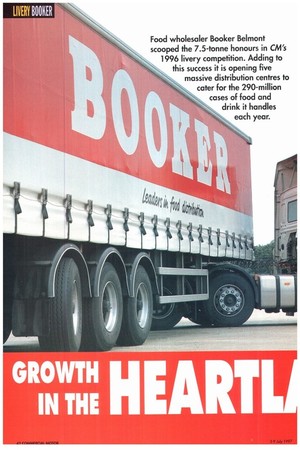

Food wholesaler Booker Belmont scooped the 7.5-tonne honours in CM'S

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

1996 livery competition. Adding to this success it is opening five massive distribution centres to cater for the 290-million

cases of food and N drink it handles each year.

PHOTOGRAPHY by TOM LEE

Image is particularly important in the food industry: Booker Belmont Wholesale won the 7.5-tonne class in last year's Commercial Motor Livery Competition with a simple scheme that

looked clean and hygienic. BBW transport manager Ken Needham says that image and public perception should be important to everyone in the road transport industry. He regrets that so few operators seem to realise this or do much about it.

BBW is as big as any of the three leading supermarket chains—it handles some 290million cases of food and drink a year, representing more than 20,000 product lines. The company is part of the Booker group and is a direct supplier to Booker Wholesale Foods and Booker Cash & Carry.

04 At present BBW is going through a Ll(X)m redevelopment, known as the Heartlands . t•, project, which involves the creation of

:-. five regional distribution centres .... (RUCs). So far two of them are on , ... line: the Scottish RDC at Living

ston, covering 23,000m2, and the North-West RDC at Haydock, covering 39,000m2. Both are run by contractors but the next two RDCs will be managed by Booker itself. They're at Hatfield (39,000m2 opening in September) and Bristol (37,000m2 opening in October). A fifth site, in the Northampton area, is due to open next spring.

The decision to go to RDCs was made in January 1995; implementation was delayed by Booker's acquisition late last year of rival cash & carry operator Nurdin & Peacock, which has boosted the company's throughput by around 60%.

BBW buys its own trucks and trailers—even when contractors are used, they operate BBW vehicles. Needham says this gives greater flexibility: "If operating needs at one or all depots change there will be no problems in moving vehicles."

Most RDCs have, or will have, their own maintenance units, built to BBW specification but run by franchised dealers on its behalf. This allows the company to control the standard of maintenance. "Repair it properly, repair it once" is the aim: effective maintenance is the number one issue, says Needham, with cost a secondary consideration.

The bulk of the BBW fleet is Mercedes-Benz and Volvo, with some Scanias, and as far as possible each RDC is serviced by a single marque. Just ordered, at a total cost of £4.8m, are 33 Mercedes-Benz 6x2 Actros tractors and 49 semi-trailers (21 Lawrence David curtainsiders and 28 Schmitz multi-temperature units).

The multi-temperature trailers will have the latest ThermoKing SMX fridges which are quiet and use an environmentally friendly refrigerant. Moveable GRP bulkheads with flexible side seals and a three-evaporator system permit any combination of frozen, chilled and ambient loads.

Flexibility

When carrying goods for BBW the curtain. siders are invariably loaded and unloaded through the rear doors, but they were specified for their flexibility. On return runs from RDCs, for example, they might be collecting from suppliers who want to load through the sides. Backloading "has tremendous potential" says Needham; he sees the day when trans-shipment could be as important as primary distribution with the movement of loads between RDCs. Vehicles are double-shifted and cover up to 140,000 miles a year. They generally leave RDCs between 06:00-07:00hrs, with a second run in the afternoon, and possibly a third trip later in the day.

The second and third runs are the ones which might carry consignments from suppliers back to the RDCs. This should be relatively easy to control when the entire fleet is fitted with TARDIS (Tracking and Real Time Data Information System). TARDIS provides the base depot with an up-to-date display of the position of every vehicle; drivers can commu

nicate with the transport office using one of 96 pre-programmed me&sages. Another modern system used by BBW is Trace, the fuel system monitoring software from MIS. Drivers at the RDCs are issued with vehiclebased fuel keys and their own PIN numbers to identify vehicles and themselves at the fuel pumps and vehicle washers.

Autodialling

The system is held on a PC at BBW's Wellingborough headquarters: it collects relevant information by autodialling all depots for data at midnight.

The system measures fuel consumption to two decimal points and shows if drivers have used duty-paid diesel instead of duty-free gas oil for the fridge motors. Trace is generally being introduced with new vehicles so that drivers will not feel unfairly treated. At current prices even a saving of 0.05mpg translates to a reduction of 07,500 in the fleet's fuel bill. Other innovations that are saving money include the use of third tractor axles that steer or track: these can virtually double tyre life. BBW is now trying wide-single tyres on the front axles of its tractors and hopes to improve tyre life by up to 40%.

When all RDCs are up and running the average stockholdings should come down to around a week's consumption. In the past it has been as high as eight weeks. And just to show that nothing stays still, there's even a new livery, which will be applied to all 2,000 vehicles in the Booker fleets, including BBW's. It will be interesting to see if it can improve on last year's prize winner.

by John Aldridge