ANEW

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Road-vehicle

OIL ENGINE

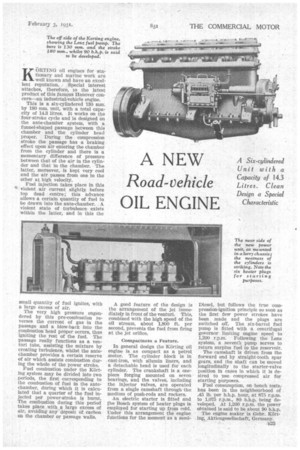

KORTING oil engines for stationary and marine work are well known and have an excel•

lent reputation. Special interest attaches, therefore, to the latest product of this famous Hanover concern—an industrial-vehicle engine.

This is a six-cylindered 130 ram. by 180 mm. unit, with a total capacity of 14.3 litres. It works on the four-stroke cycle and is designed on the ante-chamber system, with a funnel-shaped passage between this chamber and the cylinder head proper. During the compression stroke the passage has a braking effect upon air entering the chamber from the cylinder and there is a momentary difference of pressure between that of the air in the cylinder and that in the chamber. The latter, moreover, is kept very cool and the air passes from one to the other at high velocity.

Fuel injection takes place in this 44 violent air current slightly, before top dead centre; this advance allows a certain quantity of fuel to be drawn into the ante-chamber. A. violent state of turbulence exists within the latter, and in this the

small quantity of fuel ignites, with a large excess of air.

The very high pressure engendered by this pre-combustion reverses the current of gas in the passage and a blow-back into the combustion head proper occurs, thus igniting the rest of the fuel. The passage really functions as a venturi tube, assisting the mixture by creating turbulence, whilst the antechamber provides a certain reserve of air which assists combustion during the whole of the power stroke.

Fuel combustion under the Kiirting system may be divided into two periods, the first corresponding to the combustion of fuel in the antechamber, during which it is calculated that a quarter of the fuel injected per power-stroke is burnt. The combustion during this period takes place with a large excess of air, avoiding any deposit of, carbon on the chamber or passage walls.

A good feature of the design is the arrangement of the jet immediately in front of the venturi. This, combined with the high speed of the oil stream, about 1,800 ft. per second, prevents the fuel from firing at the jet orifice.

Compactness a Feature.

In general design the Kilning oil engine is as compact as a petrol motor. The cylinder block is in cast-iron, with silumin liners, and a detachable head is used for each cylinder. The crankshaft is a onepiece forging mounted on seven bearings, and the valves, including the injector valves, are operated from a single camshaft through the medium of push-rods and rockers.

An electric starter is fitted and the Bosch system of heater plugs is employed for starting up from cold. Under this arrangement the engine functions for the moment as a semi Diesel, but follows the true compression-ignition principle so soon as the first few power strokes have been made and the plugs are switched off. The six-barrel fuel pump is fitted with a centrifugal governor limiting engine speed to 1,200 r.p.m. Following the Lenz system, a seventh pump serves to return surplus fuel to the reservoir.

The camshaft is driven from the forward end by straight-tooth spur gears, and the shaft can be moved longitudinally to the starter-valve position in cases in which it is desired to use compressed air for starting purposes.

Fuel consumption, on bench tests,• has been in the neighbourhood of .45 lb. per b.h.p. hour, at 875 r.p.m. to 1,075 r.p.m., 80 b.h.p. being developed. At 1,200 r.p.m. the power obtained is said to be about 90 b.h.p.

The engine maker is Gehr. Kilning, Aktiengesellschaft, Germany.