South London haulier Robson nearly folded six years ago—a victim

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

of over-expansion and failure to control costs. Now fitter, leaner and wiser, it attributes its renewed success to a strict quality control programme.

Ted Robson comes across as very straight and uncomplicated— probably the same qualities he brings to the job of running a small distribution company in Deptford, south London.

Client loyalty has been vital to the company's turnover of £2m a year with an impressive order book in the food and drink warehousing and distribution sector. But in these tough times, positive qualities need to be backed up with sound judgement and good luck. Despite hiccups, Robson seems to have garnered its share of both.

The firm was launched over 40 years ago by Charlie Robson, father of directors Ted and Mick. Although still chairman, Charlie spends a lot of time on mercy missions to Bosnia so that most of the day-to-day company business falls to his sons. Ted deals with the staff of 26, while Mick is in charge of operations.

For most of the company's life it continued to expand until it had depots nationwide and a large fleet. But six years ago, the bubble burst. The company had grown too big and its bank sent in a troubleshooter to sort out the mess with the warning: "do what he says or else".

It was a painful experience, recalls Ted Robson. to have to lay off long-serving staff just before Christmas. But the lesson sank in. Never again would the company stand by while the business floundered. In future the directors would keep better tabs on profitability and heed the warning signs.

Despite the setback, Robson was wellplaced to recover. It owned the freehold of its strategically-located, three-acre site. And it retained a major contract with brewer Holsten. Brewery work is much sought after because it is lucrative and hassle-freealmost all deliveries include a return load which guarantees a round-trip rate.

The contract is renewed every three years without a hitch, although that does not imply that the relationship is too cosy to stand up to rigorous scrutiny. In fact, Robson insists on an arrangement whereby the client monitors its performance closely, enabling problems to be solved cleanly and swiftly. "We want to deliver 100% service," says Ted Robson.

That sounds wonderful in theory. But what happens if your drivers all fall sick, as many have done this winter, and you can't meet that exacting delivery record? Ted Robson believes it is all down to keeping the client informed. "If there are problems, we tell the client immediately, in the same way we tell the bank if we perceive cash-flow problems."

The company also offers bonded warehouse facilities which meet Customs and Excise's exacting requirements. Record keeping has to be meticulous to ensure that duty is paid on the right consignments at the right time. Robson is also no slouch at taking on the benefits of information technology having operated computerised tracking, journey planning and fuel monitoring for several years.

When Robson elected to go for quality assurance certification (BS5750) in 1991, the directors were confident the transition would be relatively easy since many of the procedures were already in place. Sure enough, they achieved BS5750 status in just four months.

The benefits, according to Ted Robson have been enormous. "We can show the savings we make on everything from tyres to fuel and wages," he says. "Through it, we are eligible to join Michelin's tyre bank, which credits us with casings for our worn tyres which we return to them, We only use Michelin tyres and keep records on where they are used and for how long. If there are problems, we can go back to Michelin."

As for fuel, the system obliges the company to obtain quotes for diesel before ordering, so it can shop around for the best deal. Wages are strictly monitored to prevent any last minute demands for fork-lift truck drivers in the warehouse necessitating the additional presence of a manager, If those needs arise, then someone is held responsible and has to take the blame—it's one of the underlying principles of quality assurance.

No doubt the system sounds a dream to the company accountant but a nightmare to its administrator. But Ted Robson is a committed fan. Bringing in BS5750 has not resulted in more work for the administration team, he insists.

In fact, the workload has been reduced. Most of the burden of keeping tabs has been carried by Mick Robson. Now the company has seen the benefits it brings to clients It is, in turn, demanding a better service from its own subcontractors and suppliers.

The family tries to avoid the pitfall of being too inward-looking by employing an ex-brewery executive as a part-time consultant. He gives valuable independent advice on a range of issues. He helps Robson win new orders by sharpening its presentation skills and giving it confidence in the service it provides, He also advises on health and safety matters including recommending a heated toilet seat!

Depot security includes a closed-circuit television monitoring system and electronic gates. This month its spending on security systems for its 4,645m2 of storage space will reach a total of £60,000 although some of this will be recouped on a reduced wages bill for security personnel.

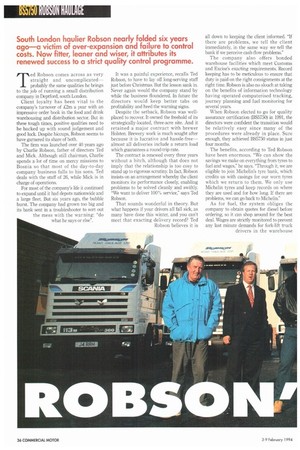

The firm directly employs 10 drivers and its eight-vehicle all-Scania fleet consists of five 38-tonne Centurions, two G.reg 38.tonners and a 17-tonne rigid. Other vehicles arc hired in to meet the seasonal demands of the brewing trade. In addition, it runs a fleet of eight 17-tonners on a single contract with the vehicles manned by owner drivers.

It makes sense to stick to one manufacturer for its own vehicles, reckons Robson: "We buy new and renew every four years via partexchange which helps to keep the bills down and ensures the vehicles are in good working order."

He is so impressed with the Centurion—built by Scania in a limited edition to celebrate its 100th anniversary--that he founded and runs the national owners' club: The Centurion is streamlined so it has lower fuel consumption; it is compact, so bits don't fall off and it never looks tatty. It is good on safety and comfort and never noisy," he avows with the fervour of a true fan.

To safeguard its future, the company is chasing orders from smaller food retailing and manufacturing chains and is determined to avoid some of the excesses it has seen among its rivals. It will not be cutting its throat to win work in the big league. "It is not worth killing yourself," reasons Ted Robson.

11 by Kathy Watson