NAVISTAR AND THE SPLIT SHOT APPROACH

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

A'though not available in Europe, some of Navistar's latest projects are likely to affect engine designs on both sides of the Atlantic.

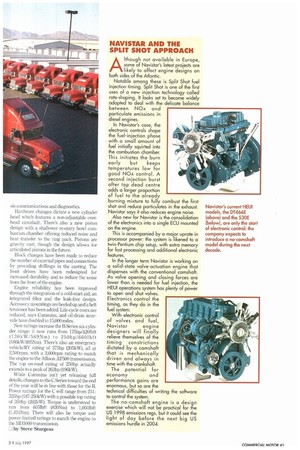

Notable among these is Split Shot fuel injection timing. Split Shot is one of the first uses of a new injection technology called rate-shaping. It looks set to become widely adopted to deal with the delicate balance between NOx and particulate emissions in diesel engines. In Navistar's case, the electronic controls shape the fuel-injection phase with a small amount of fuel initially squirted into the combustion chamber. This initiates the burn early but keeps temperatures low for good NOx control. A second injection burst after top dead centre adds a larger proportion of fuel to the already burning mixture to fully combust the first shot and reduce particulates in the exhaust. Navistar says it also reduces engine noise. Also new for Navistar is the consolidation of the electronics into a single ECU mounted on the engine.

This is accompanied by a major uprate in processor power: the system is likened to a twin-Pentium chip setup, with extra memory for fast processing and additional electronic features.

In the longer term Navistar is working on a solid-state valve-actuation engine that dispenses with the conventional camshaft. As valve opening and closing forces are lower than is needed for fuel injection, the HEUI operations system has plenty of power to open and shut valves. Electronics control the timing, as they do in the fuel system.

With electronic control of valves and fuel, Navistar engine designers will finally relieve themselves of the timing constrictions dictated by a camshaft that is mechanically driven and always in time with the crankshaft.

The potential for economy a nd performance gains are enormous, but so are the technical difficulties of writing the to control the system. The no-camshaft engine is a design exercise which will not be practical for the US 1998 emissions regs, but it could see the light of day before the next big US emissions hurdle in 2004. software