An Engine Suspension System fof Cross-country Conditions

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

THAT British manufacturers are I conversant with the requirements oi overseas operators, and appreciate se conditions with which they have to contend and under which the vehicles are run, is manifested by a design emanating from the Guy company. As is well known; this commercial-vehicle maker has for many years concentrated to no mean extent upon the development of cross-country chassis.

The design in point relates to a system Of engine mounting which renders the power unit unaffected by distortion of the frame which otherwise might subject it to undesirable stresses. Details are contained in patent specification No. 515,723, the patentees bei:ig R. Dean-Averns, Rayleigh, York Avenue, Wolverhampton, and Sydney S. Guy, Sauchieleigh, Arbrighton, Shropshire.

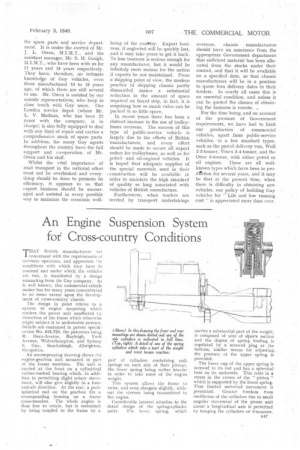

An accompanying drawing shows zhe engine-gearbox unit mounted in part of the frame members. The unit is carried at the front on a cylindrical rubber-bushed bearing which, in addition to permitting slight rotary movement, will also give slightly in a foreand-aft direction. At the rear, a part. spherical end on the gearbox fits a corresponding housing on a frame cross-member. The . whole engine is thus free to rotate, but is restrained by being coupled to the frame by a

pair of cylinders containing coilsprings on each side of their pistons, the lower spring being rather heavier in order to take some of the engine weight.

This system allows the frame to twist, and even.elongate slightly, without the stresses being transmitted to the engine.

Considerable interest attaches to the detail design of the spring-cylinder units. The lower spring, which

carries a substantial part of the weight, is composed of wire of *tare section and the degree of spring loading is regulated by a screwed plug at the bottom, similar means for adjusting. the pressure of the upper spring is provided.

The lower cup Of the upper spring is screwed to its rod and has a spherical boss on its underside. This rests in a recess in the crown of the " piston " which is supported by the lower spring. Thus limited universal movement is permitted. Greater freedom from oscillation of the cylinders due to small angular movement of the power unit about a longitudinal axis is permitted by hanging the cylinders on trunnions.