Road Test of Leyland Freightline Beaver/Scammell Artic

Page 111

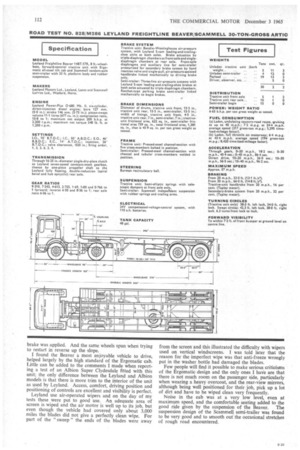

Page 112

Page 113

Page 114

If you've noticed an error in this article please click here to report it so we can fix it.

By A. J. P. Wilding

AMIMechE,MIRTE

114 OST British tractive units available for operation at the higher gross train weights permitted under the

latest Construction and Use Regulations are based on designs offered previously for the maximum 24 tons gross with modifications to braking, suspensions and so on to take care of the extra weight. A radical change in braking is a necessity because secondary systems are required under the latest Regulations and minimum efficiencies for these and service systems have now to be met.

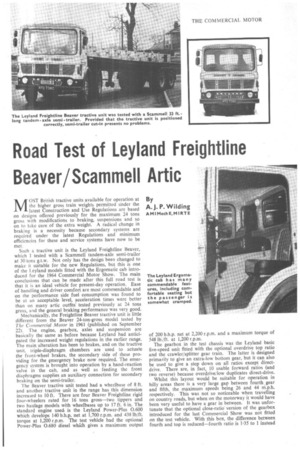

Such a tractive unit is the Leyland Freightline Beaver, which I tested with a Scammell tandem-axle semi-trailer at 30 tons g.t.w. Not only has the design been changed to make it suitable for the new Regulations, but this is one of the Leyland models fitted with the Ergomatic cab introduced for the 1964 Commercial Motor Show. The main conclusions that can be made after this full road test is that it is an ideal vehicle for present-day operation. Ease of handling and driver comfort are most commendable and on the performance side fuel consumption was found to be at an acceptable level, acceleration times were better than on many artic outfits' tested previously at 24 tons gross, and the general braking performance was very good.

Mechanically, the Freightline Beaver tractive unit is little different from the Beaver 24-ton-gross model tested by The Commercial Motor in 1961 (published on September 22). The engine, gearbox, axles and suspension are basically the same as before because Leyland had anticipated the increased weight regulations in the earlier range. The main alteration has been to brakes, and on the tractive unit triple-diaphragm chambers are used to actuate the front-wheel brakes, the secondary side of these providing for the emergency brake now required. The emergency system is brought into operation by a hand-reaction valve in the cab, and as well as feeding the front diaphragms supplies an auxiliary connection for secondary braking on the semi-trailer.

The Beaver tractive unit tested had a wheelbase of 8 ft. and another tractive unit in the range has this dimension increased to 10 ft. There are four Beaver Freightline rigid four-wheelers rated for 16 tons gross—two tippers and two haulage models with wheelbases up to 17 ft. 6 in. The standard engine used, is the Leyland Power-Plus 0.600 which develops 140 b.h.p. net at 1,700 r.p.m. and 438 lb/ft. torque at 1,200 r.p.m. The test vehicle had the optional Power-Plus 0.680 diesel which gives a maximum output of 200 b.h.p. net at 2,200 r.p.m. and a maximum torque of 548 lb./ft. at 1,200 r.p.m.

The gearbox in the test chassis was the Leyland basic five-speed unit fitted with the optional overdrive top ratio and the crawler/splitter gear train. The latter is designed primarily to give an extra-low bottom gear, but it can also be used to give a step down onall ratios except directdrive. There are, in fact, 10 usable forward ratios (and two reverse) because overdrive/low duplicates direct-drive.

Whilst this layout would be suitable for operation in hilly areas there is a very large gap between fourth ,gear and fifth, the maximum speeds being 26 and 44 m.p.h. respectively. This was not so noticeable when travelling on country roads, but when on the motorway it would have been very useful to have a gear in between. It was unfortunate that the optional close-ratio version of the gearbox introduced for the last Commercial Show was not fitted on the test vehicle. With this box, the difference between fourth and top is reduced—fourth ratio is F35 to 1 instead of F689 to 1—and the lower ratios are stepped up to keep the difference between each about the same as on the wideratio unit.

Primary reduction in the rear axle of the Beaver is by spiral-bevel gearing and secondary reduction uses epicyclic gearing in the hubs. The vehicle tested had a 6.06 to 1 overall ratio. This was the middle of three alternatives— the others being 7'74 and 4.82 to 1—and probably the best for normal-type haulage.

The Scammell semi-trailer provided by Leyland for the test could be classed a matched unit as it has identical brakes to those in the driving axle of the Beaver. As on the Beaver braking system, the actuation of the semitrailer brakes is by triple-diaphragm chambers. The semitrailer was not the latest-designed Scammell model as featured at the Glasgow Show. It was to the previous design, with 15 in. pressed-steel, channel-section side members and welded-on cross-members and outriggers. Like the latest model, the semi-trailer is offered with two types of suspension, both based on four independent triangulated arms, interlinked on each side to reduce wheel hop when braking. On one type bellows-design air-springs provide the suspension medium, whilst the alternative version (and the one fitted on the test unit) has stacked rubber springs.

Plated Weights The Beaver Freightline tractive unit is plated for a 5-ton front-axle load and a 10-ton rear-axle load. It will be seen from the accompanying panel that with a 12 in. forward fifth-wheel position these figures were just exceeded with an evenly spread load on the semi-trailer platform. As obviously it is easy to get some slight overload on the driving axle and thus become illegal, I would have preferred to see the vehicle plated for 6 tons front and 10 tons rear—as Beaver rigids are—so that the kingpin could be put farther forward and 5.5 tons and 9.5 tons carried by the two axles. This would give a safety margin in the event of inaccurate loading.

But if this were the case there could be a bad effect in braking, as in the condition as tested, with the driving axle carrying its maximum load, there was locking of the driving wheels on the brake tests. Even so, the figures obtained' were acceptable and the stopping distance of 66 ft. from 30 m.p.h. was almost the same as that obtained on the Beaver/Scammell test at 24 tons gross already referred to. With more effort at the front wheel brakes and it was obvious that these were not doing their fair share of work—excellent figures would, I feel, be obtained.

It is worth pointing out here that there is no difference between the brake sizes on the current Beaver and on the previous 24-ton-gross model. The size of the front-brake actuators has been increased from 12 sq. in. to 20 sq. in., but it was obvious that the proportioning of the brake effort between the four axles of the outfit does not conform to the latest thinking in this country.

The day of the tests started with atrocious weather— there were high winds and heavy rain. Because there was no appearance that it would clear up, brake tests were carried out, from the point of safety, on Leyland's test circuit. Later in the day the rain stopped and the roads dried up just long enough to repeat the service-brake tests. The figures quoted in the panel-33 ft. from 20 m.p.h. and 66 ft. from 30 m.p.h.—were recorded. There was not so much locking of the driving wheels from 20 m.p.h., even on the wet surface, but on every stop from 30 m.p.h. these wheels locked and when in the wet the semi-trailer wheels locked also.

It was interesting to compare the characteristics of the stops using the secondary-brake system and the tractive unit handbrake. It was not possible to check either on a dry road surface, but in the case of the latter the Tapley meter reading of 15 per cent was obtained with the driving wheels locked for about 90 ft., whilst the secondary system check was accompanied by a complete absence of wheel locking. Application of secondary braking to the outer axles of artics as on the Leyland Beaver is now a common practice of British vehicle makers and whilst there can be doubts about the wiseness of this if the front wheels lock there was naturally no trouble with the Leyland. The figure obtained for secondary braking of 32 per cent was made using a Tapley meter. Whilst this meets the legal requirements as they stand now, or as they appear to stand, the way in which the figure was obtained confirmed some

strong doubts that I have about the existing and proposed legislation and "code of practice ". In these, there is no definition of how braking efficiency is to be measured, nor is there any stipulation about delay in the application of a secondary system-0-6 sec. is quoted for the service brakes in the draft code of practice. Without a maximum delay being quoted, Tapley meter readings (or any which show maximum deceleration only) are no use at all.

The 32 per cent obtained with the Leyland meets the law, as I say, but the distance taken to come to a halt was quite considerable (it could not be measured because the brake is applied with a hand reaction valve). This was the result of a delay of well over 2 sec., before full pressure built up in the secondary system, and makes the system of use only if a driver finds a fault in his braking system well before he needs to use his brakes. If the fault is found when the brakes are actually being used to avoid hitting something and then the driver applies his secondary brakes, he might as well not bother.

Regulations vague

I would stress that this is not a criticism of Leyland but of the stupid nature of the regulations and recommendations on braking, which are vague and inconsistent.

For general driving around the brakes felt very good and there was no impression of undue delay in application. Similarly, sufficient power was available from the 0.680 engine and there was no feeling of sluggishness, The gap between fourth gear and direct drive was most noticeable when on M6 and a ratio giving a maximum speed midway between the 26 and 44 m.p.h. in these two gears respectively would have been most appreciated. This would have been provided if the close-ratio box had been fitted and I fully support the Leyland claim that this will give better performance on motorway-type operation. I would go further and say that this box (with the " crawler " option) would be better for all types of work as the 7-89 to 1 bottom ratio that comes with it would be adequate for most conditions.

The use of the crawler/splitter train is mainly of use on hills as it gives only effective split ratios on first to fourth gears; it is not effective on direct-drive and when used in overdrive the overall ratio is approximately 1 to 1. Maximum speeds in the lower gears with the crawler were • found to be 2, 6-5, 12-5 and 21, whilst with the normal gearing they were 5, 8-5, 16 and 26. As already stated, maximum speed in direct-drive was 44 m.p.h. and in overdrive it was 57 m.p.h.

Acceleration tests were carried out without using the crawler ratios and in the through-the-gear runs second gear was used to start. Although the figures obtained for acceleration were not startling, they were quite good and comparable with the results on most 24-ton-gross artics and rigids tested previously. In the direct-drive runs there was a good pull-away from 10 m.p.h. and the figures obtained were also well up to the standard. However, I cannot understand why the 0.600 is the standard engine, as the 0.680 must be the minimum requirement for 30 tons gross.

For the fuel-consumption runs an 11.1-mile route was used and this contained more than eight miles of narrow, winding country roads with a final stretch on the PrestonSouthport dual-carriageway road. Although there are no real hills on this route, a lot of low-gear work was called• for, and this is illustrated by the low average speed of 24-4 m.p.h. returned when 40 m.p.h. was attempted where possible. In the circumstances the consumption was reasonably good and on some of the less-severe routes generally used for road tests I would expect the consumption to be better than 8 m.p.g.

High-speed run

The high-speed, fuel-consumption test consisted of an out-and-return run on M6 measuring 18-9 miles, between the A5239 junction and Bamber Bridge. As this stretch includes fairly long gradients in both the northerly and southerly legs, the figure of 6-4 m.p.g. returned could have been improved if the close-ratio gearbox had been fitted to the test vehicle. When at high speed on the motorway the outfit handled well and showed very good stability.

Gradient performance was checked on Parbold Hill, which is 0-75 mile long and has an average gradient of 1 in 12. Total time taken for the ascent was 5 min. 1 sec., of which 1 min. 18 sec. was spent in second/low gear, the lowest ratio used. Minimum speed on the climb was 6 m.p.h. and no exhaust smoking was noticed on the ascent. It was not possible to take direct engine-coolant temperatures because the system incorporates a header tank, but with the ambient temperature 3°C (37°F) the engine temperature did not rise to more than 79°C (175°F). To check fade resistance, the Beaver outfit was driven down the hill with the brakes applied to restrict the speed to 20 m.p.h. But instead of making the run in neutral it was considered wise because of the road conditions and the gross weight to have direct-drive engaged. This would have taken little of the work off the brakes and when a maximum-pressure stop was made at the bottom from 20 m.p.h., a Tapley meter reading of 49 per cent was obtained. The descent had taken 2 min. 17-4 sec. and the Tapley reading was only 4 per cent less than the best figure obtained from 20 on the cold drum tests which indicated that the outfit should have no problems with fade.

Stop-and-restart tests were carried out successfully when facing up the hill on the steepest (1 in 6-5) section. The handbrake held the outfit satisfactorily when the lever was released—this meant that the brake was held on mechanically and not with air pressure assistance—and a restart in second/low gear was possible. But when facing down the hill, mud on the road resulted in loss of adhesion and the driving wheels locked on one side when the hand brake was applied. And the same wheels spun when trying to restart in reverse up the slope.

I found the Beaver a most enjoyable vehicle to drive, helped largely by the high standard of the Ergomatic cab. Little can be added to the comments I made when reporting a test of an Albion Super Clydesdale fitted with this unit; the only difference between the Leyland and Albion models is that there is more trim to the interior of the unit as used by Leyland. Access, comfort, driving position and positioning of controls are excellent and visibility is perfect.

Leyland use air-operated wipers and on the day of my tests these were put to good use. An adequate area of screen is wiped and the air motor is well up to its job, but even though the vehicle had covered only about 3,000 miles the blades did not give a perfectly clean wipe. For part of the " sweep " the ends of the blades were away from the screen and this illustrated the difficulty with wipers used on vertical windscreens. I was told later that the reason for the imperfect wipe was that anti-freeze wrongly put in the washer bottle had damaged the blades.

Few people will find it possible to make serious criticisms of the Ergomatic design and the only ones I have are that there is not much room on the passenger side, particularly when wearing a heavy overcoat, and the rear-view mirrors, although being well positioned for their job, pick up a lot of dirt and have to be wiped clean very frequently.

Noise in the cab was at a very low level, even at maximum speed, and the comfortable seating added to the good ride given by the suspension of the Beaver. The suspension design of the Scammell semi-trailer was found to be very good and to smooth out the occasional stretches of rough road encountered.