B IGGER ROOF B IGGER HOOF

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

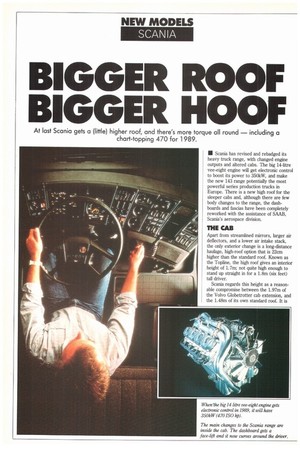

At last Scania gets a (little) higher roof, and there's more torque all round — including a chart-topping 470 for 1989.

• Scania has revised and rebadged its heavy truck range, with changed engine outputs and altered cabs. The big 14-litre vee-eight engine will get electronic control to boost its power to 350AW, and make the new 143 range potentially the most powerful series production trucks in Europe. There is a new high roof for the sleeper cabs and, although there are few body changes to the range, the dashboards and fascias have been completely reworked with the assistance of SAAB, Scania's aerospace division.

THE CAB

Apart from streamlined mirrors, larger air deflectors, and a lower air intake stack, the only exterior change is a long-distance haulage, high-roof option that is 22cm higher than the standard roof. Known as the Topline, the high roof gives an interior height of 1.7m; not quite high enough to stand up straight in for a 1.8m (six feet) tall driver.

Scania regards this height as a reasonable compromise between the 1.97m of the Volvo Globetrotter cab extension, and the 1.48m of its own standard roof. It is possible that the height of the roof marks the maximum pressing that can be achieved for this panel without major reworking of other panels and the production process, and the new roof does provide more storage space for over-thewindscreen items like radios and maps. Also included in the Topline specification is a passenger seat that can be slid all the way to the rear cab wall, and forward to the dashboard: the seat belts have anchor points on the seat backs so that they can be used in any seat position.

The Topline sleeper cab features a four-point air suspension system that keeps the cab level by means of two load valves. There is also a smoke-coloured sun visor.

The seats still have air-suspension, although Scalia's chassis engineering chief Kaj Holmelius feels that it is redundant with the air-suspended cab, because the driver and the dashboard should not be sprung separately, and the cab suspension provides ample comfort.

All models get the new fascia design that curves round the driver and is built in modules so that components can be swapped around in groups for the right-handdrive vehicles, and between models.

The heating and ventilation system has been improved with better switches and more air capacity. The light switch and heater controls now have rotary controls. The instrument panels have a different layout and are illuminated in green light.

Cab interiors have new panels and trimmings, and there is more insulation to reduce the in-cab noise. A single key opens all the door locks, with central locking on the Topline sleeper cab. Electric windows become standard on all models, and the gear lever, while retaining its position, gains a spherical end.

ENGINES

All the engines now comply with ECE R49 emissions standards minus 20%. Two new engines have been added to the range and two have been dropped. All have more torque by virtue of some fuel pump tweaking, and the power, although it appears to be up is in fact unchanged on most of the units — it is only the measurement standard that has changed.

The 14-litre vee-eight engine has new pistons with thicker compression rings and oil cooling ducts with a higher-capacity cooling fan. The torque is up to 1,915Nm at 1,150rpm, and the power is fnow 336kW (450hp) ISO at 1,900rpm.

The 11-litre engines get revised bowlin-piston combustion chambers to try to improve the swirl of the intake mixture. Compression ratios are up, and different piston rings have been fitted.

Although the company's philosophy is to progressively downspeed its engines, one of the effects of meeting the emissions regulations is that the fuel pump settings required push the revs upwards in the case of these two engines.

The engine power in ISO-measured horsepower appears on a badge at the bottom of the front grille, where the veeeight badge used to live.

Scania also gave its dealers a peek at the Electronic Diesel Control (EDC) engine management system that will not be available in the UK until 1989. It can only be fitted to the 14-litre vee-eight engines, but it should make an appearance on the smaller engines in due course.

The EDC system is bought in from Bosch, and is basically a drive-by-wire system interposed between the accelerator pedal and the fuel pump control rack. A black box microprocessor unit takes readings of the air pressure and temperature, the engine revolutions, coolant temperature, oil pressure and a number of other variables, including the throttle depression. It then commands the fuel pump control rack stepper motor or solenoidcontrolled hydraulic activator, to allow an amount of fuel thiough that takes into account all of the limiting variables.

EDC replaces the mechanical centrifugal governor and allows the revs to be extended in the five lower gears. This takes the power up to 350kW (470hp ISO). In the other gears the power remains at 336kW (450hp ISO).

The EDC-equipped engines will not even be built until next August and even then they will only be fitted to Swedish Scanias. There is still a lot of work to do on the installations, and supplies of the unit from Bosch are slow at the moment.

DRIVELINES

To cope with the greater power from the vee-eight engines the heavy-duty GR880 replaces the old-type GR871 box. The new box has larger, stronger teeth, improved spray lubrication and a double action synchromesh on the range change. This uses two sets of synchromesh cones that come into action in two stages to provide more effective braking of the shafts. The gearbox also comes with the options of several different power-take-offs, and a torque convertor for heavy haulage work. The convertor amplifies the engine torque by 1.7, and should provide for easier manoeuvring with heavy loads or snow ploughing. The converter fits between the gearbox and the engine.

The clutch is still used for gear changing in all gears, but drive will not be engaged unless the engine speed is increased above idle.

There is a mechanical lock-up which automatically turns the torque convertor into a solid drive once the input and output speeds are synchronised. The torque convertor will only operate in the low range of the Scania 10-speed gearbox. CAG computer-assisted gearchanging remains optional on all the gearboxes, but is not yet available on the torque convertorequipped gearboxes. An uprated propshaft, the P60 will also be fitted to the heavy haulage models.

SUSPENSION

Steering changes have been made on all models with the inclusion of taper roller bearings at the tops of the kingpins, and lower steering box ratios. These two modifications combine to give the steering more feel, with more direct gearing.

Two-leaf parabolic springs with a third helper spring on the rear replace the multileaf assemblies on all 4x 2 models. The springs are new on all the models except the Urban and 6x214 models.

Anti-roll bars are now standard front and rear on all 4x2 models except rigids, and Scania air suspension is now an option on all twin-steer models. On the 93 models the G and P 4x2 models have relocated air stacks, and turbocharger and gear linkages. This allows the load platform to be extended 22cm further forward giving an extra 1.5m in load volume.

OTHER RESEARCH

Scania is continuing to research into composite springs, says Holmelius, but there are many problems associated with their introduction. Co-operation with G101 ceased recently after the UK-based firm ran into more and more difficulties in fitting composite springs to vehicles above than 3.5 tonnes.

Scalia has now joined forces with its aerospace division and formed a small company with the aim of solving some of the problems. Lateral stiffness, spring wind up, mounting points, and delamination are some of the problems that have to be faced, and Holmelius is pessimistic about an early introduction of composite springs.

Thankfully, the problem of drive axle locking under braking is one he is more optimistic about. He feels the problem has now been solved by reducing the size of the wheel cylinders on the S cam brakes. 0 by Andrew English