The New Ensign Three-tonner.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

Tyler Engine—Four-speed Box—Double-reduction Geared Axle.

. The War Department is still taking a continuously increasing toll of three-ton chassis. The condition of affairs remains that this size of chassis is actually unobtainable for very early delivery from any of the established British firms. This state of things will only become modified when the Government's demands decrease. It must, in addition, be recalled that it is impossible for every user of commercial vehicles of this class to follow our persistentry reiterated advice to "come down in the scale."

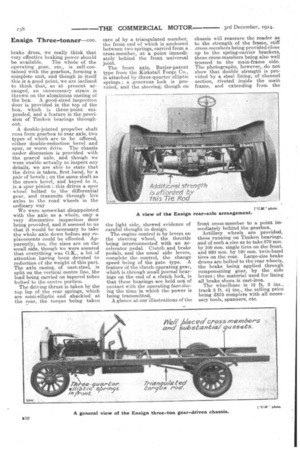

For this and similar reasons we are pleased to be able this week to show further evidence of forthcoming relief ; more is to follow. Our visit to the works of an established maker of touring cars elicited the following particulars of a new chassis for net loads of three tons. The maker in question is British Ensign Motors, Ltd., of Brompton Road, S.W., which has recently taken over convenient premises in Willesden, where chassis are now being constructed of the type referred to, as well as the touring car models for which they are fairly well known. After a perusal of the description below and an examination of the accompanying illustration, our readers will probably agree with us that this is a useful addition to the fleet of "available three-tonners."

The engine, a four-cylinder Tyler, 4i in. by 6 in. bore and stroke, is a well-tried and familiar power unit, with which most of our readers are more or less acquainted.

For the benefit of the remainder, we recall a few particulars. •The engine under review is the 'War Department subsidy pattern, the h.p. by R.A.C. rating being 25, the engine actually developing 35 b.h.p. at 950 r.p.m. The cylinders are east in pairs, with valves all on one side, ample water-jackets being provided round the valves ; the bottom half of the crankcase acts as a sump only, being removable without disturbance of the crankshaft, this last important unit being of nickel steel carefully ground on all bearings. The magneto and water pump are driven by a transverse shaft across the front of the engine. This arrangement renders the magneto contact-breaker very accessible. One of our illustrations gives a good idea of this arrangement. The lubrication of the main and big-end bearings is entirely automatic, the gudgeon pins and cylinders relying on the spray thrown off from the big-ends. The oil pump is at the bottom of the crankcase, and, consequently, is always submerged in oil. A filler is provided

at such a height, that it autonaatoady determines the level in the crankcase. An easily-detachable oil filter, and a pressure indicator on the dash, with a safety release valve inside the crankcase complete the lubricating installation.

The circulating water is taken care of by a centrifugal pump, the piping being of generous dimensions, large enough, in fact, to render thermo-syphoning possible in case of accident to the pump. A large radiator of the built-up type, assisted by a belt-driven fan, succeeds most effectively in cooling this water.

Large and easily-removed inspection doors in crankcase, freed by a turn of a large wing-nut, render the task of inspecting the big-ends a simple, and therefore quite-frequently performed, operation.

, A Cla,udel-Robson carburetter is fitted to the chassis we inspected, but we were given to understand that the Zenith is to be offeved, as an alternative.

From the engine the transmission is via an inverted cone clutch with enclosed spring, the thrust from which is self-contained, two universal joints, of the block and trunnion type, together with a short clutch shaft, intervene between the clutch and gearbox.

Four speeds and reverse, with direct on top, are provided, the box being neat and compact, with short, sturdy shafts, and substantial gears, having teeth of generous size. Immediately behind the box, and arranged so as to overhang by a minimum amount, is the propeller-shaft brake drum, surrounded by shoes of the contracting type, with finger adjustment by means of a wing nut, this wing nut being placed in a fairly accessible position under the driver's seat. From the size of the

brake drum, we really think that very effective braking power should be available. The whole of the operating gear, etc., is self-contamed with the gearbox, forming a complete unit, and though in itself this is a good point, we are inclined to think that, as at present arranged, an unnecessary strain is thrown on the aluminium casting of the box. A good-sized inspection door is provided in the top of the box, which is three-point suspended, and a feature is the provision of Timken bearings throughout.

A double-jointed propeller shaft runs from gearbox to rear axle, two types of which are to be offered, either double-reduction bevel and spur, or worm drive. The chassis under discussion is provided with the geared axle, and though we were unable actually to inspect any details, we are able to state that the drive is taken, first hand, by a pair of bevels ; on the same shaft as the crown bevel, and keyed to it, is a spur pinion ; this drives a spur wheel bolted to the differential gear, and transmits through live axles to the road wheels in the ordinary way We were somewhat disappointed with the axle as a whole, only a very diminutive inspection door being provided, and it seemed to us that it would be necessary to take the whole axle down before any replacements could be effected. Apparently, too, the sizes are on the small side, though we were assured that everything was O.K., a lot of attention having been devoted to reduction of the weight of this part. The axle casing, of cast-steel, is split on the vertical centre line, the load being carried on tapered tubes bolted to the centre portion.

The driving thrust is taken by the top lap of the rear springs, which are semi-elliptic and shackled at the rear, the torque being taken care of by a triangulated member, the front end of which is anchored between two springs, carried from a cross-member, at a point immediately behind the front universal joint.

The front axle, Butler-patent type from the Kirkstall Forge Co., is attached by three-quarter elliptic springs ; a generous lock is provided, and the steering, though on the light side, showed evidence of careful thought in design. The engine control is by levers on the steering wheel, the throttle being interconnected with an accelerator pedal. Clutch and brake pedals, and the usual side levers, complete the control, the change speed being of the gate type. A feature of the clutch-operating gear, which is through small journal bearings on the end of a clutch fork, is that these bearings are held out of contact with the operating face during the time in which the power is being transmitted. A glance at our illustrations of the chassis will reassure the reader as. to the strength of the frame, stiff cross-members being provided close up to the spring-carrier brackets, these cross-members being also well trussed to the main-frame side. The photographs, however, ,do not show that double strength is provided by a steel lining, of channel section, riveted inside the main frame, and extending from the front cross-member to a point immediately behind the gearbox.

Artillery wheels are provided, these running on Timken bearings, and of such a size as to take 870 ram. by 100 ram. single tires on the front, and 920 mm. by 120 ram. twin-band tires on the rear. Large-size brake drums are bolted to the rear wheels, the brake being applied through compensating gear, by theside levers ; the material used for lining all brake shoes is cast-iron.

The wheelbase is 12 ft. 3 ins., track 5 ft. 44 ins., the selling price being £675 complete with all necessary tools, spanners, etc.