• In some Californian cities, and in Hong Kong, motorists

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

can be fined for failing to carry a full quota of passengers during rush hours. In Lagos, Nigeria odd and even number-plated vehicles are forced to take turns on the road on alternate working days.

In most cases such draconian measures are applied only to small people-carriers and light vehicles, but how much longer will it be before authorities take a long hard look at large, general haulage vehicles covering long distances carrying nothing but fresh air?

Any scheme which can improve the operational efficiency of commercial transport by 50% or more and make a contribution towards easing traffic congestion deserves more than just a second glance. And for vehicles on supermarket supply and express parcels work, purpose-built twin-deck semi-trailers can achieve both objectives.

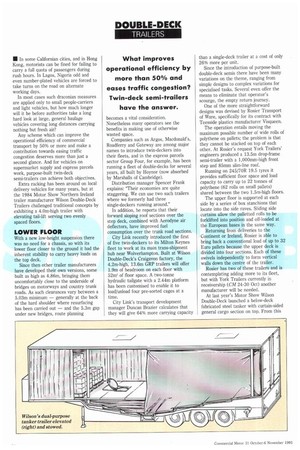

Extra racking has been around on local delivery vehicles for many years, but at the 1984 Motor Show Northern Ireland trailer manufacturer Wilson Double-Deck Trailers challenged traditional concepts by exhibiting a 4.0m-high trailer with elevating tail-lift serving two evenly spaced floors.

With a new low-height suspension there was no need for a chassis, so with its lower floor closer to the ground it had the inherent stability to carry heavy loads on the top deck.

Since then other trailer manufacturers have developed their own versions, some built as high as 4.86m, bringing them uncomfortably close to the underside of bridges on motorways and country trunk roads. As such clearances vary between a 5.03m minimum — generally at the back of the hard shoulder where resurfacing has been carried out — and the 5.3m gap under new bridges, route planning becomes a vital consideration.

Nonetheless many operators see the benefits in making use of otherwise wasted space.

Companies such as Argos, Macdonald's, Roadferry and Gateway are among major names to introduce twin-deckers into their fleets, and in the express parcels sector Group Four, for example, has been running a fleet of double-decks for several years, all built by Hoynor (now absorbed by MarshaIls of Cambridge).

Distribution manager Spencer Frank explains: 'Their economies are quite staggering. We can use two such trailers where we formerly had three single-deckers running around."

In addition, he reports that their forward sloping roof sections over the step deck, combined with Aerodyne air deflectors, have improved fuel consumption over the trunk road sections.

City Link recently introduced the first of five twin-deckers to its Milton Keynes fleet to work at its main trans-shipment hub near Wolverhampton. Built at Wilson Double-Deck's Craigavon factory, the 4.2m-high, 13.6m GRP trailers will offer 1.9m of headroom on each floor with 52m2 of floor space. A two-tonne hydraulic tailgate with a 2.44m platform has been customised to enable it to load/unload four pre-sorted cages at a time.

City Link's transport development manager Duncan Brazier calculates that they will give 64% more carrying capacity than a single-deck trailer at a cost of only 26% more per unit.

Since the introduction of purpose-built double-deck semis there have been many variations on the theme, ranging from simple designs to complex variations for specialised tasks. Several even offer the means to eliminate that operator's scourge, the empty return journey.

One of the more straightforward designs was devised by Rosier Transport of Ware, specifically for its contract with Teesside plastics manufacturer Visqueen.

The operation entails moving the maximum possible number of wide rolls of polythene on pallets; the problem is that they cannot be stacked on top of each other. At Rosier's request York Trailers' engineers produced a 13.5m drop-frame semi-trailer with a 1,000mm-high front step and 85mm slim-line roof.

Running on 245/70R 19.5 tyres it provides sufficient floor space and load capacity to carry up to 22 tonnes of polythene (62 rolls on small pallets) shared between the two 1.5m-high floors.

The upper floor is supported at each side by a series of box stanchions that locate into the side raves. Sliding side curtains allow the palletted rolls to be forklifted into position and off-loaded at the European bases in the same way.

Returning from deliveries to the -Continent or Ireland, Rosier is able to bring back a conventional load of up to 32 Euro pallets because the upper deck is divided into four sections. Each of these swivels independently to form vertical walls down the centre of the trailer.

Rosier has two of these trailers and is contemplating adding more to its fleet, but with York Trailers currently in receivership (CM 24-30 Oct) another manufacturer will be needed.

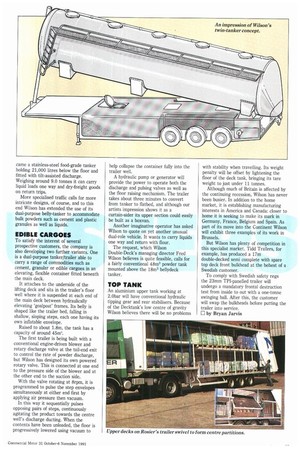

At last year's Motor Show Wilson Double-Deck launched a below-deck fabricated steel tanker with curtain-sided general cargo section on top. From this came a stainless-steel food-grade tanker holding 21,000 litres below the floor and fitted with tilt-assisted discharge. Weighing around 9.0 tonnes it can carry liquid loads one way and dry-freight goods on return trips.

More specialised traffic calls for more intricate designs, of course, and to this end Wilson has extended the use of its dual-purpose belly-tanker to accommodate bulk powders such as cement and plastic granules as well as liquids.

To satisfy the interest of several prospective customers, the company is also developing two further variants. One is a dual-purpose tanker/trailer able to carry a range of commodities such as cement, granular or edible cargoes in an elevating, flexible container fitted beneath the main deck.

It attaches to the underside of the lifting deck and sits in the trailer's floor well where it is suspended at each end of the main deck between hydraulically elevating `goalpose frames. Its belly is shaped like the trailer bed, falling in shallow, sloping steps, each one having its own inflatable envelope.

Raised to about 1.8m, the tank has a capacity of around 45m3.

The first trailer is being built with a conventional engine-driven blower and rotary discharge valve at the tail-end exit to control the rate of powder discharge, but Wilson has designed its own powered rotary valve. This is connected at one end to the pressure side of the blower and at the other end to the suction side.

With the valve rotating at 8rpm, it is programmed to pulse the step envelopes simultaneously at either end first by applying air pressure then vacuum.

In this way it sequentially pulses opposing pairs of steps, continuously agitating the product towards the centre well's discharge ducting. When the contents have been unloaded, the floor is progressively lowered using vacuum to help collapse the container fully into the trailer well.

A hydraulic pump or generator will provide the power to operate both the discharge and pulsing valves as well as the floor raising mechanism. The trailer takes about three minutes to convert from tanker to flatbed, and although our artists impression shows it as a curtain-sider its upper section could easily be built as a bolo/an.

Another imaginative operator has asked Wilson to quote on yet another unusual dual-role vehicle. It wants to carry liquids one way and return with flour.

The request, which Wilson

Double-Deck's managing director Fred Wilson believes is quite feasible, calls for a fairly conventional 48m3 powder tank mounted above the 18m3 bellydeck tanker.

An aluminium upper tank working at 2.0bar will have conventional hydraulic tipping gear and rear stabilisers. Because of the Decktank's low centre of gravity Wilson believes there will be no problems with stability when travelling. Its weight penalty will be offset by lightening the floor of the deck tank, bringing its tare weight to just under 11 tonnes.

Although much of Britain is affected by the continuing recession, Wilson has never been busier. In addition to the home market, it is establishing manufacturing interests in America and Canada: closer to home it is seeking to make its mark in Germany, France, Belgium and Spain. As part of its move into the Continent Wilson will exhibit three examples of its work in Brussels.

But Wilson has plenty of competition in this specialist market. Tidd Trailers, for example, has produced a 17m double-decked semi complete with spare top deck front bulkhead at the behest of a Swedish customer.

To comply with Swedish safety regs the 23mm TPI-panelled trailer will undergo a mandatory frontal destruction test from inside to out with a one-tonne swinging ball. After this, the customer will swap the bulkheads before putting the trailer into service.

0 by Bryan Jarvis