Assessing the latest

Page 39

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

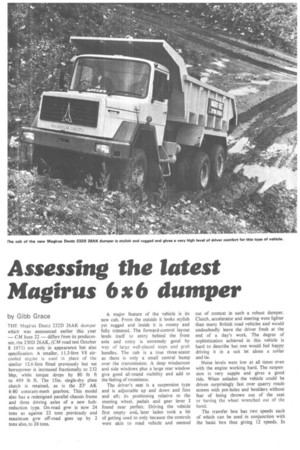

Magirus 6x6 dumper by Gibb Grace THE Magirus Deutz 232D 26AK dumper which_ was announced earlier this year — CM June 22 — differs from its predecessor, the 230D 26AK, (CM road test October 8 1971) not only in appearance but also specification. A smaller, 11.3-litre V8 aircooled engine is used in place of the similar 12.6-litre fitted previously but net horsepower is increased fractionally to 232 bhp, while torque drops by 80 lb ft to 499 lb ft. The 15in. single-dry plate clutch is retained, as is the ZF AK 6-80 constant-mesh gearbox. This model also has a redesigned parallel chassis frame and three driving axles of a new hubreduction type. On-road gvw is now 24 tons as against 22 tons previously and maximum gvvv off-road goes up by 2 tons also, to 26 tons. A major feature of the vehicle is its new cab. From the outside it looks stylish yet rugged and inside it is roomy and fully trimmed. The forward-control layout lends itself to entry behind the front axle and entry is extremely good by way of lare well-placed steps and grab handles. The cab is a true three-seater as there is only a small central hump over the transmission. A deep windscreen and side windows plus a large rear window give good all-round visibility and add to the feeling of roominess.

The driver's seat is a suspension type and is adjustable up and down and fore and aft; its positioning relative to the steering wheel, pedals and gear lever I found near perfect. Driving the vehicle first empty and, later laden took a bit of getting used to only because the controls were akin to road vehicle and seemed

Out of context in such a robust dumper. Clutch, accelerator and steering were lighter than many British road vehicles and would undoubtedly leave the driver fresh at the end of a day's work. The degree of sophistication achieved in this vehicle is hard to describe but one would feel happy driving it in a suit let alone a collar and tie.

Noise levels were low at all times even with the engine working hard. The suspension is very supple and gives a good ride. When unladen the vehicle could be driven surprisingly fast over quarry roads strewn with pot-holes and boulders without fear of being thrown out of the seat or having the wheel wrenched out of the hand.

The transfer box has two speeds each of which can be used in conjunction with the basic box thus giving 12 speeds. In

practice the transfer box is not used like a normal splitter but either the high or low range chosen and then only the normal six-speed box used. The low range giving speeds from 3 to 28 mph is ideal for heavy loads and steep gradients off-road and the high range giving speeds from 5 to 43 mph ideal for 24-ton-gvw on the road.

Climbing ability Climbing ability is tremendous — the vehicle will climb a 1 in 2 gradient at 26 tons gvw in bottom gear in the low range. In the high range on-road at 24-ton-gvw it will climb a I in 10 gradient in third gear. During our test in a quarry the vehicle started away laden to 25 tons gvw on a 1 in 5 hill without any fuss.

The vehicle is permanently in six-wheel drive and the drive line differential lock which operates on the transfer box and bogie simultaneously can be used in high or low range. No cross-axle differential is fitted to the front axle but cross-axle differentials are fitted to the bogie so that five of the six wheels will drive in the worst conditions. The cross-axle differential locks work independently of the drive-line locks and proved to be adequate for most conditions.

Traction

The traction available from the bogie was such that we never really needed the extra bite of the front axle and the few climbs in loose ground that we could not make with just the bogie axles locked could not be made up with drive line locked up either. Very sticky conditions such as deep mud, however, would probably show the benefit of the drive-line lock.

On the road, despite its powerful engine the Magirus, seemed big and cumber. some compared to the more conventional British tipper. But the brakes were light and progressive and the steering accurate.

Owing to the hilly nature of the Derbyshire countryside, level-road acceleration tests proved impossible but the brakes gave 70 per cent on a Tapley meter with all bogie wheels locked. Fuel consumption was checked over a typical working run. The vehicle ran laden from the loading point to the tip and unladen for the return run. The total distance of 8.8 miles took 33 minutes (16 mph). and one-third of the distance was within the quarry. Under these conditions the vehicle returned 3.3 mpg but this figure makes no allowance for engine running time. During the run the engine ran for a further 11 minutes while waiting to be loaded, weighed and during tipping, making the true consumption a little better.

To sum up, the Magirus dumper is a very rugged yet sophisticated vehicle; it is easy and Untiring to drive and makes light work of tough quarry conditions. It is a heavy machine with a kerb weight of 11.3 tons (including body) and expensive — in the region of £13,500 and therefore probably of interest only to those operators intensively engaged in quarry work.

It would be too heavy and too thirsty to compete with a conventional 24-ton tipper if much road work was involved. The driving front axle did not seem, in my short test at least, to give any great extra benefit and I would have thought that the extra traction it gave was not worth the added complexity and cost of the transfer box propshaft and driven axle.