Horses for courses by computer

Page 27

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

by Johnny Johnson

A PROBLEM which faces all operators is that of vehicle performance comparison and selection. It is not a simple matter to be sure that the vehicle bought is the right one for the job and, even after it has been in service for some time, the absence of information about the performance of comparative vehicles makes evaluation difficult.

From the former batch testing procedures of British Road Services Ltd, however, a system is being evolved, using a computer, not only to evaluate vehicle performance but also to monitor the function of a number of individual components.

Identifying code

The pilot scheme has been operating at two depots — Newcastle upon Tyne and Barnsley of North Eastern British Road Services and is expected to be extended to the other seven constituent companies by next year.

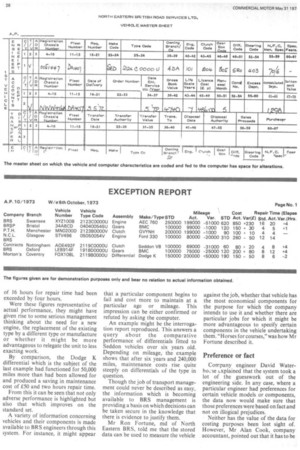

The depots concerned were chosen to provide a good cross-section of the fleet and the work on which it is engaged. Each depot is given an identifying code and each vehicle is also coded according to type and work. Together with other data such as date of purchase, book value, estimated life and so on, this is fed into the computer from a master sheet. This also contains codes which relate to components such as the engine, gearbox, differential and steering gear.

From experience provided by the former batch testing procedures, parameters of component life and maintenance cost are also included in the program so that in case of a component failing before that standard or costing more to overhaul than the figure set, an exceptional report is returned by the computer for management attention. Normal performance data is provided each four-weekly period.

From the exception report reproduced, which contains representative figures for demonstration purposes only, it can be seen that the AEC engine on vehicle XYZIOOB at the Swansea branch was given a standard performance of 250.000 miles. It required attention at 199,000 miles. This revealed a discrepancy between the actual and expected performance of 51,000 miles.

Repair time

Moreover, the standard set for an engine of this type involved the expenditure of £620 on overhaul, but the actual expenditure had been £850 showing that £230 more than had been allowed for had been incurred. Finally, a standard of 16 hours for repair time had been exceeded by four hours.

Were these figures representative of actual performance, they might have given rise to some serious management thinking about the need for a new engine, the replacement of the existing type by a different type or manufacture or whether it might be more advantageous to relegate the unit to less exacting work.

By comparison, the Dodge K differential which is the subject of the last example had functioned for 50,000 miles more than had been allowed for and produced a saving in maintenance cost of £50 and two hours repair time.

From this it can be seen that not only adverse performance is highlighted but also that which improves on the standard set.

A variety of information concerning vehicles and their components is made vvailable to BRS engineers through this system. For instance, it might appear that a particular component begins to fail and cost more to maintain at a particular age or mileage. This impression can be either confirmed or refuted by asking the computer.

An example might be the interrogation report reproduced. This answers a query about the comparative performance of differentials fitted to Seddon vehicles over six years old. Depending on mileage, the example shows that after six years and 240,000 miles, maintenance costs rise quite steeply on differentials of the type in question.

Though the job of transport management could never be described as easy, the information which is becoming available to BRS management is providing a basis on which decisions can be taken secure in the knowledge that there is evidence to justify them.

Mr Ron Fortune, md of North Eastern BRS, told me that the stored data can be used to measure the vehicle against the job, whether that vehicle has the most economical components for the purpose for which the company intends to use it and whether there are particular jobs for which it might be more advantageous to specify certain components in the vehicle undertaking them. "Horses for courses," was how Mr Fortune described it.

Preference or fact

Company engineer David Waterhouse oiplained that the system took a lot of the guesswork out of the engineering side. In any case, where a particular engineer had preferences for certain vehicle models or components, the data now would make sure that those preferences were based on fact and not on illogical prejudices.

Neither has the value of the data for costing purposes been lost sight of. However, Mr Alan Cook, company accountant, pointed out that it has to be evaluated in relation to the assortment of vehicles of varying ages which has been the basis of the data fed into the computer.

Logically, if the company had begun the system with a complete new fleet then certain results, relating to both performance and finance, might be able to be taken at their face value. As it was, the results obtained had to be related to the individual vehicle, its age and mileage. For comparison purposes, the relevant age and mileages of comparable vehicle had to be borne in mind. As the system matures, the vehicles in the fleet will become more directly comparable.

Master sheet

The attraction of the system for Alan Cook is the wealth of information provided in relation to the minimum number of forms used. The master sheet has space for two vehicles and provides for alteration of vehicle characteristics, transfer or disposal. The computer input form is simple and easi. compiled.

The performance data is not the on' useful information provided, howeve for a great deal of the tedium attached I manual compilation of routine returi has been eliminated.

The monitoring report show illustrates the way in which workshc capacity is scheduled and monitorei Here, as an example, the Leeds wonl shop one week last year was schedule to undertake 30 routine maintenan4 jobs but achieved only 25. On the off'', hand, spare capacity was reserved fc three unscheduled jobs but seven we undertaken. In addition the three pr DoE inspections scheduled we successfully completed as were the pai: shop and body shop jobs.

Renewals

The computer also provides warnit of insurance and road fund licen, renewal as well as inspections, Dc testing and so on.

It seems to me that BRS might wc consider making the system available other operators once it has becon established. In this way it could recov some of its own costs while providing useful source of information to tl industry at large.