A Safe and Ingenious Petrol Gauge

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

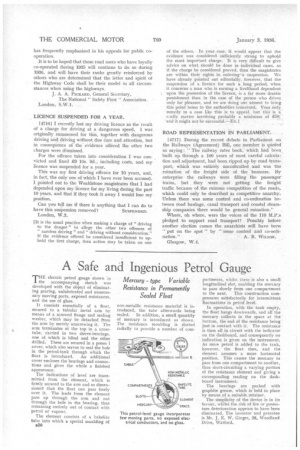

Mercury type Variable Resistance in Permanently Sealed Float

THE electric petrol gauge shown in the accompanying sketch was developed with the object of eliminating gearing, unlubricated and unnecessary moving parts, exposed resistances, and the use of glass.

It consists essentially of a float, secured to a tubular metal arm by means of a screwed flange and sealing washer, which may be detached from the arm by merely unscrewing it. The arm terminates at the top in a crosstube, carried in two sleeve-bearings, one of which is blind and the other drilled. These are secured in a pressc I cover, which also serves to seal the hole in the petrol-tank through which the float is introduced. An additional cover encloses the bearings and connections and gives the whole a finished appearance.

The indications of level are transmitted from the element, which is firmly secured to the arm and so dimensioned that the float can pass freely over it. The leads from the element pass up through the arm and out through the hole in the bearing, thus remaining entirely out of contact with petrol or vapour.

The element consists of a bakeli Le tube into which a special moulding of 8.30

non-metallic resistance material is introduced, the tube afterwards being sealed. In addition, a small quantity of mercury is introduced as shown. The resistance moulding is slotted radially to provide a number of corn partments, whi1t there is also a small longitudinal slot, enabling the mercury to pass slowly from one compartment

to the next. This construction compensates satisfactorily for intermittent fluctuations in petrol level.

In operation, with the tank empty, the float hangs downwards, and all the mercury collects in the space at the bottom, the end of the resistance being just in contact with it. The resistance is then all in circuit with the indicator on the dashboard, and consequently no indication is given on the instrument. As more petrol is added to the tank, however, the float rises, and the element assumes a more horizontal position. This causes the mercury to pass from one compartment to another, thus short-circuiting a varying portion of the resistance element and giving a corresponding reading on the dashboard instrument.

The bearings are packed with graphite grease, which is held in place by means of a suitable retainer. The simplicity of the device is in its favour, whilst the risk of fire or premature deterioration appears to have been eliminated. The inventor and patentee is Mr. J. E. W. Ginger, 28, Woodland Drive, Watford.