Blown 500s for Lynx and Bison

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

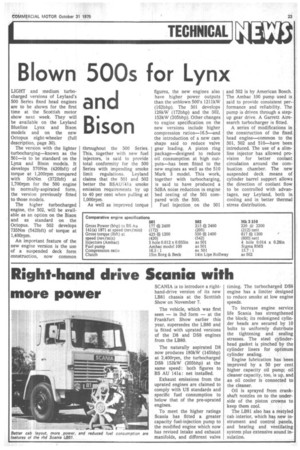

LIGHT and medium turbocharged versions of Leyland's 500 Series fixed head engines are to be shown for the first time at the Scottish motor show next week. They will be available on the Leyland Blueline Lynx and Bison models and on the new Octopus eight-wheeler (full description, page 30).

The version with the lighter turbocharging—known as •the 501—is to be standard on the Lynx and Bison models. It develops 570Nm (4201bft)• of torque at 1,200rpm compared with 504Nm (372Ibft) at 1,700rpm for the 500 engine in normally-aspirated form, the version previously fitted to those models.

The higher turbocharged engine, the 502, will be available as an option on the Bison and as standard on the Octopus. The 502 develops 735Nm (5421bft) of torque at 1,40Orpm.

An important feature of the new engine version is the use of a suspended deck form construction, now common throughout the 500 Series. This, .together with new fuel injectors, is said to provide total conformity for the 500 Series with impending smoke limit regulations. Leyland claims that the 501 and 502 better the BSAU141a smoke emission requirements by up to 40 per cent when pulling at 1,00Orpm.

As well as improved torque figures, the new engines also have higher power outputs than the unblown 500's 1211kW (162bhp). The 501 develops 128kW (172bhp) and the 502, 153kW (205bhp). Other changes to engine specification on the new versions include higher compression ratios-16.5—and the introduction of a new cam shape said to reduce valve gear loading. A piston ring package—designed to reduce oil consumption at high outputs—has been fitted to the new engines as well as the 510 Mark 3 model. This work, together with turbocharging, is said to have produced a 5dBA noise reduction in engine bed testing of the 501 compared with the 500.

Fuel injection. on the 501 and 502 is by American Bosch. The Ambac 100 pump used is said to provide consistent per-. formance and reliability. The pump is driven through a stepup gear drive. A Garrett Airesearch turbocharger is fitted.

A series of modifications in the construction of the fixed head engine—common to the 501, 502 and 510—have been introduced. The use of a slimline injector has allowed provision for better coolant circulation around the combustion chamber. The new suspended deck means of cylinder barrel support allows the direction of coolant flow to be controlled with advantages, say Leyland, both in cooling and in better thermal stress distribution.