The Sheppee Steam Lorry.

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of a New Vehicle which has many Interesting Points.

On the occasion of a recent visit to he old City of York, a representative

the Editorial staff of " COMNIERIAL MOTOR " took the opportunity to )ok in at the Sheppee Motor Company's ,orks in Thomas Street. Mr. F. H. ;heppee, the principal of this energetic ancern, who has devoted a not inonsiderable portion of his time and ubstance to the manufacture of motor chides of this class, is an enthusiastic dyocate of steam for the propelling of 3ad vehicles, and especially of such ma!tines as are designed in accordance pith the principles which were laid own hr the late M. Leon Serpollet. [is latest production is a two-ton hassis, and this is equally suitable for oods or passenger transport. One tachine of its type which the company ; now running has, in fact, been alterately employed as a lorry or a char

-banes. There are many.' interesting oints in the design of this chassis and, ith the assistance of the accompanying lustrations, we hope to make these .ear to our readers.

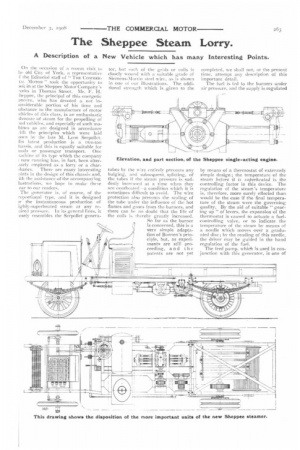

The generator is, of course, of the roportional type, and it is designed )r the instantaneous production of ighlv-superheated steam at any reaired pressure. In its general lines, it oselv resembles the Serpollet genera

tor, but each of the grids or coils is closely wound with a suitable grade of Siemens-Martin steel wire, as is shown in one of our illustrations. The additional strength which is .given to the

tubes by the wire entirely prevents any bulging, and subsequent, splitting, of the tubes if the steam pressure is suddenly increased at a time when they are overheated —a condition which it is sometimes difficult to avoid. The wire protection also prevents the scaling of the tube under the influence of the hot flames and gases from the burners, and there can be no doubt that the life of the coils is thereby greatly increased.

So far as the burner is concerned, this is a 4 very simple adapta tion of Bunsen's principle, but, as experiments are still proceeding, and the patents are not yet completed, we shall not at the present time, attempt any description of this important detail. The fuel is fed to the burners under air pressure, and the supply is regulated

by means of a thermostat of extremely simple design; the temperature of the steam before it is superheated is the controlling factor in this device. The regulation of the steam's temperature is, therefore, more surely effected than would be the case if the final temperature of the steam were the governing quality. By the aid of suitable "gearing up" of levers, the expansion of the thermostat is caused to actuate a fuelcontrolling valve, or to indicate the temperature of the steam by means of a needle which moves over a graduated disc; by the reading of this needle, the driver may be guided in the hand regulation of the fuel.

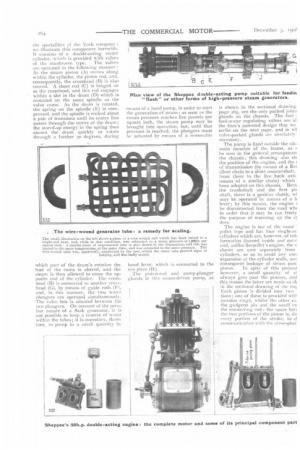

The feed pump, which is used in conjunction with this generator, is one of

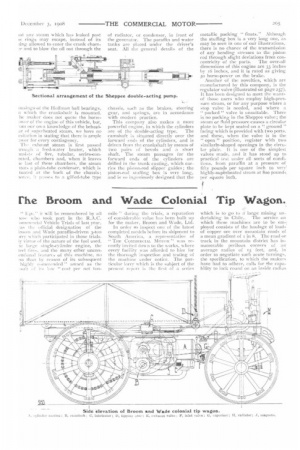

the specialities of the York company : we illustrate this component herewith. It consists of a double-acting steam cylinder, which is provided with valves of the mushroom type. The valves are operated in the following manner : As the steam piston (A) moves along within the cylinder, the piston rod, and, consequently, the crosshead (B) is also moved. A short rod (C) is hinged on to the crosshead, and this rod engages within a slot in the drum (D) which is mounted on the same spindle as the valve cams. As the drum is rotated, the spring on the spindle (E) is compressed, and the spindle is rocked about a pair of trunnions until its centre line passes through the centre of the drum; the stored-up energy in the spring then causes the drum quickly to rotate through a further 30 degrees, during

which part of the drum's rotation the lead of the cams is altered, and the steam is then allowed to enter the opposite end of the cylinder. The crosshead (B) is connected to another crosshead (G), by means of guide rods (F), and, in this manner, the two water plungers are operated simultaneously. The valve box is situated between the two plungers. On account of the peculiar nature of a flash generator, it is not possible to keep a reserve of water within the tubes; it is necessary, therefore, to pump in a small quantity by

means of a hand pump, in order to start the generation of steam; as soon as the steam pressure reaches five pounds per square inch, the steam pump may be brought into operation, but, until that pressure is reached, the plungers must be actuated by means of a removable hand lever, which is connected to the eye piece (H). The piston-rod and pump-plunger glands in this steam-driven pump, as is shown in the sectional drawing page 265, are the only packed joint, glands on the chassis. The fuel feed-water regulating valves are al the firm's patented design that we scribe on the next page, and in wl valve-packed glands are absolutely necessary.

The pump is fixed outside the oilmain member of the frame, as r he seen in the general arrangemen the chassis; this drawing also sh, the position of the engine, and the t of transmission (by means of a Re: silent chain to a short countershaft, from there to the live back axle means of a similar chain) which been adopted on this chassis. Berk% the crankshaft and the first pit shaft, there is a positive clutch, wl may be operated by means of a h lever; by this means, the engine be disconnected from the road wilt in order that it may be run freely the purpose of warming up the cl ders.

The engine is one of the usual pallet type and has four single-ac cylinders which are, however, of tub formation (turned inside and outs and, unlike Serpollet's engine, the v chests are cast separately from cylinders, so as to avoid any une, expansion of the cylinder walls, ane consequent leakage of steam past piston. In spite of this precaui however, a small quantity of st always gets past the pistons, and this reason the latter are made as sh in the sectional drawing of the em. Each piston is divided into two Lions; one of these is provided will pansion rings, whilst the other Ca the gudgeon pin and the small en the connecting rod : the space bet\ the two portions of the piston is, du every portion of the stroke, in d communication with the atmospher

at any steam which has leaked past le rings may escape, instead of its ting allowed to enter the crank cham?r and to blow the oil out through the

ausings of the Hoffman ball bearings, wh'ich the crankshaft is mounted. he maker does not quote the horseAver of the engine of this vehicle, but, out our own knowledge of the behawiLHof superheated steam, we have no L!silation in stating that there is ample DWer for every contingency.

exhaust steam is first passed trough i feed-water heater, which msists of five, tubular, series-conected, chambers and, when it leaves le last of these chambers, the steam ners a plain-tube condenser, which is tualed at the hack of the chassis;

tent.e. passes to a gilled-tube type

of radiator, or condenser, in front of the generator. The paraffin and water tanks are placed under the driver's seat. All the general details of the chassis, such as the brakes, steering gear, and springs, are in accordance with modern practice.

This company also makes a more powerful engine, in which the cylinders

are of the double-acting type. The camshaft is situated directly over the forward ends of the cylinders, and is driven from the crankshaft by means of IWO pairs of bevels and a short shaft. The steam passages for the forward ends of the cylinders are drilled in the trunk casting, which carries the piston-rod slipper guides; the piston-rod stuffingbox is very long, and is so ingeniously designed that the

metallic packing " floats." Although the stuffing box is a very long one, as may be seen in one of our illustrations, there is no chance of the transmission of any bending stresses to the piston rod through slight deviations from concentricity of the parts. The over-all dimensions of this engine are 33 inches by 16 inches, and it is rated as giving 50 horse-power on the brake.

Another of the novelties, which are manufactured by this company, is the regulator valve (illustrated on page 257). It has been designed to meet the wants of those users who employ high-pressure steam, or for any purpose where a stop valve is needed, and where a " packed " valve is unsuitable. There is no packing in the Sheppee valve; the steam or fluid pressure causes a circular plate to be kept seated on a'! ground " facing which is provided with two ports, and these, when the valve is in the " open " position, register with two similarly-shaped openings in the circular plate. It is one of the simplest valves made, and it has stood up to practical test under all sorts of conditions, from paraffin at a pressure of fifty pounds per square inch to very! highly-supbrheated steam at Soo pounds, per square inch.