No Expense Spared

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Says Ashley Taylor, A.M.I.R.T.E.

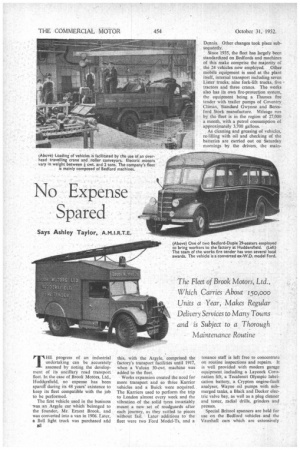

THE progress of. an industrial undertaking can be accurately assessed by noting the development of its ancillary road transport fleet. In the case of Brook Motors, Ltd., Huddersfield, no expense has been spare& during its 48 years' existence to keep its fleet compatible with the job to be performed.

The first vehicle used in the business was an Argyle car which belonged to the founder, Mr. Ernest Brook, and was converted into a van in 1906. Later, a Bell light truck was purchased add

this, with the Argyle, comprised the factory's transport facilities until 1917, when a Vulcan 30-cwt. machine was added to the fleet.

Works expansion created the need for more transport and so three Karrier vehicles and a Buick were acquired. The Karriers used to perform the trip to London almost every week and the vibration of the solid tyres invariably meant a new set of mudguards after each journey, as they rattled. to pieces without fail. Later additions to the fleet were two Ford Model-Ts, and a Dennis. Other changes took place subseq neatly.

Since 1935, the fleet has largely been standardized on Bedfords and machines of this make comprise the majority of the 24 vehicles now employed. .Other mobile equipment is used at the plant itself, internal transport including seven Lister trucks, nine fork-lift trucks, five tractors and three cranes. The works also has its own fire-protection system, the equipment being a Thames fire tender with trailer pumps of Coventry, Climax, Standard Gwynne and Beresford Stork manufacture. Mileage run by the fleet is in the region of 27,000 a month, with a petrol consumption of approximately 3,700 gallons.

As cleaning and greasing of vehicles, re-filling with oil and checking of the batteries are carried out on Saturday mornings by the drivers, the main tenance staff is left free to concentrate on routine inspections and repairs. It is well provided with modern garage equipment including a Layeock Coronation lift, a Tecalemit Olympic lubrication battery, a Crypton engine-fault analyser, Wayne oil pumps with submerged tanks, a Black and Decker electric valve bay, as well as a plug cleaner and tester, radial drills, grinders and presses.

Special Britool spanners are held for use on the Bedford vehicles and the Vauxhall cars which are extensively

• used by the outside staff; In order to minimize the time that vehicles need to be kept off the road, some use is made of sub-assemblies, there always being a Bedford engine in stock together with Bedford and Vauxhall cylinder heads.

Units of the fleet operating from the works include four Bedford 5-tonners, two Bedford. 3-4-tonners, one Bedford 2-3-tonner, one -Austin 2-3-tonner, two Bedford short-wheelbase tippers, a Bedfbrd-Scammell articulated van and semitrailer, three 30-cwt. vans, five Bedford 12-cwt. vans, and two Bedford-Duple coaches with 29-seat bodies. In addition, vans are stationed at Liverpool, Manchester and London for service purposes.

Brook Motors, Ltd., builds roughly 250,000 electric motors a year, many of which go to. overseas markets. About150,000 a year are carried by the factory fleet, the units varying 'in size from about i-cwt. to 2 tons. The vehicles offer_a daily service to customers in the Wakefield, Ossett, Morley, Leeds, Skipton, Bradford, Keighley, Halifax and Ht,mslet districts. Deliveries are made four times a week to the outer circle that embraces Sheffield, Chesterfield, Rotherham and Barnsley, whilst Manchester. Stockport, Burnley, Todmorden, Rochdale and similar areas in Lancashire are served weekly.

Two of the 5 -tonncrs each make two trips weekly to the industrial areas of the Midlands, departing on Monday Morning and returning on Wednesday night, being re-loaded for departure on Thursday morning and returning on Saturday. On each of the three-day trips as many as 50 deliveries may be accomplished.

Nearly 20 miles any from Huddersfield is Barnsley, a colliery centre where availability of female labour has for many years been above the average for industrial areas, and an additional plant was opened there some years ago. At the time of writing another entirely new works is under construction there.

In the past, the system has been to use one of the Bedford 5-ton vans for transport between the two works and this vehicle has made 15 round trips a week, carrying winding materials and stator frames to Barnsley, bringing the wound stators back to Huddersfield for use at the main works. In this connection it is anticipated that articulatedvehicle-working will shortly be instituted with a Bedford tractor and three semi-trailers, for which a special dock has been built at the new Barnsley factory.

Workers are also drawn from Barnsley for employment at Huddersfield and the two coaches are employed for this

duty. They have three or four pickingup points in Barnsley and, of course, carry their passengers direct to the works at Huddersfield.— By this means certain and comfortable travel is pro. vided for the workers, whilst the local transport systems are relieved of some degree of pressure at the peak hours.

The opening of the new Barnsley works may shift the emphasis to some extent and it is possible that future needs, may be rather for the transfer of key personnel from Huddersfield to Barnsley than the movement in the reverse direction which has taken place in the past.

Older readers may possibly recall that comment was made in the pages of "The Commercial Motor" before the war, on the possibility of road transport being employed to carry work to the workers rather than to bring workers to a factory. In the immediate postwar years, Brook Motors, Ltd., employed this system to good effect, using the services of married women who had worked in the factory in the past and who gladly accepted the chance of earning regular money at home. In each case, a small bench, measuring approximately 2 ft. by 3 ft., was supplied by the company, and each day components and materials were delivered all round Huddersfield by a van which alto collected the finished assemblies.

In this way a substantial additional output was achieved, but more recently re-organization has enabled the processes-concerned to be concentrated at the main factories. Where the factory is fully engaged, however, the plan of taking the work to the workers has obvious advantages for, in addition to the fact that a greater labour force can be deployed, employment is made more attractive because workers are relieved of the necessity of travelling on public transport at the rush hour.

The extensive employment of works and fork-lift trucks maintains a -high degree of efficiency in the handling of materials and finished products within the factory. Awards won in local competition testify to the high standards attained by the Brook Motors' fire tea in and their equipment.