BIDDING FOR

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

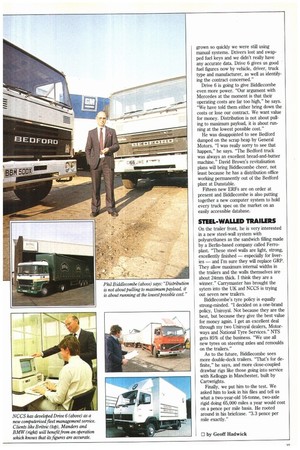

THE BEST Phil Biddlecombe is the man who decides which truck NCCS should buy, when and from whom. He is a powerful man, but how does he make his decisions?

• Every year, Phil Biddlecombe buys more trucks than most operators own in a lifetime. His shopping bill this year, for instance, is 215 million on new vehicles alone, plus 23.9 million for tyres and maintenance. He presides over a fleet of 1,200 lorries and 1,000 trailers and, as the engineering and operations director of National Carriers Contract Services, Biddlecombe is one of the most powerful vehicle specifiers in the British transport industry.

POWERFUL AXE

Getting to this position has not been easy, but Biddlecombe is now able to wield the powerful axe his purchasing ability gives him. "About three years ago," he says, "we talked to all of the trailer manufacturers we used and told them 'gone are the days when operators like NCCS can afford to spend 212,000 on a trailer and keep it on the books until it rots or is sold!"

He was not overwhelmed by the response. Most of the manufacturers laughed and said "Sorry, but you're going to have to buy our trailers." The exception was Carryrnaster which rang up the following morning and told Biddlecombe "We don't like the idea, but looking at the way things are going, we think you are right". Carrymaster got the deal and continues to be a big supplier to NCCS.

"Surprise, surprise," says Biddlecombe. "The other trailer manufacturers have followed suit since then. We now run all of our trailers on operational leases. They give us the flexibility we need. If I buy a trailer it may well last for 10 years. But what happens if the contract for which I purchased the trailers only lasts five years? With operational leasing I just send the trailer back to the manufacturer or leasing company if I don't need it."

Economies of scale and clout are in Biddlecombe's favour when he is negotiating deals like this. He remains, however, a down-to-earth fleet engineer at heart, and he loves to talk trucks.

"I come from a maintenance and engineering background," says Biddlecombe, "and I've always held positions closely involved with the operational side of things." He was a regional director with the old National Carriers set up. He knows the business from the ground up and he gets involved with new contracts. "My department specifies and procures all of the equipment at NCCS."

There is no specific answer, policy or system to aid Biddlecombe and his team in doing this. Each client needs an individual assessment and, he says. "We will always specify the vehicle that best meets the customer's needs". High mileage contracts often get Volvos, Scanias and Mercedes trucks from NCCS, and lower mileage trunking runs often get Leylands. Pressed to praise he will admit "Scania still manages to keep an edge over the rest in reliability and durability," though "40% of our fleet is now Leyland. The people at Leyland, and their trucks, really do do an excellent job for us."

The sort of basic criteria NCCS takes into account when planning a new contract are the prospective client's routeing, operating hours, and distribution systems. Also, the location of the client's warehouses and its history are important, along with the type of traffic normally used and the average GVW needed. Annual mileages are calculated and Biddlecombe then decides whether to specify rigids, artics, demounts, drawbars or whatever.

The bedrock to many of Biddlecombe's policies is accurate costing. "Four years ago we designed our own fixed-life maintenance contract," he says. "We have 250 workshops in the NFC nationwide, and a lot of costs drawn from experience. In fact, it is so good, many dealers will accept our, rather than their own, fixed prices."

The system comes into its own if NCCS takes on a new contract and has to renew a proportion of the fleet it acquires. "We know exactly which vehicles to keep and which to scrap," says Biddlecombe. "We have costings for every mileage category and every weight category from one to five years." If a truck does not meet the NCCS minimum in Biddlecombe's system, it is out. He does not go beyond five years. "I think it is quite unreasonable to expect anyone to guarantee a fixed price maintenance system after a truck is five years old," he says.

Fuel economy is important too, and Biddlecombe is now using Drive 6, a 12 month-old fleet management computer program NCCS has developed. "Until a year ago," he says, "the company had gown so quickly we were still using manual systems. Drivers lost and swapped fuel keys and we didn't really have any accurate data. Drive 6 gives us good fuel figures now by vehicle, driver, truck type and manufacturer, as well as identifying the contract concerned."

Drive 6 is going to give Biddlecombe even more power. "Our argument with Mercedes at the moment is that their operating costs are far too high," he says. "We have told them either bring down the costs or lose our contract. We want value for money. Distribution is not about pulling to maximum payload, it is about running at the lowest possible cost."

He was disappointed to see Bedford dumped on the scrap heap by General Motors. "I was really sorry to see that happen," he says. "The Bedford truck was always an excellent bread-and-butter machine." David Brown's revitalisation plans will bring Biddlecombe cheer, not least because he has a distribution office working permanently out of the Bedford plant at Dunstable.

Fifteen new ERFs are on order at present and Biddlecombe is also putting together a new computer system to hold every truck spec on the market on an easily accessible database.

STEEL-WAILED TRAILERS

On the trailer front, he is very interested in a new steel-wall system with polyurethanes as the sandwich filling made by a Berlin-based company called Ferroplast. "These steel walls are light, strong, excellently finished — especially for liveries — and I'm sure they will replace GRP. They allow maximum internal widths in the trailers and the walls themselves are about 24mm thick. I think they are a winner." Carrymaster has brought the sytem into the UK and NCCS is trying out seven new trailers.

Biddlecombe's tyre policy is equally strong-minded. "I decided on a one-brand policy, Uniroyal. Not because they are the best, but because they give the best value for money again. I get an excellent deal through my two Uniroyal dealers, Motorways and National Tyre Services." NTS gets 85% of the business. "We use all new tyres on steering axles and remoulds on the trailers."

As to the future, Biddlecombe sees more double-deck trailers. "That's for definite," he says, and more close-coupled drawbar rigs like those going into service with Kelloggs in Manchester, built by Cartwrights.

Finally, we put him to-the test. We asked him to look in his files and tell us what a two-year-old 16-tonne, two-axle rigid doing 65,000 miles a year would cost on a pence per mile basis. He rooted around in his briefcase. "3.3 pence per mile exactly."

El by Geoff Hadwick