FLEE T F A V I E

Page 18

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

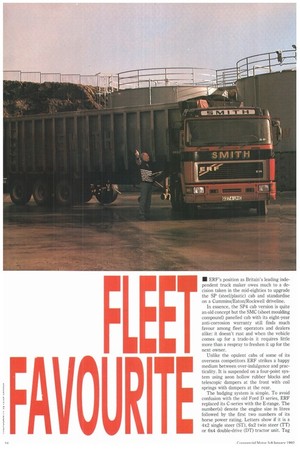

• ERF's position as Britain's leading independent truck maker owes much to a decision taken in the mid-eighties to upgrade the SP (steel/plastic) cab and standardise on a Cummins/Eaton/Rockwell driveline.

In essence, the SP4 cab version is quite an old concept but the SMC (sheet moulding compound) panelled cab with its eight-year anti-corrosion warranty still finds much favour among fleet operators and dealers alike: it doesn't rust and when the vehicle comes up for a trade-in it requires little more than a respray to freshen it up for the next owner.

Unlike the opulent cabs of some of its overseas competitors ERF strikes a happy medium between over-indulgence and practicality. It is suspended on a four-point system using aeon hollow rubber blocks and telescopic dampers at the front with coil springs with dampers at the rear.

The badging system is simple. To avoid confusion with the old Ford D series, ERF replaced its C-series with the E-range. The number(s) denote the engine size in litres followed by the first two numbers of its horse power rating. Letters show if it is a 4x2 single steer (ST), 6x2 twin steer (TT) or 6x4 double-drive (DT) tractor unit. Tag and pusher axled

too 6x2 models are also available (CM2I-27 Nov), ERF competes from 14 tonnes upwards, and offers a choice of day and sleeper cabs across its comprehensive range of 38-tonne tractive units. The market up to the easy-duty end of the 38-tonne class is covered by E8 4x2s with 179 and 250kW (240 and 275hp) options from its Cummins 8.3-litre 6CTAA engine.

For more arduous top-weight operation ERF offers three ranges: the EIO with the Cummins 10-litre engine at 186, 205 and 242kW (250, 275 and 325hp); the recent E12 with its 12.17-litre Perkins Tx at 239, 276 and 298kW (325, 375 and 400hp); and the E14.

This has the range of charge-cooled 14litre Cummins NTE engines which ERF offers in four ratings, producing 239, 272, 306 and 347kW (320, 365, 410 and 465hp).

The lighter EIO models are generally the first choice where payload is critical, such as on tanker operation. Although Perkins Tx-powered units are rapidly growing in popularity, the E14 remains a favourite among4)ig flOet users at 18 tonnes.

• EVOLUTION

We have focused on one of these; the 261kW (350hp) E14-35 which was introduced alongside the E14-32 in April 1986 as a 4x2 and later appeared in three-axled form. More than 100 of them were twinsteers, most with sleeper cabs. These models were replaced in September 1990 by more powerful E14-36s with the revised E365 Cummins engine.

In line with ERF's dedicated driveline policy, it offers the 12-speed Eaton Twin Splitter as standard, rated to match engine outputs.

Options include a choice of Eaton's semiautomated mechanical transmission (SAMT), based on the popular Twin Splitter or a suitable Eaton Fuller Roadranger constant-mesh box. Rockwell single-reduction axles come with a variety of final drives, and while ERF doesn't offer a rear axle with electronically controlled air suspension, it does offer a standard four-bag system for around £2,250.

Recently ERF has taken to fitting antilock braking, Lucas Simplex automatic slack adjusters and speed limiters as standard on all heavy tractors and drawbar units. It fits 295/80 tubeless tyres and 6.7-tonne front springs to all its 4x2s except for the E8 range,

• DEALER FEEDBACK

From a dealer's viewpoint the ERF E14-35 sells well — when they can get their hands on them. The fact that there was never enough of them made seems to be backed up by the fact that neither Glass's Guide or the CAP Red Book lists a price for the model, instead, the more common E14-32 is included.

According to CAP's Tirn Wilcox, E14-35s rarely appear at auctions so they tend to escape the attention of used truck buyers, but Lombard North Central's motor finance man Bob Wiggins commends them, and the ElOs, for good residual values. All prices have fallen considerably over the past two years, he adds, but he expects things to improve soon.

Alan Blake of Reliance Commercial Vehicles in Brighouse, West Yorks, says it was mainly owner-operators and small fleets who went for 261kW 14-litre models. Because so few were made they tend to be snapped up quickly and command a good price into the bargain; for reference the less powerful E14-32 retails for around £18,000 for a three-year-old example.

Blake agrees that the E14-35 andits more powerful successor have fairly high residual values. One advantage he says "is that plastic cab which doesn't rust. With a new paint job and in a new owner's livery it will sit outside awaiting collection and very often draw more enquiries."

With today's high cost of tyres, a prospective buyer should take particular note of what a used E14-35 is shod with.

Although a 14-litre engine can still have a lot of life left in it after 800,000Iun the figure on the dock is also important. Most new ERFs now have autolube, but it is worth checking when a used E14-35 had it fitted.

Whether it has come from a nationally known operator, a smaller fleet, or an owner-driver, it is always important to look at an artic's history.

"Most have excellent servicing systems and keep very full records, but one of the problems is getting hold of them as there is quite a lot of secrecy involved," says Blake.

This is due mainly to the competitiveness between operators. If one firm has an afterhours arrangement on maintenance or with, say, ATS to look after its tyres, they might well be very cost-effective procedures that he won't want his competitors to know about.

To get the best cover Blake recommends buying secondhand from franchised dealers like his own, which can offer a 12-month extended warranty. Potential buyers might also consider Cummins' extended warranty on engines up to four years old.

• OPERATOR EXPERIENCE

Whatever size operator ends up using ERFs, those that we contacted shared a high regard for its fleet machine reputation.

Clitheroe-based AJA Smith's owner Tony Smith, never one to court publicit, simply calls his ERF E14s a "no-risk combination". His fleet of 22 ERFs comprises 10 E14-35s and a dozen E14-36s; all twin steers used for tipper work. Transport manager Jeff Crowther says: "We buy them new with Eaton's Fuller 14613 box and fit everything that a driver needs to be comfortable. We add tipper hydraulics, auto-lube, reversing and burglar alarms, plus road and engine speed governors."

There is little difference in journey times but fuel consumption has improved enough to save AJA Smith around £300 per week across the fleet. "We've extended the 14-litre's oil service from two to three monthly but we change every filter element at the same time and we expect close to a million kilometres before any major surgery," he says, His only gripe with the G-reg E14 is the ERF stainless steel exhaust system: "It's poor quality and nowhere near as good as the Eminox or Wasey product," he says, and they are also badly routed underneath with flimsy lower mounting brackets so they get knocked off regularly in the quarries. "They should have been routed vertically in the first place," says Crowther.

"Apart from the odd injector, we get total reliability from our E14-35s and 36s for minimal maintenance. You can't ask for better than that," he adds.

As to why owner Tony Smith chose the E14 over the E10: "You just don't put a racehorse to the plough," he says wryly.

While the LIO has been a popular choice with fleets the 14-litre still commands a great deal of respect — not least since problems with gasket leaks hit the 10-litre. In 1988 Cummins changed the L10 cylinder head gasket design and "experienced a rise in instances of water leaks". It went back to the old design in November '88 but the problem took its time to work out. Some operators have also experienced trouble with leaks around the timing cover on the L10. These niggles have all helped enhance the E14's reputation for durability and haven't hurt residuals either.

Owner-driver Steve Degg of SCD Transport in Milton Keynes is running a pair of • lower powered G-reg E14-32s on container work, in preference to the E14-35s. "Mine should be RAFs not ERFs," he says. They're doing up to 2,400km weekly over main roads and motorways and returning 43.540.41it/100km (6.5-7.0mpg)."Apart from a single clutch change, there's been little to complain about so far, although one has begun blowing headlight bulbs," he says, "I've had to replace 10 in one week." Thankfully parts are not as expensive as for some makes and the ERF seems to resist wear and tear better.

"I intended keeping them for 10 years," says Degg, "but with the present state of affairs it will be 20. Rates are disgracefully low and customers quibble about a 10minute delay then make you wait 90 days for payment. It's a national disgrace."

Across the country in Sittingbourne, Kent, EH Nicholls runs a mixed bag of 40 E10, E12 and E14 4x2 and 6x2s and in general has had few problems with them.

Workshop manager Don Macleod believes that Cummins has the best engine and ERF one of the best fleet trucks on the market today. Like AJA Smith the firm works them hard and expects at least 800,000km before it looks at the bottom end of an engine.

Thanks to the Twin Splitter the transmissions have good service life — some of its four-year-old E14-35s still have their original clutches.

Parts are reasonable but Cummins can be very fussy about the quality of returned items like crankshafts, pins or con-rods. It will return them and bill the provider if their condition is too bad.

Macleod criticises ERF's twin steers for heavy tyre wear and linkage problems, which is why the fleet mix is moving back to 4x2s.

"We pay up to £4,000 more initially, yet they cost us an extra 50% on replacement tyres," he says. "There are tax advantages on 3+3 but we lose payload and rub tyres off too often. Over six to eight years we can be many thousands of pounds down."

Macleod also points to problems with kingpin top swivel bearings on the second steer axle. Despite auto-lube, extra flats and grooves appear on the bearing tracks, and the track rod ends wear out much quicker than usual.

"The worst thing ERF ever did," he says, "was to change from a Rockwell steer axle to GKN. We still run several Y-reg ERFs with Gardner 8LXCTs and they are still on their original pins and bearings, so something is not right." He is also critical about the spherical joints on the exhaust systems, which keep breaking.

"We're not over the moon about ERF going back to using fuses instead of trip .Z1ry switches either," he t.1°0adds, "but then, ERF doesn't always listen to small independents like us." Macleod is not too happy with Econocruise either. Of the 20 tractive units fitted with the device, five developed faults all at the same time.

Perhaps Nicholls' biggest regret with its ERFs was choosing to specify the Gardner 6LYT. "We had 11 at one stage," he says. "One did 600,000km but we had to rebuild it nine times, and with shells costing £700 a set and £300 for big ends (compared with £150 and £90 for the E14-32) we were crying ourselves to sleep at night. We are now gradually replacing them with the Cummins 14-Litre, as and when.

"We still have our problems," says Macleod, "but the old E14-32 and 35s are really very reliable and a great fleet tool on our general haulage. They travel well and we have no qualms about sending threeand four-year-old E14s together with our best drivers to France, Germany or Italy."

• SUMMARY

The combination of a Cummins/Eaton/ Rockwell driveline and ERF's plastic cab clearly makes a lot of sense as a hard-working secondhand buy for the small fleet operator.

Although the cab lacks the sophistication of similar models from continental rivals like Scania, the owners we spoke to had very few complaints about the engine and transmission, with the lightly-stressed Cummins 14-litre diesel notable for its ability to cope with high-mileage operations without costing an arm and a leg to maintain.

We uncovered a number of niggling faults, such as excessive tyre wear and bearing problems on the twin-steers, but on the whole the E14 appears to be a reliable machine; the low cost of spare parts is also a point in its favour.

If there is a particular comment on the E14-35, as distinct from the E14-32, it is that examples of the more powerful model are very thin on the ground, so operators who want the extra oomph may have to be patient in their search. With its fleet image, the ERF may never appeal to ownerdrivers, but, as a value-for-money secondhand tractor with plenty of life left in it, a young E14 looks well worth consideration. LI by Bryan Jarvis