A Breakaway Device for Trailer Brakes A CONTROL unit for actuating

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

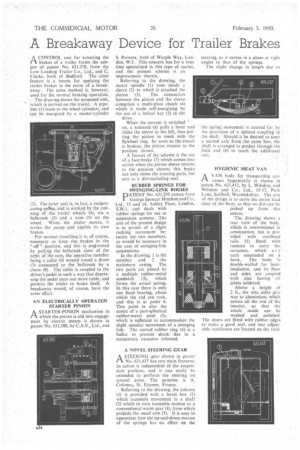

the brakes of a trailer forms the subject of patent No. 631,378, from the Low Loading Trailer Co., Ltd., and C. Clarke. both of Bedford. The chief feature is a means for applying the trailer brakes in the event of a breakaway. The same method is, however, used for the normal braking operation.

The drawing shows the proposed unit, which is carried on the trailer. A pipeline (1) leads to the wheel cylinders, and can be energized by a master-cylinder 12). The latter unit is, in fact, a reciprocating pultip, and is worked by the running of the trailer wheels (4), via a bellcrauk (3) and a cam(5) on the wheel. When the trailer moves,. it works the pump and applies its own brakes.

• For normal travelling it is, of course, 'necessary to keep the brakes in the

off "position, and this is peWormed by pulling the bellcrank clear of the orbit of the cam, the operative member being a cable (6) wound round a drum (7) connected to the bellcrank -by a chain (8). The cable is coupled to the driver's pedal in such a way that depressing the pedal pays out more cable, and permits the trailer to brake itself. A breakaway would, of course, have the same effect.

AN ELECTRICALLY OPERATED STARTER PINION A STARTER-P1NION mechanism in 1-1 which the pinion is slid into engagement by electric means is shown in patent No. 631,580, by C.A.V., Ltd., and S. Parsons, both of Warple Way, London, W.3. This -concern has for a lony time specialized in this type of starter, and the present scheme is an improvement therein..

Referring to the drawing, the motor spindle (1) runs inside a• sleeve (2) to which is attached the pinion (3). The connection between the pinion and the sleeve comprises a• multi-plate clutch (4). which is made self-energizing by the use of a helical key (5) in the

drive.

When the current is switched on, a solenoid (6) pulls a lever and slides the sleeve to the left, thus putting the pinion in mesh with the flywheel ring. So soon as the circuit is broken, thepinion returns to the position shown.

A feature of the scheme is the use of a face-brake (7) which comes into action when the pinion sleeve returns to the position shown; this brake not only slows the rotating parts, but acts as a dirt-excluding seal.

RUBBER SPRINGS FOR • SWINGING-LINK BOGIES

PATENT No. 631,295 comes from I George Spencer Moulton and Co., Ltd., 13 and 14; Ashley Place, London, S.W.I, and deals with rubber springs for use in suspension systems. The aim of the present design is to permit of a slight rocking movement between the two members, as would be necessary in the case of swinging-link suspensions.

In the drawing, 1 is the member and 2 the stationary casing. The two parts are joined by a multiple rubber-metal sandwich (3), which forms the actual spring. In this case there is only one fixed bearing, about which the rod can rock, and this is at point4. This point is also the centre of a part-spherical rubber-metal joint (5), which is sufficient to accommodate the slight annular movement of a swinging link. The curved rubber ring (6) is a buffer to prevent shock due to a momentary excessive rebound.

A NOVEL STEERING GEAR ,k STEERING gear shown in patent 1-1. No. 631,437 has two main features; its action is independent of the suspension position, and it can easily be extended to perform 'the steering on several axles. The patentee is A. Colonna, St. Etienne, France.

Referring to the drawing, the column (I) is provided with a bevel box (2) which transmits movement to a shaft (3) which in turn transmits motion to a conventional worm gear (4), from which projects the usual arm (5). It is easy to appreciate how the up-and-down motion of the springs has no effect on tile steering, as it moves in a plane at right angles to that of the springs.

The slight change in length due to

the spring movement is catered for by the provision of a splined Coupling in ` the shaft. Should it be desired to steer a second -axle from the same box; the shaft is arranged to project through the .back end (6) to reach the additional unit.

HYGIENIC MEAT VAN

AVAN body for transporting carcasses hygienically is shown in patent No 631,413, by L. Wilsdon, and Wilsdon and Co., Ltd., 15-17. Park Lane, Solihull, Warwickshire. The aim of the design is to carry the entire load clear of the floor, so that no dirt can be picked up from this source.

The drawing shows a rear view of the body, which is conventional in construction, but is provided with overhead rails (1) fitted with runners to carry the carcasses, which a r each suspended on a hook. The body is double-walled for heatinsulation, and its floor and sides are covered with zinc having all joints soldered.

Above a height of 2 ft., the zinc sides give way to aluminium, which covers all the rest of the interior, so that the whole inside can be washed and polished. The doors are fitted with rubber edges to make a good seal, and two adjustable ventilators are located on the roof.