For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

• A PliIZE OF TEN SlilLLINGS is awarded each week to the sender of the best letter which we publish on this page ; all otherz are pai‘for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith, Address, D., M. and F., "The Commercial Motor," 7-15. Bosebery Avenue, London; E.G. 1.

Lamps Alight.

On Saturday, June 7th, light your lamps at 9.40 in London, 10.49 in Edinburgh, 10.6 in Newcastle., 10.3 in Liverpool, 9.54 in Birmingham, 9.50 in Bristol, and 19.46 in Dublin.

An Extra Air Inlet.

The sender of the following eommunieation: has been awarded the 10s. prize this week.

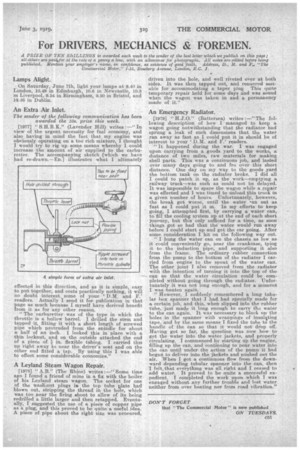

[1977] " S.H.B.K." (Lavender Hill) write,s:—" Iii view of the urgent necessity for fuel economy, and also having in mind the fact that my engine was obviously operating on a too rich mixture, I thought I would try to rig up some means whereby I could increase the amount of air • supplied to the carburetter. The accompanying sketch (which we have had re-drawn.---En.] illustrates what I ultimately effected in this direction, and as it is simple, easy to put together, and costs practically nothing, it will no doubt interest some of your 1/M, and F.' readers. Actually I send it for publication in that page as much because I myself have derived benefit from it as for any other reason. " The carburetter was of the type in which the throttle is a hollow barrel. I drilled the stem and tapped it, fitting it with a short length of screwed pipe which protruded from the spindle for about a hall of an inch. I locked this in place with a thin locknut, and on the outside attached the end of a piece of in. flexible tubing. I carried this up right away to near the driver's seat and on the other end fitted a tap. 13y using this I was able to effect some considerable economies."

A Leyland Steam Wagon Repair.

119781 " A.B." (The Rhine) writes :—" Some time ago I found a friend of mine in a fix with the boiler of his Leyland steam wagon. The socket for one of the wash-ont plugs in the top tube plate had blown out, stripping the thread in the hole, which was too near the firing shoot to allow of its being redrilled a little larger and then retapped. Eventually, I suggested the use of a piece of copper pipe as a plug, and this proved to be quite a useful idea. A piece of pipe about the right size was procured,

driven into the hole' and well riveted over at both sides. It was then tapped out, and renuered suitable for accommodating a taper plug This quite temporary repair held for some days and was sound when the wagon was taken in and a permanency made of it."

An Emergency Radiator.

[1979] " (Battersea) writes :—"The fol lowing description of how I managed to keep a wagon going notwithstanding that the radiator had sprung a leak of such dimensions that the water ran away as fast as I could put it in should be of interest to your D.M. and F.' readers.

"It happened during the war. I was engaged upon carrying from a goods yard to the works, a distance of two miles, raw materials for making shell parts. This was a continuous job, and lasted over many days going to and fro overthis short distance. One day on my way to the goods .yard the bottom tank on the radiator broke. I did all I could to patch it up, as the work—emptying a railway truck—was such as could not be delayed. It was impossible to spare the wagon while a repair was effected and I was timed to unload this truck in a given number of hours. Unfortunately, however, the break got worse, until the water an out as fast as I could put it in. In my efforts to keep going, I attempted first, by carrying a water can, to-fill the cooling system up at the end of each short journey, but this only sufficed for a time, as soon things got so bad that the water would run away before I could start up and get the car going. After some consideration I hit on the following way out.

"I hung the water can on the chassis as low as it could conveniently go, near the crankcase, tying it to the induction pipe, and supporting it also from the frame„ The ordinary rubber connection from the pump. to the bottom of the radiator I carried from engine to the spout of the water can. The other joint I also removed from the radiator with the intention of turning it into the top of the can so that the water circulation could be completed without going through the radiator. Unfortunately it was not long enough, and for a moment I was beaten again.

"However, I suddenly remembered a long tubular box spanner that I had had specially made for a certain job, and this, when slipped into the rubber tube, just made it long, enough to carry the water to the can again. It was necessary to block up the holes in the spanner with wrappings of insulting tape, and by the same means I fixed the tube to the handle of the can so that it would not diop off. Having got so far, the question was now how to get the water into the water jackets, and properly circulating. I commenced by starting up the engine, filling up the can, and continuing to pour water into the can until under the action of the pumn it had begun to deliver into the jackets and pushed oot the air. When I got a continuous flow from the downward depending tubular spanner into the can, then "I felt that everything was all right and I ceased to add water. It proved to be unite a successful expedient. I completed the work upon which I was enzaged without any further trouble and lost water neither from over beating nor from road vibration."