Economy Still Firs in Latest Trojan

Page 70

Page 71

Page 72

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

steering was unaffected.

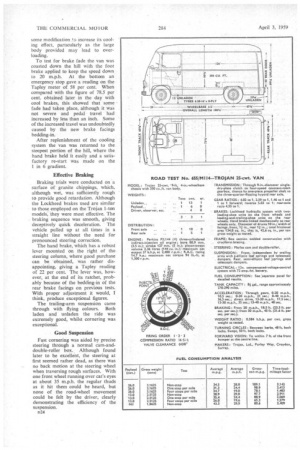

THE Trojan reputation for building vehicles which are noted for fuel economy is enhanced by their latest product, a 25-cwt. forwardcontrol van. On test it carried rather more than its full payload at an average speed of over 28 m.p.h. over a difficult route using fuel at the rate of only 34.5 m.p.g.

The new vehicle is the first fullforward-control chassis to be manufactured by the company. Previous forward-control chassis produced for specialist bodybuilders have been basically forward-control conversions of existing normal-control models.

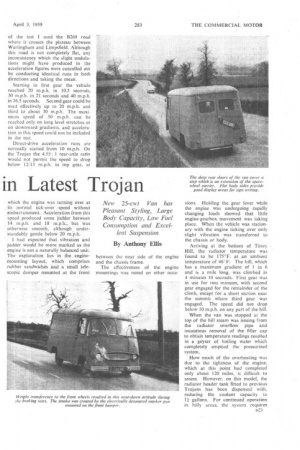

In appearance the new van compares most favourably with its predecessors which might be described kindly as having rather outdated styling. Its attractions, however, do not end there. In addition to the extra 5-cwt. payload capacity provided, the large body gives up to 350 cu. ft, of useful space.

The van has a wheelbase of 9 ft_ 4 in. and follows normal Trojan practice in having a chassis frame made up of box-section members with cruciform bracing to provide a very rigid structure. The test vehicle complied with the standard specification, having a Perkins P3/144 (V) threecylindered indirect-injection oil engine and a four-speed constant-mesh gearbox.

Other models based on the chassis are a personnel carrier and a rural bus which will be available shortly. D22 The Perkins Four 99 1.6-litre oil engine, which was to be used for bus applications of this chassis, is no longer a production option.

The new chassis have the novel Trojan independent front suspension layout originally introduced for the Senior normal-control model. This design incorporates trailing arms to carry the stub-axles, with quarterelliptic leaf springs assisted by telescopic dampers and rubber snubbers.

On arriving at the Trojan works I found that a misunderstanding had occurred over the allocation of a test vehicle. As a result, the vehicle which was provided had come straight from the production line without inspection.

This omission was to make itself felt on one or two occasions during the test, notably when the windscreenwiper drive became deranged— incidentally demonstrating that the front cover panel • was incorrectly fitted—and when the engine, which had covered practically no mileage and was very tight, boiled away most of its coolant during the It is remarkable that good fuel consumption and general performance figures were obtained with the vehicle in an unfinished condition. They would probably have been even better had the vehicle been properly run-in.

The test load was made up of sandbags and 56-1b. weights, and the vehicle was driven to the weighbridge. It was found that 26 cwt. had been put aboard, which, with myself and Mr. S. under good conditions, but in the circumstances they were exceptional.

I was reminded during these runs of the extraordinary ability of the P3/144 engine to continue to pull in a high gear once the engine speed has come down to a point which coincides with the top of the torque curve.

Slow-speed pulling is accompanied by adequate acceleration. For this part which the engine was turning over at its normal tick-over speed without embarrassment. Acceleration from this speed produced some judder between 14 m.p.h. and 18 m.p.h., but was otherwise smooth, although understandably gentle below 20 m.p.h.

I had expected that vibration and judder would be more marked as the engine is not a naturally balanced unit. The explanation lies in the . enginemounting layout, .which comprises rubber sandwiches and a small telescopic damper mounted at the front between the near side of the engine and the chassis frame.

The effectiveness of the engine mountings was noted on other occa

sions. Holding the gear lever while the engine was undergoing rapidly changing loads showed that little engine-gearbox movement was taking place. When the vehicle was station. ary with the engine ticking over only slight vibration was transferred to the chassis or body.

Arriving at the bottom of Titsey Hill, the radiator temperature was found to be 175°F. at an •ambient temperature of 46F. The hill, which has a maximum gradient of I in 6 and is a mile long, was climbed in 4 minutes 10 seconds. First gear was in use for Iwo minutes, with second gear engaged for the remainder of the climb, except for a short section near the summit where third gear was engaged. The speed did not drop below 10 m.p.h. on any part of the hill.

When the van was stopped at the top of the hill steam was issuing from the radiator overflow pipe and incautious removal of the filler cap to obtain temperature readings resulted in a geyser of boiling water which completely emptied the pressurized system.

How much of the overheating was due to the tightness of the engine. which at this point had completed only about 120 miles, is difficult to assess. However, on this model, the radiator header tank fitted to previous Trojans has been dispensed with. reducing the coolant capacity to I+ gallons. For continued operation in hilly areas, the system requires some modification tc, increase its cooling effect, particularly as the large body provided may lead to overloading.

To test for brake fade the van was coasted down the hill with the foot brake applied to keep the speed down to 20 m.p.h. At the bottom an emergency stop gave a reading on the Tapley meter of 58 per cent. When compared with the figure of 78.5 per cent, obtained later in the day with cool brakes, this showed that some fade had taken place, although it was not severe and pedal travel had increased by less than an inch. Some of the increased travel was undoubtedly caused by the new brake facings bedding-in.

After replenishment of the cooling system the van was returned to the steepest portion of the hill, where the hand brake held it easily and a satisfactory re-start was made on the 1 in 6 gradient.

Effective Braking

Braking trials were conducted on a surface of granite chippings, which, although wet, was sufficiently rough to provide good retardation. Although the Lockheed brakes used are similar to those employed on the Trojan 1-ton models, they were most effective. Th.e braking sequence was smooth, giving deceptively quick deceleration. The vehicle pulled up at all times in a straight line without the need for pronounced steering correction.

The hand brake, which has a robust lever mounted on the right of the steering column, where good purchase can be 'obtained, was rather disappointing, giving a Tapley reading of 22 per cent. The lever was, however, at the end of its ratchet, probably because of the bedding-in of the rear brake facings on previous tests. With proper adjustment it would, I think, produce exceptional figures.

The trailing-arm suspension came through with flying colours. Both laden and unladen the ride was extremely good, whilst cornering was exceptional.

Good Suspension

Fast cornering was aided by precise steering through a normal cam-anddouble-roller box. Although found later to be excellent, the steering at first seemed rather dead, as there was no back motion at the steering wheel when traversing rough surfaces. With one front wheel running over cat's eyes at about 35 m.p.h the regular thuds as it hit them could be heard, but none of the road-wheel movement

could be felt by the driver, clearly demonstrating the efficiency of the suspension.

n24

To test it to the 'full I found a deeply pot-holed and rutted track. Driven aliang this at about 25 m.p.h. the van required no more effort to control it than was needed on normal road surfaces.

• .Steering was heavy at low speeds, partly because of the use of a steering wheel of only 161-in. diameter. There • is plenty of room for a larger wheel,

• as the present one is placed rather far from the drivpr. and the Windscreen.

• Unless the ,adjustable seat is moved right forward the.Position of the wheel makes a straight-arm attitude essential. With the seat in this position, however, the delightful straight' gear lever is uncomfortably far from the driver's left hand. Thus the greater purchase provided by a larger wheel would be accompanied by an improved driving position.

Easy Access Access to the driver's seat is good. The deep door, covers a step, well the bottom of which is only 15 in. from the ground when the vehicle is unladen. 'No bulkhead waS fitted behind the driver's seat on the ,test

vehicle, giving' the driver direct access to the load.

Engine noise, which could be severe with the unit situated high up beside the driver, is not excessive—the result of the use of plastics engine covers. This material is employed also for the internal front bulkhead and the instrument cowling. Plastics is used also for the cab roof and for the external front panelling.

The test. vehicle was comprehensively equipped with twin windscreen wipers and flashing indicators. The instrument layout is neat, but no map pockets or containers are incorporated in the dashboard. There is, however, a tool box under the driver's seat.

1 did not have time for the maintenance tests which are usually conducted by The Commercial' Motor. A cursory inspection, however, showed that these should present littIe difficulty. The high engine position, combined with removable panels on each side of the.cowling, each secured by three bolts and two Stews, allows the sides of the Unit to be fully exposed. A flap in the front panel can be let down after releasing two, budget lacks to give access to the radiator filler cap and the two fuse boxes. After this, loosening of tvvo nuts and the removal of two self-tapping screws allow the complete front panel to-be detached There is then clear atcess to, the front of the engine for work on the timing case, radiator or dynamo.

Engine Changes Simplified Simple engine changes are catered for by a special item of equipment supplied by Trojan. This is a small L-shaped gantry which 'fits on to the chassis frame behind the gearbox. The longer, side of the L then protrudes from the front of the vehicle, where it is supported on a tripod. A carriage provided with a sling for attachment to the lifting points of the engine runs along the gantry and in this way the engine can be run out of the vehicle.

The basic price of the van with the three-cylindered engine -and fourspeed gearbox is £935, plus £131 18s. 6d. purchase tax.