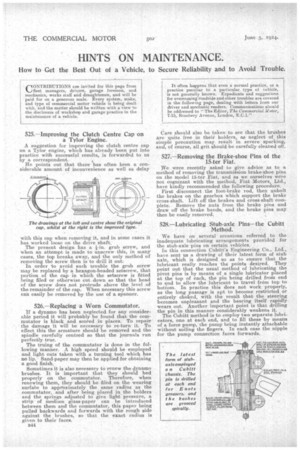

528.—Lubricating Stub-axle Pins—the Cubitt Method.

We have on several occasions referred to the inadequate lubricating arrangements provided for the stab-axle -pins on certain vehicles.

In this connection Cubitt's Engineering Co., Ltd., have sent us a drawing of their latest form of stub axle? which is designed so as to ensure that the lubricant really reaches the points desired. They point out that the usual method of lubricating the pivot pins is by means of a single lubricator placed at the top of each, the pin being drilled from end to end to allow the lubricant to travel frdm top to bottom. In practice this does not work properly, as the long passage is apt to become restricted or entirely choked, with the result that the steering becomes unpleasant and the bearing itself rapidly wears out. Another important point is that drilling the pin in this manner considerably weakens it.

The Cubitt method is to employ two separate lubricators, one at each end, and to fill these by means of a force pump, the pump being instantly attachable without soiling the fingers. In each case the nipple for the pump connection faces forwards.