BENT WOOD IN BODY CONSTRUCTION.

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Definite Advantages Offered by Bent in Place of Sawn Timbers where Curves are Introduced in the Design.

IN these days of Mass production and works efficiency it behoves the manufacturer to grasp every opportunity which will increase his production

and reduce his costs. More particularly does this apply if the proposed alteration of the procedure will improve the quality of the finished article, will eliminate waste and enable him to place before his customers, actual and .prospective, a superior article which makes a smaller demand upon the pocket.

There is probably no sphere in which this applies with greater force than in the motor trade. A tour of the works which turn out any of the modern motor coaches, vans and buses is an education in the application of scientific methods of production. The manufacture of the chassis in particular has received such concentrated attention from experts that it can be said to approach perfection.

The methods employed in body construction, how. ever, show greater room for improvement. In spite of numerous more or less successful experiments with metal construction, the principal material used in motor body work, as was said in a recent article in this journal, is till timber. With all its many advantages and disadvantages, timber will probably outlive metal_ as the chief constituent of motor coach work. Some of those disadvantages of timber as a constructional material are its relatively high weight in proportion to its bulk, its liability to alteration under climatic changes if it be not properly seasoned,' and the danger of fracture of short grain when sawn into the sweeps demanded by modern coach wcirk. Hence a factor which will reduce weight, retain its dimensions in the highest possible degree; eliminate short grain and, at the same time, speed up production and reduce weight and waste is the ideal of every body builder. Such a factor is 'found in the employment of bent timber.

Strength and Lightness with Bent Timbers.

The modern motor body must combine comfort, beauty of line and finish with the minimum of Weight and such strength of construction as will guarantee years of service without attention other than occasional repainting. The realization of such requirements is naturally, assisted by the use of bent wood as a framing material.

Up-to-date manufacturers realize this important point, and motor bodies are in service framed entirely of beat timber ; most others contain bent wood according to requirements. The graceful curves which make such a strong appeal to the prospective purchaser, and which unquestionably help to bring custom to the vehicle, are, by the use of bent sweeps, attained without sacrificing strength of construction ; weight is minimized, for a bent sweep, using timber of half the width and thickness, is actually stronger than one that is sawn ; whilst works costs are reduced by the saving of time required for sawing and making of joints, which are essential if the body constructed of sawn sweeps is to stand up to the exacting requirements of modern speeds and road conditions.

For many years the old-time coachbuilder had used bent timber to improve his products; his modern prototype, the motor body builder, follows his lead with advantage to himself and satisfaction to his customer.

The Many Applications of Bentwood in Bodywork.

It is of interest to the practical man to note some of the possibilities of this valuable material in motor body construction. Bentwood hoodsticks have, of course, been employed since the earliest days of motoring, but the more recent introduction has not met with the unqualified approval of the trade, chiefly because of the difficulty which occurs when a repair has to be made. Pillars can be both lightened and strengthened by being bent instead of sawn. Roof sweeps of timber never sag and have not the tendency to crack on the curves to which those sawn out are so prone. Corner framing can be reduced to a minimum weight and joints eliminated by using bends. Cant rails, corners and canopy bows are in daily use in the up-to-date shops. Bucket-seat backs and cushion frames can be bent lighter and stronger than sawn, and the problem of the wheel arch is solved by this method ; in fact, the only practical wheel arch for low-loading chassis work is a bent one. Dash framing sweeps and two-seater boot sweeps are largely employed by mass-production factories.

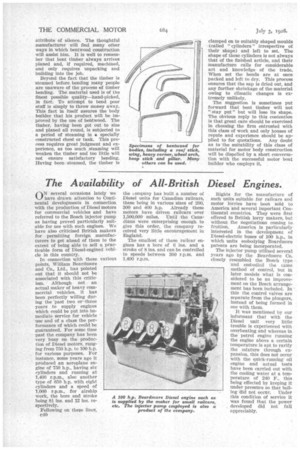

The bentwood wing or mudguard is superseding the steel guard for commercial motors, particularly where exacting road conditions or special loads (as salt, chemicals, etc.) are required. This form of wing is lighter, cheaper and actually stronger than one of light gauge steel and possess, moreover, the golden attribute of silence. The thoughtful manufacturer will find many other ways in which bentwood construction will assist him. It is well to remember that bent timber always arrives planed and, if required, machined, and only requires unpacking and building into the job.

Beyond the fact that the timber is steamed before bending many people are unaware of the process of timber bending. The material used is of tile finest possible quality—hand-picked, in fact. To attempt to bend poor stuff is simply to throw money away. This fact in itself assures the body builder that his product will be improved by the use of bentwood. The timber, having been got out to size and planed all round, is subjected to a period of steaming in a specially constructed chest or tank. This process requires great judgment and experience, as too• much .steaming will weaken the timber and too little will not ensure satisfactory bending. Having been steamed, the timber is

clamped on to suitably shaped moulds (called " cylinders " irrespective of their shape) and left to set. The shape of these cylinders is not always that of the finished article, and their manufacture calls for considerable art and knowledge of the trade. When set the bends are at once• packed and left to dry. This process ensures that the sap is dried out, and any further shrinkage of the material owing to climatic changes is extremely unlikely.

The suggestionis sometimes put forward that bent timber will not "stay put" but will lose its shape. The obvious reply to this contention is that great care should be exercised in choosing the firm entrusted with this class of work and only houses of repute and experience should be applied to for quotations. Any doubt as to-the suitability of this class of material for motor body construction will be dispelled by a short conversation with the successful motor boat builder who employs it.