MODERNIZING A LONDON

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

X FOR HEAVY BURDENS.

0 .NE OF OUR national characteristics is to decry our own efforts, and this applies very strongly in the case of the wonderful network of roads which spreads over the whole of the country. In spite of all that has been said to the contrary, • there is no doubt that our road system is one of the finest in the world, and the surfaces compare very favourably with those existing elsewhere.

Naturally, the vast increase hi the use of mechanical road transport has caused excessive wear and, in some caseS, the crumbling of road foundations, but, fortunately, the authorities controlling the matter have not been asleep, and everywhere we see the greatest signs of activity in road modernization and reconstruction, and there is certainly no comparison between the roads of to-day and those of only a few years ago, after their enforced neglect during the war.

It is of little use building a house upon an insecure foundation, and in the same way it is useless to lay a good surface on a foundation not strong enough to bear the traffic which the road will have to carry. Many of the thoroughfares of London have concrete foundations 30 or 40 years old, and, although these are fairly thick, they have rotted in places and have . been so of kin patched as to be of unequal strength throughout, with the result that depressions constantly form. A typical example of this is afforded by the stretch' of Holborn lying between the junction of Kingsway and Southampton Row and Gray's Inn Road, where it meets the City boundary. This stretch of roadway is now being reconstructedboth as regards foundation and surfacing. .

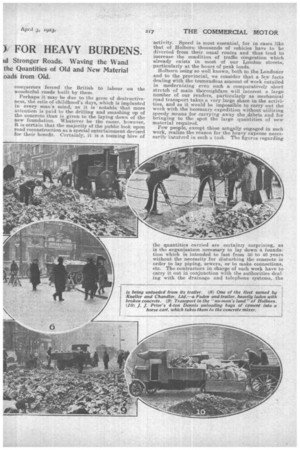

The work of breaking up and removing the old surfacing and the concrete foundation has interested thousands of spectators amongst the public. Possibly this is due to.the spirit of road construction fostered in our remote ancestors by the Romans when these conquerors forced the British to labour on the wonderful roads built by them.

Perhaps it may be due to the germ of destructiveness, the relic of childhood's days, which is implanted in every man's mind, as it is notable that more attention is paid to the drilling and smashing up of the concrete than is given to the laying down of the new foundation. Whatever be the cause, however, it is certain that the majority of the public look upon road reconstruction RS a special entertainment devised for their benefit. Certainly, it is a teeming hive of

activity. Speed is most essential, for in cases like that of Holborn thousands of vehicles have to be diverted from their usual routes and thus tend to increase the condition of traffic congestion which already exists in most of our London streets, particularly at the hours of peak loads.

Holborn being so well known, both to the Londoner and to the provincial, we consider that a few facts dealing with the tremendous amount of work entailed in modernizing even such a comparatively short stretch of main thoroughfare will interest a large number of our readers, particularly as mechanical road transport takes a very large share in the activities, and as it would he impossible to carry out the work with the necessary expedition without utilizing speedy means for carrying away the ,debris and for bringing to the spot the large quantities of new material required. Few people' except those aetiLally engaged in such work, realize the reason for the heavy expense necessarily incurred in such a task. The figures regarding the quantities carried are certainly surprising, as is the erganiza.tion necessary to lay down A foundation which is intended to last from 30 to 40 years without the necessity for disturbing the concrete in order to lay piping, sewers, or to make connections, etc. The contractors in charge of such work have to carry it out in conjunction with the authorities dealing with the drainage and telephone systems, the

Metropolitan Water Board, the gas and electricity companies, and any others to whom the subsoil of a road usually forms a happy hunting ground. Once the necessary arrangements have been carried out, active operations begin on the removal of the old crust and the foundation. Either a portion or all of the road is barred off to through traffic and only vehicles which actually have business in the road allowed access, and this only for a time. If the surface material be asphalt, as in the case of Holborn, this is sold to one of the companies who provide this material. That of Holborn was sold to the Ragusa Asphalte Co., Ltd., and was carted away by the Foden steam wagons and trailers, Maudslay lorries, etc., owned by the Val de Travers Asphalte Paving Co., Ltd.

The area of Holborn is 10,000 sq. yds. between the points previously mentioned, and the thickness of the asphalt was i ins. This old asphalt is reground and mixed with new material, when it can again be used for resurfacing work. As the crust is removed work is commenced with pneumatic drills on the concrete foundation, and

the rapidity with which this can be broken up is surprising, thr ee drills and six men, of whom three clear away the debris, doing as much work as was previously done by 24 men. These drills are not used so much to save labour as to save time, and they obtain their supply of air from IngersollRand stationary petrol engines and compressors.

The broken concrete is then loaded into steam and petrol lorries and trailers of various types, and is sent to different parts of London and the country for the making of arterial roads for the Ministry of Transport. Some goes so far out as 10 miles from Southend, other loads are sent to Chiswick, Brentford, Lewisham, etc. and it must be remembered that the material is taken out by lorry the whole of the way. In this connection Holborn accounted for3,500 cub. yds. solid, which increased by nearly one-third When broken up. The average lorry carries 5 cub. yds., and the lorry with trailer 10 cub. yds. Many are the difficulties which are encountered. Old pipe lines, the knowledge of the existence of which has been last, may be severed, and forgotten tunnels exposed. For instance, at the upper part of Holborn, one tunnel, 13 ft. deep, was broken into ; this is probably a portion of the old post office tunnel built many years ago.

Much of our information with regard to the quantities of materials carried was obtained from Mr. E. J. Harris, general manager of the Acme Flooring and Paving Ca. 090A Ltd., of Gainsborough Road, Victoria Park, London, E. 9, and while we were actually chatting with him about the matter one of his men came to report that they had broken into

B34 another tunnel at the bottom of Gray's Inn Road. Many of these openings are old sewers which have been timbered over and the timbers have rotted with. time. In such cases they have to be filled up before the work of laying a new concrete foundation can be carried out.

The new concrete is mixed on the spot, being made up of ballast dredged out of the Thames south of Gravesend and out of the Ham River so.uth of. Brentford. The cement is manufactured at Sittingbourne in Kent, and is brought up by barges to Poplar and thence by lorries to the scene of operations, where it is all mixed together in a huge mixing machine, which is shown in one of our illustrations. The cement required weighs between 500 tons and 600 tons, and 11 sacks go to the ton.

The concrete is most carefully laid, and embodies B.R.C. fabric, which consists of steel rods and wires welded together to form a kind of mat, so that, to all intents and purposes, the road foundation is homogeneous, and the concrete is strengthened and. prevented from cracking 'by the steel fabric, which also helps in distributing t h e loads..

The finishingoff of the foundation is most careI fully performed, ; the upper surface being of specially fine' qualitymaterial, c,arefull y smoothed down b y means o f planks cut to the camber required,' -half of the road' being done at a -time. After this the concrete is allowed to harden and dry, and is then ready for the surfacing of wood blocks;' These blocks are ' made from Swedish timber inported in the shape of planks, which are cut into the standa.rd-size blocks. After cutting, the blocks a r e creosote& under pressure, drained and transported to the works. For Holborn the lumber of blocks required amounts to 500,000, and as 1,000 blocks go to the tpn, and the lorries carry approximately four tons, this means 125 lorry loads for the wood pairing alone.

Finally, after the blocks have been laid they are tarred over and covered with grit. The last-named material assists in preventing the rubber-tyred vehicles from skidding when the paving is wet, as the grit grips the treads. All this seems to entail a vast expenditure of money and labour, and it may he questioned by some as to whether it is worth the trouble taken, but it must be remembered that a good foundation of the type laid in Holborn may lad nearly half a century (providing that there are no openings by other companies), and that the wood surfacing should have a life of from 14 to 16 years and it can then easily be relaid at a much reduced 'cost.

We have turned the searchlight on one particular roadway in London because it happens to be so well known, but it must be remembered that such scenes are occurring in many parts throughout the country.