The

Page 38

Page 40

Page 41

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

Diamond years

This year marks the 60th anniversary of Cheshire-based body and trailer manufacturer Cartwright Group

Words: Kevin Swallow

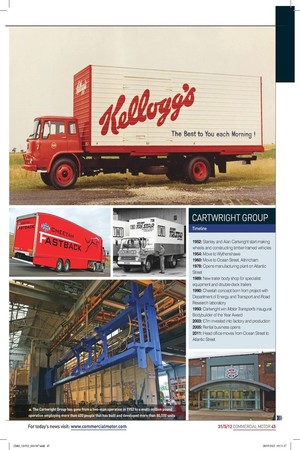

In 60 years of assembling, building, engineering and manufacturing, Cheshire-based body and trailer producer Cartwright Group has spanned three generations and built more than 80,000 units.

Perhaps it’s no accident that Cartwright means ‘someone who makes carts’. The company has gone from a two-man operation started in 1952 by Stanley Cartwright and his son Alan from a barn in Altrincham making wheels and timber-framed vehicles, to a £78m turnover manufacturing and rental business spanning 38 acres and employing more than 410 people.

In 1954 the pair opened their first workshop in Wythenshawe, Manchester. Alan’s brother Peter joined the business in 1960 and the company, S Cartwright & Sons (Coachbuilders) Limited, moved to Ocean Street, Altrincham.

Throughout the 1960s and into the 1970s customers such as Kellogg’s, BRS, Storage & Haulage (which became TDG and was subsequently bought by Norbert Dentressangle) and Schreiber Furniture wanted rigid bodywork and demountable bodies.

“Demountables was the name of the game in the 70s, for ourselves with builders Dobson Demounts and Ray Smiths. We became a builder for Dobson and used to put bodies on their chassis,” he says.

Cartwright acquired Nottingham-based Dobson Demount in 1978 and its design is still part of the range of products.

In 1975 Cartwright & Sons started to build and assemble trailers. “We started making frameless trailers working for truck builder Scammell, based in Watford. They would send us the running gear, axles, fifth-wheel plate and landing legs, and we would put a body and a Scammell plate on it, which is how the trailer side of the business started. It was a Scammell chassis with a Cartwright body.” Trailers would be the next level for the company, but it would be done without co-founder Stanley, who passed away in 1977. The following year, York Trailers bought the rights to the Scammell trailer so it could supply trailers for a National Carriers contract and York stopping supplying running gear to Cartwright. “So we employed Scammell’s engineer and started to build our own trailers,” says Peter. To do this the company opened a new site on the adjacent Atlantic Street specifically for trailer chassis and demount bodies, and production started in 1979.

In 1983 the Cartwright business welcomed its third generation when Alan’s sons joined. John, then aged 18, started in the trailer chassis, hydraulic department and fabrication department, and the following year 16-year-old Steven joined the floor in the body shop. In 1994 Peter’s son Mark joined the company aged 22, with an engineering degree from Nottingham University.

When co-founder and chairman Alan passed away last year, aged 73 and having put 59 years into the business, Peter, the current director and company secretary, was left as the final link to the company’s beginning.

“I have been here 52 years – I always said I didn’t want to be the biggest trailer builder in the UK because most of them disappear, like Crane Fruehauf, York Trailers, etc, but we are a bit different because we diversify across a range of products,” he says.

Aerodynamic trailers

That diversity included the first aerodynamic trailer that stemmed from work with the Department of Energy and the Transport and Road Research Laboratory in 1990. It developed into the Cheetah trailer, and 20 years later evolved, thanks to Computational Fluid Dynamics and a partnership with Manchester Metropolitan University, into the Cheetah Fastback.

Using a variable air suspension system that lowers the running height of the trailer to reduce drag, it produced a 10% fuel saving in independent trials at the MIRA Proving Ground. This led to orders with TNT and Yodel, to name two, and in 22 years the company has built more than 1,100 Cheetah products.

A key element has been Cartwright Rentals, which began in 2005. The demise of Transrent, a major customer that had been taking Cartwright Trailers since 1998, created a major expansion of the rental fleet with 600 trailers returning to Wythenshawe, which helped bring Cartwright a lot of new customers, admits Peter.

“We see trailers from cradle to grave as they come back to the rental business, which has grown to six sites and more than 5,000 trailers,” he says.

Peter is still involved with the finance, rental and purchasing. “Mark heads up the procurement team – it’s key to the job,” he says. “To build a brand it can take a long time; we have customers who have supported Cartwright, have been loyal and stayed with the company through the years.

“People often said that to be established we had to be in Glass’s Guide. Cartwright became a national company, rather than a local manufacturer, towards the end of the 1990s,” he says.

When Cartwright Group transferred its head office last year from Ocean Street onto Atlantic Street, the entire business was reunited on a single site for the first time since 1978. n

FLEET SPEC AND LONGER TRAILERS

Minimising downtime Cartwright Group has launched a fleet specification for its product range designed to minimise downtime when it comes to damage repair and planned maintenance procedures. Holland says: “The way it has been created is by looking at the information we have gathered from the rental fleet for damage and maintenance, and from that develop a fleet trailer.

“The idea is that the trailer comes back with less damage and maintenance required, and the whole life cost remains low. The purchase price is one thing, but the maintenance and damage cost can exceed that during its life so that is what we are concentrating on.” The majority of trailers returning to Cartwright that go into the rental sector are between five and seven years old. Cartwright says: “Fleet spec reduces the refurbishment process. With curtainsided trailers, the most popular in the market, all you want to do is replace the curtains and doors and away it goes; they then go for another five years, then at 12 years you have a cheap rental/disposal situation.” Fleet specification could become the majority choice for many of the trailers produced by the manufacturer, and already operators are specifying it as part of their requirements.

Cartwright is building 130 longer semi-trailers for customers, all 15.65m long, for the likes of United Biscuits, Asda, Royal Mail, CM Downton, Pets@Home and EAS.

Holland says there are pros and cons whether operators choose command rear-steer, and the company is also quoting for the self-steering axle. “Self-steer is lighter and cheaper but is not as user-friendly as the command rear-steer, which is easier to operate and saves on tyre wear although it is heavier and more expensive. These days we find that customers are even more informed than ever and therefore can make an informed decision on their choice of longer semi-trailer options. However, our recommendation would be command rear-steer.”

60 YEARS AGO...

• Princess Elizabeth, Duchess of Edinburgh, succeeds George VI as head of state following his death at age 56 after a long illness; • European Parliament Assembly, which becomes the European Union, holds its inaugural meeting with six members; Belgium, France, Germany, Luxembourg, Italy and the Netherlands; • Rocky Marciano knocks out Jersey Joe Walcott to win the World Heavyweight Title; • Gary Cooper wins Academy Award for best actor in High Noon; • New Musical Express begin UK Singles Chart, with ‘Here In My Heart’ sung by Al Martino as the first ever number one; • British Motor Corporation, Holiday Inn, and future steel conglomerate Jindal Group all start trading.

INVESTMENT AND APPRENTICES

Manufacturing is now housed exclusively on one site at Atlantic Street, and Cartwright Group is set to streamline production and recruit apprentices.

Key investment at the beginning of the manufacturing process, replacing a plasma punching machine with a new £800,000 laser metal-cutting machine, has sped up production.

The 4.4kW laser cutting machine can work on components up to 6.5m in length. Group sales director Darren Holland says the machine allows Cartwright to cut its own pieces. “It means more work, now approximately 75%, can be done in-house,” he says.

Production has also been broken down into more specific stages that are better time managed, which has doubled the daily chassis output to 12 using the same people within the same time span.

More investment will see the monorail system, which takes the chassis into shot-blasting and painting, extended into axle assembly and panel production.

Pre-delivery inspection (PDI) is now a dedicated scrutiny stage of manufacturing, instead of its previous role as a ‘catch all problems’ department, with any issues filtered back into the production line.

“There are only clipboards and decals in the PDI area now, which has helped improve production standards,” he says. “No one wants to see a product they have worked on return to their production stage.” More than £2m has been invested into improving production, and there is more to come as parts and stock departments, still based on Ocean Street, will be re-housed on Atlantic Street as space is freed up.

In order to help bolster its workforce the company has also announced its intentions to recruit 70 apprentices over the next two years to support the company’s expansion.

Cartwright Group has developed a two-year apprenticeship programme in engineering with Stockport College. Director John Cartwright says promising recruits will have the opportunity to progress to an Advanced Apprenticeship to City & Guilds level 3 and ultimately to HNC/HND engineering qualifications.

“Skilled workers are the lifeblood of our company, and some of our most senior managers began their careers as engineering apprentices on the shop floor.

“By taking on more apprentices here at Cartwright, we are ensuring that the highly prized engineering skills that are necessary for our business are passed on to a new generation of workers,” he says.

The apprenticeships target 16to 18-year-olds, and the first phase will see 40 apprentices selected in June and July starting in August.

“We want to nurture people with the ability to succeed and drive our company forward,” says Cartwright.

Patricia Byrne, assistant principal at Stockport College, says apprentices will learn very practical skills in workshops which will give them the right experience to develop a long-term career at Cartwright, “at a time when the UK is going back into recession”.

CARTWRIGHT GROUP

Timeline 1952: Stanley and Alan Cartwright start making wheels and constructing timber-framed vehicles 1954: Move to Wythenshawe 1960: Move to Ocean Street, Altrincham 1978: Opens manufacturing plant on Atlantic Street 1989: New trailer body shop for specialist equipment and double-deck trailers 1990: Cheetah concept born from project with Department of Energy and Transport and Road Research laboratory 1993: Cartwright win Motor Transport’s inaugural Bodybuilder of the Year Award 2003: £7m invested into factory and production 2005: Rental business opens 2011: Head office moves from Ocean Street to Atlantic Street