THE LATEST 2-TONNER FROM BRISTOL.

Page 9

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

The First Description of a Novel Forward Cab Type Chassis, the Tests of Which Show Remarkable Economy in Fuel and Oil.

CONSIDERABLY over a year ago we learnt that the Bristol Tramways and Carriage Co., Ltd., were contemplating the manufacture of a two-ton .chassis suitable for passenger work or goods carrying, and we have awaited with great interest the production of this machine. The company have taken their time over the matter, as reliability and economical maintenance are consifiered to be essentials, and they did not wish to make the mistake of placing on the market a, vehicle in which these features had not been thoroughly proved.

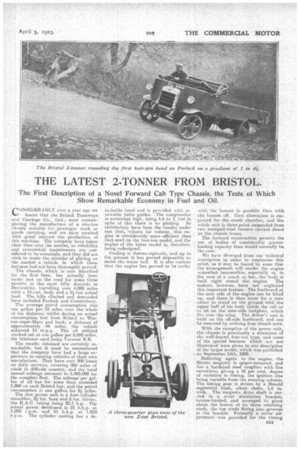

The chassis, which is now 'described for the first time, has actually -been under test on the road for some three months in the most hilly districts in Devonshire, traVelling over 4,000 miles with a 15-cwt. body and a 21-ton actual load. The hills climbed and descended have included Porlock and Countisbury. The average petrol consumption was one gallon per 12 miles over the whole of the distance, whilst during an actual consumption test from Bristol to Weston-super-Mare and hack, a distance of approximately 44 miles, the vehicle achieved 15 m.p.g. The oil utilized worked out at one gallon per 2,000 miles, the lubricant used being Vacuum B.B.

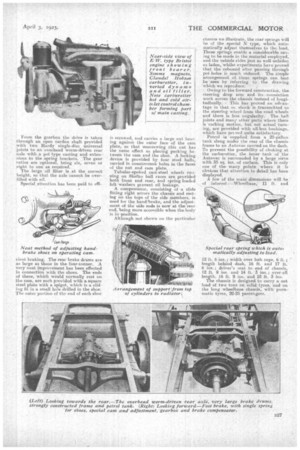

The results obtained are certainly remarkable, but it must be remembered that the company have had a large experience in running vehicles of their own manufacture. They have over 200 buses on daily services, covering 800 miles of roads in difficult country, and the total annual mileage amounts to 5,000,000 for the complete feet. The mileage per gallon of oil has for some time exceeded 1,000 on each Bristol bus, and the petrol consumption is one *anon for 8i miles. The new power unit is a four-cylinder monobloc, 3-1 ins, bore and fi ins, stroke, the R.A.C. rating being 22.5 h.p. Ti actual power developed is 25 .b.h.p. at 1.000 r.p.m. and 45 b.h.p. at 1,850 r.p.m. The cylinder casting has a de

tachable head and is provided with renewable valve guides. The compression is somewhat high, being 4.6 to 1, but in spite of this there is no pinking. So satisfactory have been the results under test that, volume for volume, this engine is considerably more efficient than that used on the four-ton model, and the engine of the latter model is, theiefore, being redesigned: Cooling is thermo-siphonie, and up to the present it has proved impossible to make the water boil. It is also curious that the eugine has proved to be cooler with the bonnet in position than with the bonnet off. Cast aluminium is employed for the crank chamber, and the whole unit is three-point suspended from two stamped-steel bearers carried direct on the chassis frame.

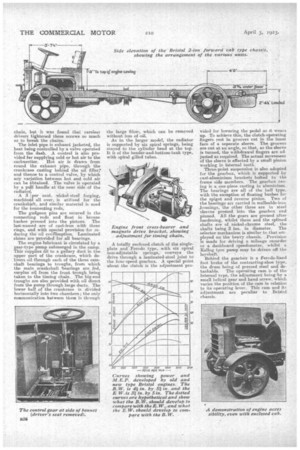

The forward construction permits the use of bodies of considerably greater loading capacity than would normally be Use case.

We have diverged from our tethnical description in order to emphasize this point, as it may be feared by some that the arrangement will render the engine somewhat inaccessible, especially es, in the case of a coach or bus, the body is built right round the engine. The makers, however, have not neglected this important feature. The footboard at the near side of the engine can be lifted up, and there is then room for a man either to stand on the ground with the upper half of his body inside the cab or to sit on the near-side footplate, which fits over the wing. The driver's seat is built on the off-side footboard; and can be removed by undoing four thumb nuts.

With the exception of the power unit, the chassis is practically a miniature of the well-known four-ton type, and some of the special features which are not illustrated were given in our description of the larger model, which was published on September 14th, 1920.

Referring again to the engine, the Simms magneto is spigot-mounted, and has a hardened steel coupling with fine serrations, giaing a 10 per cent, degree of variation in timing, the ignition also being variable from the steering column. The timing gear is driven by a Renold segmental bush, silent chain, 1..6 in. wide. The magneto drive shaft is carried in a stout aluminium bracket, bronze-bushed, and arranged to pivot about the lowest of its three retaining studs, the top studs fitting. into grooves in the bracket-. Formerly a screw adjustment. was provided for the timing

chain, but it was found that careless drivers tightened these screws so much as to break the chains.

The inlet pipe is exhaust jacketed, the heat being controlled by a valve operated from the dash. A control is also provided far supplying cold or hot air to the carburetter. Hot air is drawn from round the exhaust pipe, through the crankcase casting behind the oil filler; and thence to a control valve, by which any var'ation between hot and cold air can be btained. The valve is operated by a p I handle at the near side of the radiate

A 3 per cent. nickel-steel forging, machin d all over, is utilized for the cranksh ft, and similar material is used for the onnecting rods; The gudgeon pins are secured in the connecting rods and float in bronze bushes pressed into the pistons. The last-named are of cast-iron with three rings, and with special provision for reducing the oil conriimption. Laminated shims are provided for all bearings.

The engine lubricant is circulated by a gear-type pump submerged in the sump. This supplies oil to a gallery duct in the upper part of the crankcase, which delivers oil through each of the three camshaft bearings to troughs, from which the main crankshaft 'bearings are fed, surplus oil from the front trough being taken to the timing chain. The big-end troughs are also provided with oil direct from the pump through large ducts. The lower half of the crankcase is divided horizontally into two chambers; the only communication between them is through

the large filter, which can be removed without loss .of ,oit.

As in the larger model, the radiator is supported by six spiral springs, being stayed to the cylinder head at the top. It is of the header-and-bottom-tank type, with spiral gilled tubes.

A totally enclosed clutch of the singleplate and Ferodo type, with six spiral non-adjustable springs, conveys the drive through a laminated-steel joint to the four-speed gearbox. A special point about the clutch is the adjustment pie vitlecl for lowering the pedal as it wears up. To achieve this, the clutch-operating fingers rest in grooves cut in the inner face of a separate sleeve. The grooves are cut at an angle, so that, as the sleeve is turned, the withdrawal fingers are adjusted as required. The actual movement of the sleeve is effected by a small pinion working in internal teeth.

Three-point suspension is also adopted for the gearbox, which is supported by east-aluminium brackets bolted to the frame side members. The gearbox casing is a one-piece casting in aluminium. The bearings are all of the ball type, with the exception of floating bushes for the spigot and reverse pinion. Two of the bearings are carried in malleable-iron _housings, the other three are in steel sleeves pressed into the gearbox and pinned. All the gears are ground after hardening, whilst these and the .splined shafts are of. nickel-chrome steel, the shafts being 2 ins, in diameter. The selector mechanism is similar to that employed on the heavy, chassis. . Provision is made for driving a mileage recorder or a dashboard speedometer, whilst a Kellog tyre pump may be driven off the layshaft.

Behind the gearbox is a Ferodo-lined foot brake of the contracting-shoe type. the drum being of pressed steel and detachable. The operating cam is of the internal type, the adjustment being by a small helical gear and hand screw, which varies the position of the cam in relation to its operating lever. This cam and its adjustment are peculiar to Bristol chassis. From the gearbox the drive is taken through an open cardan shaft provided with two Hardy single-disc universal joints to an overhead worm-driven rear axle with a pot type casting and extensions to the spring brackets. The gear ratios are optional, being six, seven or eight to one as required. The large oil filter is at the correct height, so that the axle cannot be overfilled with oil.

Special attention has been paid to effi.

cient braking. The rear brake drums are as large as those in the four-tonner. A very neat improvement has been effected in connection with the shoes. The ends of these, which would normally rest on the cam, are each imovided with a square steel plate with a spigot, which is a sliding fit in a small hole drilled in the shoe. The outer portion of the end of each shoe is screwed, and carries a large nut hearing against • the outer face of the cam plate, so that Unscrewing this nut has the same effect as placing packing he, tween the cam and the shoe. A locking • device is provided by four steel balls, carried in countersunk holes in the faces of the nut and cam plate. Tubular-spoked cast-steel wheels running on Skefko hall races gra provided both front and rear, and spring loaded felt washers prevent oil leakage. A compensator, consisting of a slide fitting right across the chassis and resting on the tops of the side Members, is used for the hand`brake, and the adjustment of the side sods is now at thereat end, being more accessible when the body is in position. Although not shown on the particular

chassis we illustrate, the rear springs will be of the special N type, which automatically adjust themselves to theload. These springs enable a considerable saving to be made in the.material employed, and the vehicle rides just as well unladen as laden, whilst experiments have proved that the rebound after passing throagli pot-holes is much reduced. TheSimple arrangement of. the,se .springa can best he 'seen by referring to the drawing which we reprOduce.

• Owing-to the forward construction, the steering drop arm and its • connection work across the chassis instead of longitudinally..: This has proved an advantage in that. »c shock is transmitted to the steering wheel from the road wheels and there is less angularity. The ball joints and many other parts where there is 'rocking motion, but not actual turning, are provided with oil-less bushings, which have prc ved quite satisfactory.

Petrol is supplied from a 20-gallon tank slung under the rear of the chassisframe to an Autovac carried on the dash. To prevent the possibility of choking at the carburetter, the inner tank of the Autovac is surrounded by a large sieve with 35 sq. ins, of surface. This is only one of the many points where it is obvious that attention to detail has been displayed.

A few of the maid dimensions will be of interest :—Wheelbase, 11 ft. and 12 ft. 6 ins.; width over hub caps, 6 ft.; length behind dash, 16 ft. and 17 ft. 6 ins. ; driver's seat to end of chassis, 12 ft. 9 ins. and 14 ft. 3 ins.; over-all length, 16 ft. 9 ins. and 18 ft. 3 ins. The chassis is designed to carry a net load of two tons on solid tyres, and on the long wheelbase chassis, with pneumatic tyres, 20-25 passengers.